Alginate Fiber Preparation

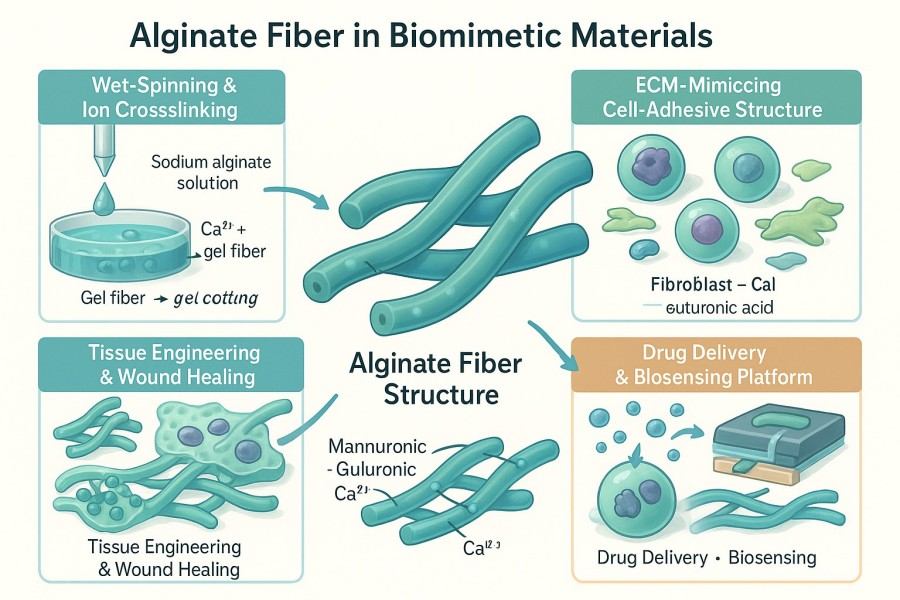

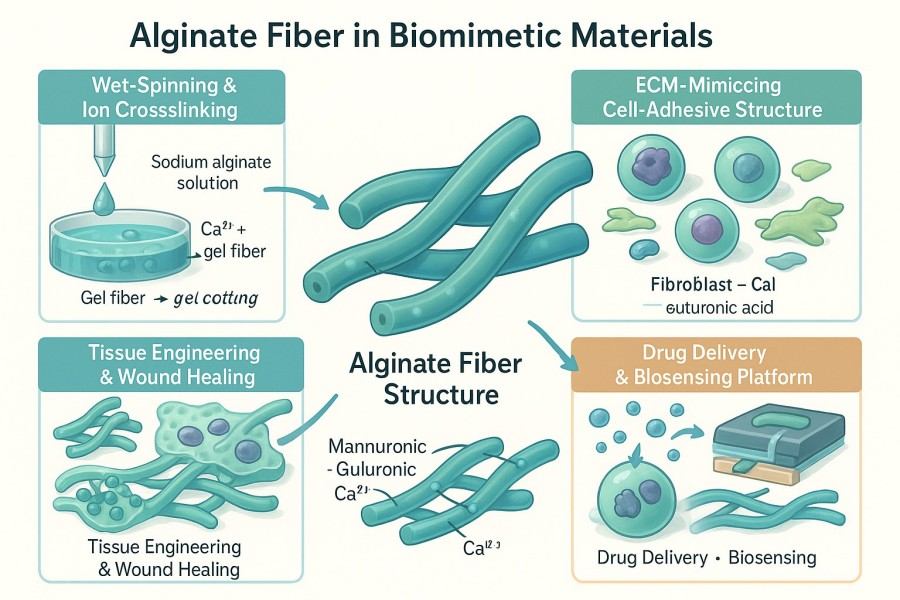

Alginate fibers are biofunctional fibrous materials derived from natural polysaccharide polymers—alginates—through a wet spinning process. Alginates are primarily extracted from the cell walls of brown algae (Phaeophyceae, such as kelp and giant kelp) and are linear, anionic polysaccharides. Due to their unique ionic crosslinking properties, excellent biocompatibility, high hygroscopicity, and biodegradability, alginate fibers have found broad applications in modern medical, bioengineering, and functional textile fields. As a professional supplier of polymer chemicals and monomers, BOC Sciences is dedicated to providing comprehensive alginate fiber preparation and development services to research institutions, development enterprises, and industrial manufacturers. Our services cover the full process—from raw material selection, fiber design, and functional modification to laboratory-scale preparation and industrial production—helping clients accelerate the translation from proof-of-concept to mass production. Whether for tissue engineering scaffolds, drug-controlled release carriers, or biodegradable textile materials, we offer targeted solutions to meet diverse research and production needs.

What We Offer

Alginate Fiber Production Services by BOC Sciences

Leveraging our advanced polymer R&D and production platform, BOC Sciences offers a diverse range of high-performance alginate fibers to meet the multi-level demands of research, functional material design, and industrial-scale production. By controlling the type of metal ion crosslinking, composite material composition, and fiber microstructure, we achieve precise regulation of mechanical properties, water absorption, bioactivity, and controlled release characteristics, providing flexible and customizable solutions for biomimetic material researchers and developers.

Calcium Alginate Fiber

- Offers alginate raw materials with different M/G ratios, allowing precise control over fiber hardness and flexibility.

- Adjustable Ca²⁺ crosslinking concentration for precise tuning of mechanical properties and water absorption.

- Supports laboratory-scale trials to industrial batch production with consistent quality.

- Provides fiber characterization services, including diameter, mechanical properties, and porosity analysis.

Zinc Alginate Fiber

- Crosslinked with Zn²⁺ ions to combine natural antibacterial properties with biodegradability.

- Customizable fiber diameter and microstructure to meet diverse functional requirements.

- Offers composite modification options, including incorporation of nanoparticles or drug molecules.

- Full-process technical guidance from R&D validation to small-scale industrial production.

Silver Alginate Fiber

- Controlled silver ion incorporation enables high antibacterial efficiency with biocompatibility.

- Fiber functionalization services, including regulation of antibacterial strength and release rates.

- Supports porous structure design to enhance drug or bioactive molecule carrying capacity.

- Comprehensive characterization services, including silver content, mechanical performance, and fiber stability.

Sodium Alginate Fiber

- Provides water-soluble fiber solutions suitable for food, edible packaging, and carrier applications.

- Adjustable fiber diameter and dissolution rate to meet different process requirements.

- Compatible with functional active substances, such as probiotics or flavor molecules.

- Offers technical consultation and performance optimization from laboratory-scale trials to mass production.

Composite Alginate Fiber

- Can be combined with cellulose, chitosan, or nanomaterials to enhance mechanical and functional properties.

- Supports functional modifications, such as controlled-release drug carriers or antibacterial composite fibers.

- Provides customized fiber design, including porosity, fiber network density, and mechanical performance.

- Capable of laboratory verification and industrial-scale scaling to ensure stable and controllable composite performance.

Alginate Nanofiber

- Produced via electrospinning, with fiber diameters controllable from nano- to microscale, suitable for high surface area applications.

- Adjustable fiber porosity and alignment for optimized tissue engineering or drug-controlled release performance.

- Supports functional composites, including incorporation of nanoparticles or bioactive molecules.

- Provides complete characterization services, including nanostructure analysis, mechanical properties, and functional evaluation.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Customized Alginate Fiber Preparation and Functionalization Services

BOC Sciences offers robust technical support for the research, development, and production of alginate fibers. Our platform encompasses high-purity raw material selection, fiber preparation processes, functional modification, performance characterization, and quality control, fully meeting the diverse needs of research institutions and enterprises in biomimetic material development. Whether for continuous industrial fibers, nanoscale electrospun fibers, or porous sponge-like fibers, we provide mature preparation solutions and controllable process parameters.

1Material and Raw Material Advantages

- High-purity alginate raw materials: Available from different sources and M/G ratios to suit varying requirements for fiber hardness, flexibility, and water absorption.

- Various functional materials: Including composite polysaccharides, proteins, nanoparticles, and drug molecules for fiber modification.

- Stable supply: High batch-to-batch consistency ensures reproducibility for both laboratory research and industrial production.

2Fiber Type Customization

- Monofilament Fiber: Continuous fibers with uniform diameter and excellent mechanical properties, suitable for sutures and industrial textiles.

- Composite Fiber: Combined with proteins, polysaccharides, or nanomaterials to enhance mechanical strength, functionality, and drug-carrying capacity.

- Porous Fiber: Highly absorbent, porous structures suitable for tissue engineering scaffolds, drug release, and adsorption materials.

- Nanofiber: Electrospun fibers suitable for biomimetic membranes, sensors, and high surface area applications.

3Functional Modification

- Chemical modification: Grafting, etherification, esterification, etc., to enhance fiber performance or introduce specific functions.

- Physical composite: Incorporation of nanoparticles, drug molecules, or antibacterial agents to enhance composite fiber functionality.

- Crosslinking control: Adjustable Ca²⁺, Ba²⁺, Sr²⁺ concentrations and crosslinking time for controlled hardness and release performance.

- Surface functionalization: Film coating or surface modification to confer hydrophilic, hydrophobic, or selective adsorption properties.

4Preparation and Processing Capabilities

- Wet Spinning: Industrial continuous fiber production with uniform diameter and stable mechanical performance.

- Electrospinning: Nanofiber and nonwoven mesh production suitable for tissue engineering, drug release, and biomimetic material studies.

- Freeze Drying: Produces porous sponge-like fibers for adsorption, drug loading, and scaffold applications.

- Air Jet Spinning: Micron-scale fiber production for high-performance functional composite materials.

Characterization

Alginate Fiber Analysis and Characterization Services

BOC Sciences leverages advanced polymer analysis platforms to provide comprehensive testing and quality assurance for research and industrial clients. Our analytical system covers physical properties, chemical structure, functional characteristics, and safety evaluation, ensuring that each batch of alginate fibers meets customer requirements in mechanical strength, pore structure, functional loading, and biocompatibility, providing reliable data support for research validation, product development, and industrial applications.

| Test Category | Test Item | Method | Purpose |

|---|

| Physical Properties | Fiber Diameter | Optical Microscopy, Scanning Electron Microscopy (SEM) | Determine uniformity and microstructure of fibers |

| Fiber Length & Uniformity | Optical Microscopy Measurement | Ensure consistency for processing and applications |

| Mechanical Properties | Tensile Testing, Breaking Strength Test | Evaluate fiber strength and toughness |

| Water Absorption / Swelling Ratio | Water Absorption Experiment | Measure water uptake and porosity of fibers |

| Chemical Properties | Chemical Structure Analysis | FTIR, NMR | Verify chemical composition and functional modifications |

| Metal Ion Content | ICP-OES, Atomic Absorption Spectroscopy | Control crosslinker content and functional characteristics |

| M/G Ratio Analysis | High-Performance Liquid Chromatography (HPLC) | Determine composition ratio related to fiber performance |

| Functional Properties | Drug or Active Molecule Loading | UV-Vis, HPLC | Control loading amount and release characteristics |

| Controlled Release Performance | Drug Release Experiment | Evaluate release rate of drugs or functional molecules |

| Antibacterial Performance | Microbial Inhibition Test | Verify antibacterial or functional activity |

| Safety & Biocompatibility | Biocompatibility | Cytotoxicity Assays (MTT, etc.) | Ensure safety for medical and food applications |

| Biodegradability | Hydrolysis Experiment | Assess fiber degradation under different environments |

Advantages

Advantages of Collaborating with BOC Sciences

- Professional Expertise: Years of deep experience in polymer chemistry and biomaterials, with a technical team skilled in both R&D and industrial-scale production.

- Customization Capability: Offers tailored solutions for monofilament fibers, composite fibers, nanofibers, and porous fibers to meet diverse client requirements.

- Full-Process Services: Covers raw materials, preparation, modification, analysis, characterization, and industrial-scale production, providing one-stop technical support.

- Quality and Controllability: Stable raw material batches, controllable processes, and reliable product performance suitable for research, development, and production stages.

- Flexible Collaboration Models: Capable of handling projects of varying scales, from small-scale trials and validation experiments to mass production, meeting both research and industrial needs.

- Innovative Solutions: Combines advanced polymer technologies with functionalization capabilities to deliver fibers with enhanced mechanical strength, bioactivity, and controlled release properties.

- Technical Guidance and Support: Provides expert consultation throughout the project lifecycle, including process optimization, performance evaluation, and troubleshooting, ensuring efficient project progression and successful outcomes.

Service Process

Full-Process Technical Support for Alginate Fiber Development

BOC Sciences provides comprehensive technical support throughout the entire development cycle. This ensures that every batch of fiber products achieves optimal performance, functionality, and quality. Our services are designed for research institutions, development enterprises, and industrial producers, facilitating efficient translation from laboratory validation to mass production applications.

1Fiber Preparation Process Design

We design optimal preparation processes based on target fiber type, porosity, diameter, and mechanical properties. By integrating wet spinning, electrospinning, freeze-drying, and air-jet spinning techniques, we provide customized process parameters to ensure fibers meet specific requirements in morphology, strength, flexibility, and functionality for both research and industrial applications.

2Raw Material Selection and Design

Precise selection of alginate type, M/G ratio, and composite materials is performed based on project goals, alongside tailored raw material modification strategies. Optimizing raw material properties and combinations ensures that the base fiber characteristics meet the diverse application needs in pharmaceuticals, food, environmental, and biomimetic materials, while guaranteeing reliability and stability in subsequent preparation processes.

3Laboratory Validation and Small-Scale Trials

We provide laboratory-level fiber preparation and characterization services to evaluate the impact of different process parameters on fiber structure and performance. Small-scale trials optimize fiber diameter, porosity, mechanical properties, and functional loading, achieving the best performance combinations and providing reliable technical data for scaling up production.

4Functional Modification and Composites

Chemical or physical modifications are applied based on application requirements, including crosslinking control, nano-composites, and incorporation of active molecules or drugs. Functional design enhances fiber bioactivity, controlled release properties, antibacterial performance, or smart responsiveness, enabling multifunctional applications in pharmaceuticals, food, and biomimetic materials.

5Industrial-Scale Production Support

We assist clients in process scaling, batch production, and quality control to ensure stable and consistent fiber performance in industrial-scale manufacturing. Production optimization guidance addresses potential challenges in uniformity, strength, and functional performance, improving efficiency and product yield.

6Analysis and Characterization Services

Comprehensive testing of physical properties, chemical structure, and functional performance is provided, including fiber diameter, porosity, mechanical properties, drug loading, and release profiling. Accurate characterization ensures that products meet research and application standards, providing reliable data support for functional applications and industrial production.

Applications

Alginate Fiber Application Support for Biomimetic Materials

Due to their natural polysaccharide composition, excellent biocompatibility, and tunable microstructure, alginate fibers have broad application potential in biomimetic materials. Their unique three-dimensional network structure, pore distribution, and functionalizable properties enable the simulation of natural tissue environments, providing structural support, protection, and functional carrier capabilities for diverse biomimetic applications in pharmaceuticals, food, environmental, and smart materials.

Medical and Biomedical Materials

Alginate fibers can be used for tissue engineering scaffolds, where electrospun or porous fiber networks provide an ideal environment for cell adhesion, proliferation, and differentiation. By controlling fiber porosity and crosslinking density, fibers can serve as drug-controlled release carriers, precisely regulating drug release rates. Highly absorbent fibers can be used for wound dressings to accelerate healing, while biodegradable fibers are suitable for surgical sutures, balancing safety and degradability.

Food and Nutritional Materials

In food science, alginate fibers can be used to create edible functional materials as carriers for probiotics or nutrients, enabling stable release and protection of sensitive ingredients. They are also applicable for food packaging and film materials, offering biodegradability and environmental friendliness. Structural design can further regulate food shelf life, flavor release, and physical protection functions.

Environmental and Industrial Applications

Alginate fibers exhibit superior performance in environmental and industrial applications. They can be used to produce adsorbent fibers for removing heavy metals, dyes, and organic pollutants from water. When combined with other polymers, they form high-performance biodegradable composites with optimized structural strength and functionality, meeting environmental and industrial requirements.

Biomimetic Membranes and Smart Materials

Alginate fibers can construct biomimetic fiber structures that mimic the microarchitecture of natural tissues, enhancing mechanical toughness and functionality. Through chemical or physical modifications, fibers can exhibit smart responsiveness, such as reacting to pH, temperature, or ion concentration changes. This makes them suitable for smart drug delivery systems, sensing materials, or functional regulatory materials, driving innovative applications in multiple biomimetic material fields.

FAQs

Frequently Asked Questions

-

What is alginate fiber?

Alginate fiber is a natural fiber made from alginate extracted from brown seaweed. It forms a three-dimensional porous structure through ionic or covalent crosslinking. This structure allows it to hold water, encapsulate drugs, cells, or bioactive compounds, and provide mechanical support. Alginate fibers are biocompatible, biodegradable, and widely used in tissue engineering, wound dressings, drug delivery, functional food carriers, and environmental applications.

-

What are the benefits of alginate fiber?

Alginate fibers offer high water absorption, biocompatibility, and biodegradability. They support cell growth in tissue scaffolds, enable controlled drug or nutrient release, and are environmentally friendly. Their porous structure allows functional modification, such as antimicrobial activity or smart responsiveness. These properties make alginate fibers versatile for biomedical materials, food packaging, environmental filtration, and advanced research applications.

-

What types of alginate fiber are available?

Alginate fibers include calcium alginate, sodium alginate, silver- or zinc-crosslinked fibers, composite fibers, and nanofibers. Each type has unique solubility, mechanical strength, and functional properties. Calcium alginate is stable and strong, sodium alginate is water-soluble, and composites can provide enhanced performance. This variety enables tailored solutions for medical, food, environmental, and smart material applications.

-

What is calcium alginate fiber used for?

Calcium alginate fiber is produced by crosslinking sodium alginate with calcium ions. It has high mechanical strength, chemical stability, and water absorption. These fibers are commonly used in wound dressings, tissue scaffolds, and drug delivery systems. The fiber structure can be tailored to optimize porosity, strength, and release profiles, making it suitable for biomedical, industrial, and environmental applications.

-

What is sodium alginate fiber used for?

Sodium alginate fiber is water-soluble and easy to process. It is used in functional foods, edible films, and as carriers for probiotics or nutrients. Its solubility allows controlled swelling and release of encapsulated substances. Sodium alginate fibers can also be converted into calcium alginate fibers or composites, providing flexibility for applications in food, biomedical, and environmental fields.

-

What is alginate hydrogel fiber?

Alginate hydrogel fiber is a hydrated, three-dimensional fibrous network formed by ionic or covalent crosslinking. It has high water content, porosity, and flexibility, making it ideal for tissue scaffolds, drug delivery, and cell encapsulation. Functionalization with bioactive or stimuli-responsive components enables controlled release and smart material applications, suitable for biomedical, food, and environmental research.