PLGA Microsphere Preparation

PLGA microspheres are micron-sized particles made from poly(lactic-co-glycolic acid) (PLGA). Due to their excellent biodegradability and biocompatibility, PLGA microspheres have attracted wide attention in drug delivery, tissue engineering, and biomimetic materials. By adjusting the material composition, molecular weight, and particle size, PLGA microspheres allow precise control over drug release rate, loading capacity, and targeting performance, making them an essential tool in modern pharmaceuticals, medical devices, and functional materials development. BOC Sciences provides professional PLGA microsphere preparation services, supporting customized R&D from raw material selection, particle size and structural design, to drug loading and functional modification. Through advanced fabrication techniques and strict quality control, we can produce solid, hollow, porous, or core-shell microspheres with high precision and deliver stable, controllable drug release profiles, ensuring reliability for both research and industrial applications.

What We Offer

High-Performance PLGA Microspheres for Your Research

BOC Sciences has extensive experience in the development, preparation, and functional modification of PLGA microspheres. We offer a variety of microsphere structures, including solid, hollow, porous, and core-shell types, and can also develop PEGylated, targeted, or stimuli-responsive microspheres based on customer requirements to achieve smart drug delivery and optimized biomimetic material functionality. Our PLGA microsphere synthesis and preparation services cover raw material selection, process development, particle size and morphology control, drug loading, and functional modification.

PLGA-PEG Microspheres

- Customizable PEGylated microspheres with different PEG molecular weights and ratios.

- Extends in vivo circulation time and reduces immune recognition.

- Supports loading and sustained release of small molecules, proteins, and nucleic acids.

- Can be combined with targeting or stimuli-responsive modifications for precise delivery.

Protein/Polysaccharide-PLGA Microspheres

- Composite microspheres prepared with natural polymers such as gelatin, chitosan, and alginate.

- Enhances biocompatibility and drug stability, suitable for protein or vaccine loading.

- Pore structure and release behavior can be adjusted for sustained or rapid release.

- Supports embedding into tissue engineering scaffolds for regenerative medicine or local delivery.

Inorganic-PLGA Microspheres

- Can incorporate hydroxyapatite, silica, or magnetic nanoparticles for functional features.

- Improves mechanical strength, magnetic control, or conductivity.

- Applicable for bone repair, magnetically controlled drug delivery, and imaging diagnostics.

- Supports customized development of particle size, morphology, and composite ratios.

Drug Co-polymer/Co-loaded PLGA Microspheres

- Drugs are chemically copolymerized or physically co-loaded with PLGA to improve encapsulation efficiency.

- Enables single or multi-drug combination delivery with staged release.

- Supports hydrophobic and hydrophilic drug loading for diverse drug properties.

- Can be combined with PEGylation or targeting modifications for advanced smart delivery microspheres.

Solid Microspheres

- Uniform solid microspheres in a range of particle sizes.

- Supports efficient encapsulation of drugs or bioactive molecules.

- Controlled degradation rate for long-term sustained release.

- Customizable monodisperse or polydisperse particle distributions.

Hollow Microspheres

- Hollow microspheres with diverse pore sizes and cavity structures.

- Supports high drug or bioactive molecule loading.

- Enables rapid release or dual-stage drug release.

- Can be combined with targeting or stimuli-responsive modifications to enhance functionality.

Porous Microspheres

- Porous microspheres with adjustable internal and surface pores.

- High surface area design improves drug or protein loading efficiency.

- Pore size can be tuned to control drug release rate.

- Compatible with tissue engineering scaffolds for localized drug delivery.

Stimuli-Responsive Microspheres

- Drug release triggered by pH, temperature, or enzymatic activity.

- Supports core-shell or porous designs to enhance responsiveness.

- Can be combined with targeting modifications for intelligent delivery.

- Offers customized functional material development.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Our PLGA Microsphere Synthesis and Preparation Services

BOC Sciences provides one-stop custom services from material selection and structural design to functional modification. Whether it is structural optimization, particle size control, drug loading, or surface functionalization and stimuli-responsive design, we deliver high-precision and reliable PLGA microsphere solutions tailored to specific customer needs, supporting the development and application of biomimetic materials and advanced drug delivery systems.

1Custom PLGA Microsphere Fabrication

- Selection of PLGA materials with varying lactic acid/glycolic acid ratios according to customer requirements.

- Particle size control from nanoscale to microscale for sustained, long-acting, or targeted delivery.

- Production of solid, hollow, porous, and core-shell microsphere structures.

2Drug/Functional Molecule Loading and Optimization

- Supports loading of small molecules, proteins, peptides, vaccines, and nucleic acids.

- Provides encapsulation optimization, initial burst release control, and multi-drug delivery solutions.

- Enables copolymerization, adsorption, or physical encapsulation loading methods.

3Surface Modification and Functionalization

- PEGylation, targeting ligand conjugation, and stimuli-responsive modification.

- Improves blood circulation time, enables targeted delivery, or triggers environment-responsive drug release.

- Supports development of smart microspheres responsive to temperature, pH, or enzymatic activity.

4Particle Size and Morphology Control

- Precision control via emulsion solvent evaporation, spray drying, microfluidics, and solvent extraction/precipitation techniques.

- Customizable monodisperse or polydisperse particles to meet diverse biomimetic material application needs.

- Utilizes dynamic light scattering (DLS), scanning electron microscopy (SEM), and laser particle sizing to ensure uniform particle size and controlled morphology.

Characterization

PLGA Microsphere Analysis and Characterization Services

To ensure consistent quality, BOC Sciences provides comprehensive analysis and characterization services covering critical parameters from polymer raw materials to final microsphere products. Our expert team uses advanced instruments to measure particle size, morphology, structure, drug encapsulation efficiency, and release behavior, providing scientific data support and high-precision quality assurance for our clients.

| Test Category | Key Parameters | Testing Methods | Service Description |

|---|

| Particle Size & Distribution | Average particle size, size distribution | Dynamic Light Scattering (DLS), Laser Particle Size Analyzer, SEM | Precisely control particle size from nanometer to micrometer scale, ensuring uniformity and predictable release performance. |

| Surface Morphology | Particle shape, surface structure, porosity | Scanning Electron Microscopy (SEM), Transmission Electron Microscopy (TEM) | Analyze particle morphology, porosity, and core-shell structure to optimize preparation processes. |

| Chemical Composition | Polymer ratio, molecular weight, chemical structure | Nuclear Magnetic Resonance (NMR), Fourier Transform Infrared Spectroscopy (FTIR), Gel Permeation Chromatography (GPC) | Ensure PLGA polymer composition and molecular weight meet design specifications. |

| Drug Encapsulation | Encapsulation efficiency, drug loading | High Performance Liquid Chromatography (HPLC), UV-Vis Spectrophotometry | Accurately measure drug or active molecule loading, optimizing microsphere formulation. |

| Release Performance | Drug release profile, release rate | In vitro release study combined with HPLC/UV-Vis analysis | Simulate physiological environment to evaluate controlled or sustained release performance. |

| Thermal & Mechanical Properties | Thermal stability, glass transition temperature | Differential Scanning Calorimetry (DSC), Thermogravimetric Analysis (TGA) | Assess microsphere thermal properties and degradation behavior to support preparation and storage solutions. |

| Biocompatibility | Cell compatibility, cytotoxicity evaluation | Cell assays (MTT/Live-Dead), in vitro toxicity testing | Ensure microsphere safety and stability for biomedical applications. |

Advantages

PLGA Microsphere Service Advantages & Expertise

- Extensive Preparation Experience: With years of focus on PLGA microsphere research and development, covering the full process from laboratory-scale trials to industrial production, we have accumulated rich experience in process optimization and product development, ensuring reliable and efficient customized solutions for our clients.

- Diverse Preparation Techniques: We support emulsion-solvent evaporation, spray drying, microfluidics, and solvent extraction/precipitation methods. Processes can be flexibly selected based on particle size, morphology, and drug properties to meet different research and industrial application needs.

- High-Precision Particle Size Control: Through advanced process design and equipment control, we achieve precise particle size regulation from nanoscale to microscale, ensuring uniformity, controlled release performance, and product stability, providing assurance for high-end drug delivery applications.

- Drug Loading Optimization: Multiple drug loading methods are available, including encapsulation, adsorption, and copolymerization. Combined with release curve optimization techniques, we effectively control initial burst release and realize controlled drug release solutions ranging from short- to long-acting formulations.

- Functional Microsphere Development: We support PEGylation, targeting modifications, and environment-responsive functionalization to develop smart microspheres, achieving targeted delivery to specific tissues or cells and pH/temperature/enzyme-triggered release, fulfilling the needs of advanced biomimetic materials and drug delivery applications.

- Comprehensive Analysis and Quality Assurance System: Equipped with HPLC, FTIR, NMR, SEM, DLS, and other analytical instruments, we perform comprehensive evaluation of particle size, morphology, drug encapsulation, and release behavior, ensuring each batch meets strict quality standards.

- One-Stop Service: We provide end-to-end services from raw material selection, formulation development, microsphere preparation, functional modification to performance characterization, offering full technical support for research and industrial applications and accelerating product development timelines.

Service Process

PLGA Microsphere Manufacturing Workflow & Custom Service Process

To ensure high-quality and reliable PLGA microsphere preparation, BOC Sciences provides a systematic, fully controlled service workflow. From customer requirement analysis to microsphere fabrication, functional modification, and performance verification, we apply professional expertise and advanced equipment at every step to guarantee that the final products meet the diverse needs of research and industrial applications.

1Requirement Analysis and Technical Evaluation

- In-depth understanding of the client's application goals, drug or active molecule type, particle size, and release requirements.

- Feasibility assessment and technical recommendations to develop a personalized preparation plan.

2Raw Material Selection and Formulation Design

- Selecting appropriate PLGA types, lactic acid/glycolic acid ratios, and molecular weights based on client needs.

- Designing microsphere structures (solid, hollow, porous, core-shell) and functional modification strategies.

3Microsphere Preparation and Process Optimization

- Applying emulsion-solvent evaporation, spray drying, microfluidics, and other fabrication methods.

- Controlling particle size, morphology, porosity, and encapsulation efficiency to achieve targeted release profiles.

4Drug or Active Molecule Loading

- Supports encapsulation, adsorption, copolymerization, and other loading methods.

- Optimizes loading efficiency and initial burst release to ensure long-term stable release performance.

5Functional Modification and Surface Engineering

- Provides PEGylation, targeted ligand conjugation, and environment-responsive modification.

- Meets high-end applications such as targeted delivery, prolonged circulation, or smart release.

6Performance Characterization and Quality Control

- Utilizes DLS, SEM, HPLC, FTIR, NMR, and other instruments to evaluate particle size, morphology, chemical composition, and drug release profiles.

- Provides comprehensive test reports to ensure microsphere performance meets design specifications and client standards.

Applications

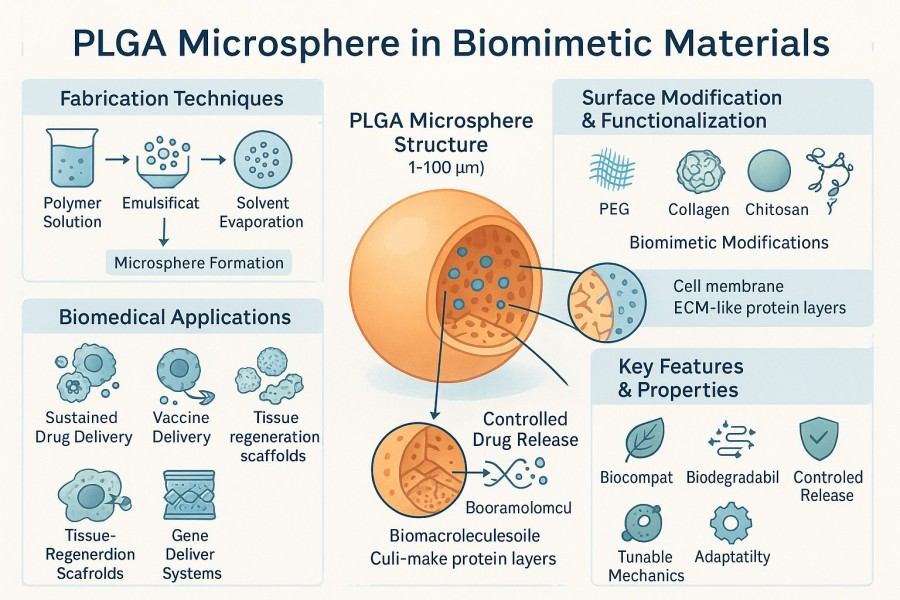

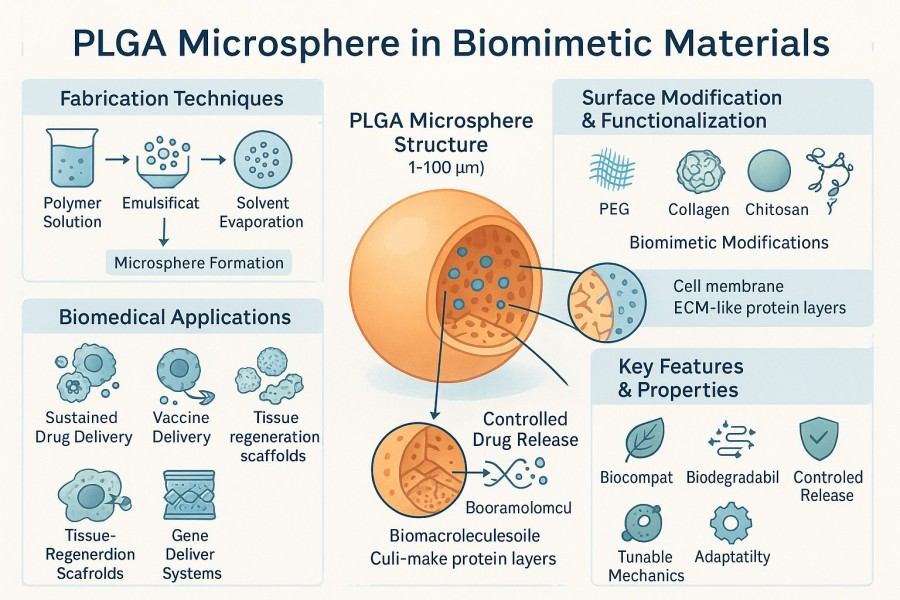

Applications of PLGA Microspheres in Biomimetic Materials

With controllable degradability, biocompatibility, and versatile functionalization, PLGA microspheres hold broad application value in biomimetic materials. By precisely regulating microsphere structure, particle size, and loading of drugs or bioactive molecules, they can mimic natural tissue environments, enabling drug delivery, tissue repair, and functional material development. BOC Sciences leverages advanced fabrication and analytical techniques to provide full technical support and customized solutions for biomimetic material R&D.

Drug Delivery and Controlled Release Systems

- PLGA microspheres enable sustained, long-acting, or localized drug release.

- Supports precise loading of small molecules, proteins, peptides, and nucleic acids.

- Release rates can be adjusted via particle size, structure, and material modification to meet different therapeutic requirements.

- Applicable for local drug delivery, tumor targeting, and chronic disease management.

Tissue Engineering and Regenerative Medicine

- Microspheres can serve as cell scaffolds or filler materials, simulating natural extracellular matrix (ECM) structures.

- Porous or core-shell structures promote cell adhesion, growth, and differentiation.

- Can be combined with growth factors or signaling molecules for tissue regeneration and functional repair.

- Supports the development of bone, soft tissue, and vascular scaffolds.

Functional Biomimetic Material Development

- PLGA microspheres can be combined with proteins, polysaccharides, or inorganic materials to enhance bioactivity and mechanical properties.

- Environment-responsive microspheres can be developed for smart release or targeting functionality.

- Applicable for creating biomimetic drug carriers, intelligent biomimetic membranes, or injectable scaffolds.

- Supports customized functional development for research and industrial applications.

Vaccine and Bioactive Molecule Carriers

- Microspheres can act as antigen delivery carriers to enhance immune responses.

- Supports stable loading of proteins, nucleic acids, and peptides.

- Release profiles can be tuned to provide initial immune stimulation and long-term antibody maintenance.

- Significant potential in novel vaccine and biopharmaceutical development.

FAQs

Frequently Asked Questions

-

What are PLGA microspheres?

PLGA microspheres are biodegradable and biocompatible polymer particles made from poly(lactic-co-glycolic acid) (PLGA). They are widely used in drug delivery, tissue engineering, and biomaterials due to their controlled degradation, tunable drug release profiles, and versatility in loading small molecules, proteins, peptides, nucleic acids, or vaccines. PLGA microspheres can be engineered in various structures—solid, hollow, porous, or core-shell—to meet specific therapeutic or research requirements.

-

How to make PLGA microspheres?

PLGA microspheres are typically prepared using techniques such as emulsion-solvent evaporation, solvent extraction/precipitation, spray drying, or microfluidics. The process involves dissolving PLGA in an organic solvent, dispersing it in an aqueous phase with stabilizers to form droplets, and then solidifying the droplets into microspheres by solvent removal. Parameters such as PLGA composition, molecular weight, droplet size, and stirring rate are controlled to adjust particle size, morphology, drug loading, and release kinetics. Functionalization, such as PEGylation or ligand conjugation, can be applied to enhance targeting or responsive release.

-

What types of drugs can PLGA microspheres carry?

PLGA microspheres are suitable for a wide range of drugs, including small molecules, peptides, proteins, vaccines, and nucleic acids. Through encapsulation, adsorption, or copolymerization, they effectively protect drug stability while enabling controlled initial release and long-term sustained delivery. Microsphere structure and material modification can be optimized to meet the release requirements of different drug properties, serving research, drug delivery, and biomimetic material development.

-

How is microsphere particle size controlled?

BOC Sciences achieves precise particle size control from nanoscale to microscale (50 nm–1000 μm) through sophisticated process design. Emulsion ratios, stirring speed, solvent type, and microfluidics parameters are adjusted to achieve monodisperse or polydisperse distributions. Particle size directly affects drug release rate, in vivo distribution, and cellular uptake efficiency, ensuring consistent performance for research and industrial applications.

-

How is controlled drug release achieved?

Controlled release from PLGA microspheres is achieved by adjusting lactic acid/glycolic acid ratios, PLGA molecular weight, microsphere structure (solid, hollow, porous, or core-shell), and surface functionalization. Different combinations allow drug release from days to months, meeting short- and long-term therapeutic needs. Scientific design enables precise control of initial burst release while maintaining long-term stability, providing reliable solutions for drug delivery and biomimetic applications.

-

Are targeted or stimuli-responsive microspheres supported?

Yes. BOC Sciences can develop PEGylated, targeted ligand-conjugated, or environment-responsive PLGA microspheres according to client requirements. Microspheres can release drugs in response to pH, temperature, or enzymatic activity, enhancing efficacy while reducing side effects. Combined with particle size control and functional modification, they can deliver drugs to tumors, specific organs, or cells, and support smart biomimetic material development for advanced research and preclinical studies.

-

What is the BOC Sciences service workflow?

Our PLGA microsphere service workflow covers the entire process from requirement analysis, formulation design, process development, microsphere preparation, functional modification, to performance characterization and delivery. Each step can be customized based on project-specific goals, including particle size, structure, drug loading, and release optimization, ensuring microsphere products meet research and industrial standards, accelerate development timelines, improve R&D efficiency, and provide reliable customized solutions.