Polyvinyl Alcohol (PVA) Services

Browse by

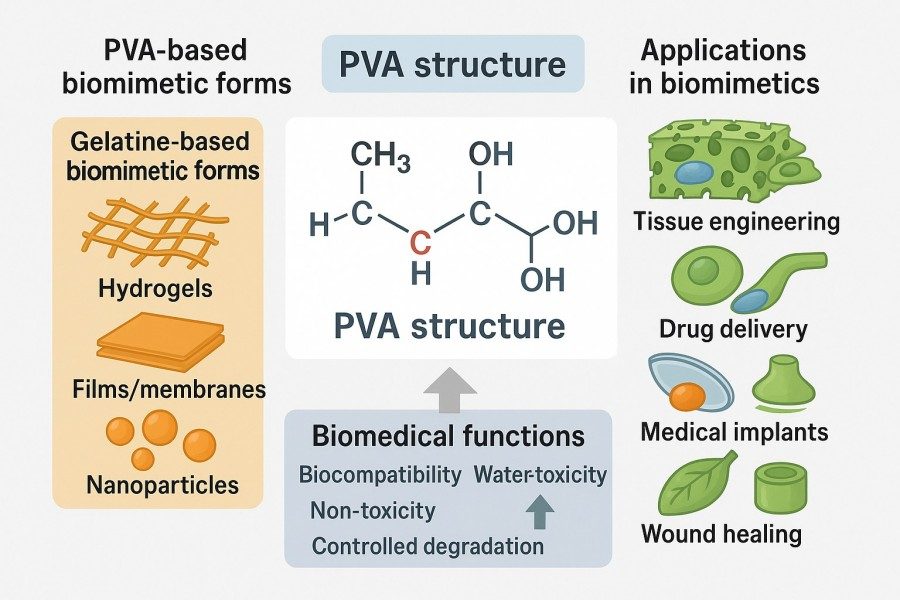

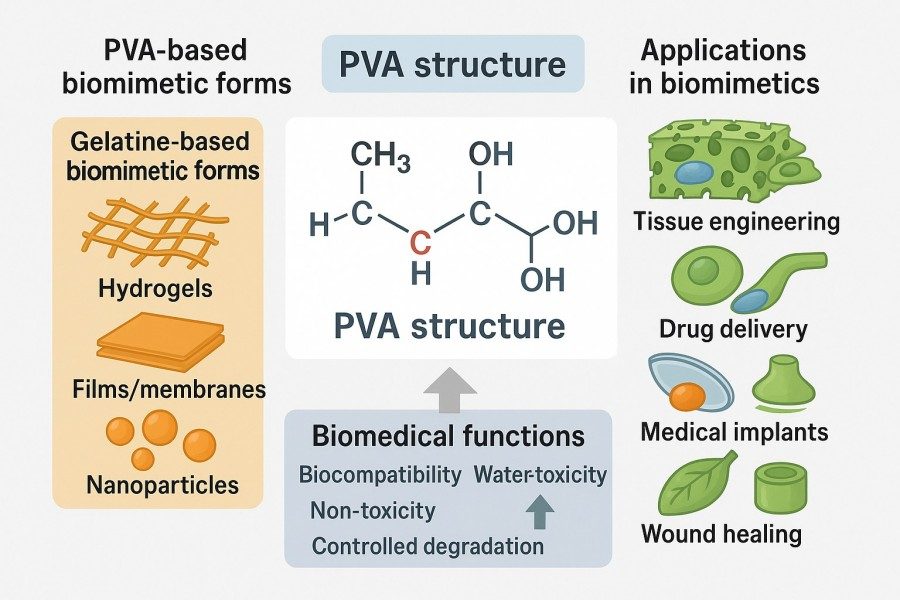

Polyvinyl alcohol (PVA) is a water-soluble polymer that has become a key material in the field of biomimetic materials due to its excellent water solubility, film-forming ability, mechanical strength, and biocompatibility. Whether applied in hydrogels, films, fiber scaffolds, micro/nanostructures, or drug delivery carriers, PVA demonstrates high scientific and industrial value. BOC Sciences provides comprehensive support through professional custom synthesis, functional modification, analytical characterization, and process optimization services, assisting researchers, developers, and manufacturers in developing, optimizing, and scaling novel biomimetic materials. From hydrogels and films to fiber scaffolds, microstructures, and microcapsules, BOC Sciences delivers efficient, reliable, and customizable solutions to support both research and industrialization.

What We Offer

Polyvinyl Alcohol Support for Biomimetic Materials

BOC Sciences offers PVA raw materials with controllable molecular weight, hydrolysis degree, and crystallinity, and can also develop various PVA forms to meet diverse research and industrial needs. Our team can design and prepare multiple PVA formats, including hydrogels, films, microspheres, fibers, and composites, tailored to clients' specific goals. This ensures optimal structural stability, functional tunability, and application versatility. With such diversified support, BOC Sciences helps clients shorten R&D timelines from concept to application and provides strong backing for innovations in medical, pharmaceutical, tissue repair, biodegradable packaging, and advanced functional materials.

- Highly water-absorbent with excellent biocompatibility, capable of mimicking the extracellular matrix (ECM).

- Applied in tissue engineering scaffolds, drug delivery systems, and wound healing materials.

- Available with multiple crosslinking methods and functional modification options.

- Outstanding film-forming ability, transparency, and mechanical strength.

- Used in drug packaging, biodegradable carriers, flexible sensors, and wearable devices.

- Supports customization of thickness, crystallinity, and surface properties.

- Excellent film-forming and adhesive properties with high transparency.

- Used for surface modification of biomedical devices, drug coatings, and antibacterial protective layers.

- Functionalized treatments enhance durability and biocompatibility.

- Controlled particle size, uniform structure, and good dispersibility.

- Applied in drug delivery, protein/nucleic acid immobilization, and controlled-release platforms.

- Supports multiple surface functionalizations (e.g., carboxylation, amination).

Polyvinyl Alcohol Scaffolds

- Porous structures constructed via freeze-drying, 3D printing, or electrospinning.

- Provides a microenvironment close to natural tissues, supporting cell proliferation and differentiation.

- Widely used in tissue engineering, regenerative medicine, and biomimetic repair materials.

- High strength and flexibility, can be fabricated into nano- or microfibers via electrospinning.

- Forms three-dimensional porous networks that promote cell adhesion and migration.

- Applied in tissue repair scaffolds, biodegradable filters, and medical dressings.

Polyvinyl Alcohol Composites

- Combined with inorganic nanoparticles, natural polymers, or synthetic polymers.

- Enhances mechanical performance, thermal stability, and functional diversity.

- Used in bone repair materials, high-performance sensors, and conductive films.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Polyvinyl Alcohol Custom Solutions for Biomimetic Applications

In the development and application of biomimetic materials, the performance control and processing methods of PVA directly determine the structure, functionality, and application value of the final material. To help researchers, developers, and manufacturers achieve their innovation goals more efficiently, BOC Sciences has established a comprehensive PVA service system covering custom synthesis, functional optimization, performance analysis, and application support. We can flexibly design PVA products with different molecular weights, hydrolysis degrees, and functionalities, and provide professional characterization, process development, and technology transfer services to ensure stability and reliability in both laboratory research and industrial production.

1Custom PVA Synthesis

- Design and produce PVA materials with specific molecular weights, hydrolysis degrees, and polymerization levels according to client requirements.

- Supports small, pilot, and large-scale production of high-purity PVA for research, process development, and industrial applications.

- Offers various solubility and viscosity specifications to suit different biomimetic material processing techniques.

2PVA Functional Modification Services

- Provides physical and chemical modification options such as crosslinking, graft copolymerization, and surface functionalization to enhance mechanical properties, stability, and functionality.

- Enables the preparation of controllable hydrogels, elastic films, conductive membranes, or bioactive scaffolds tailored to application needs.

- Supports composite modifications, combining natural polymers (gelatin, alginate) or nanoparticles (graphene oxide, hydroxyapatite) to create multifunctional materials.

3Analysis and Characterization Services

- Offers molecular weight, polymerization degree, hydrolysis degree, and molecular structure analysis of PVA.

- Tests mechanical properties of films, fibers, and hydrogels, including tensile strength, elastic modulus, and elongation at break.

- Evaluates thermal properties, crystallinity, and solubility characteristics to support material formulation optimization and process validation.

4Process Development and Technology Transfer

- Provides tailored PVA formulations and functionalization strategies for different researchers and developers.

- Supports pilot and large-scale process scaling to ensure consistent material performance.

- Offers guidance on material storage, dissolution, and processing to guarantee stability in applications.

Advantages

PVA Service Excellence Customization Quality Performance

- High Customization Capability: PVA molecular weight, hydrolysis degree, and functional groups can be flexibly adjusted according to clients' specific requirements, enabling personalized design from structure to performance to meet diverse biomimetic applications.

- Professional Technical Team: Our team consists of experienced polymer chemistry and biomimetic materials experts with extensive project experience and R&D capabilities, providing full-process technical consultation and implementation support.

- Comprehensive Full-Process Services: Services cover material design, custom synthesis, functional optimization, analytical characterization, process development, and scale-up production, delivering efficient, one-stop solutions for clients.

- Composite and Functionalization Capability: We develop multifunctional PVA materials combined with natural polymers, inorganic nanoparticles, or active molecules to enhance mechanical performance, biocompatibility, and functional diversity.

- Rapid Sample and Bulk Production: Supports small-batch rapid prototyping, pilot scale, and industrial-scale production, helping clients shorten R&D cycles and efficiently transition from lab to market.

- Strict Quality Control: Leveraging advanced analytical instruments and performance testing platforms, we ensure consistency, purity, and functional performance, guaranteeing reliability and stability of the final product.

Service Process

Client Support and Service Workflow

To meet the diverse needs of biomimetic material researchers and developers, BOC Sciences has established a systematic, standardized service workflow. We focus not only on material performance and quality but also on R&D efficiency, application adaptability, and industrial feasibility. From requirements analysis and design optimization to custom synthesis and process transfer, we provide full-process support, ensuring that each stage progresses efficiently, accurately, and controllably, enabling a seamless transition from research exploration to practical application.

1Requirements Communication

At the project initiation stage, we engage in in-depth discussions with clients to fully understand their R&D objectives or industrial goals, clarifying key requirements such as PVA molecular weight, hydrolysis degree, purity, and mechanical properties. Precise information gathering ensures that subsequent service plans are closely aligned with clients' application scenarios and expectations.

2Material Design

Based on clients' specific application needs, we provide scientifically sound PVA design solutions, including selection of molecular weight ranges, hydrolysis degree control, and processing method recommendations. We also consider the characteristics of the application field (e.g., tissue engineering, drug delivery, coating materials) to recommend optimal parameter combinations, helping clients reduce trial-and-error costs in experiments and product development.

3Custom Synthesis

With flexible production capabilities, we adjust synthesis processes and formulations at small, pilot, and industrial scales according to client requirements. Rigorous process control and formulation optimization ensure that PVA products meet specific performance, stability, and consistency requirements, providing a reliable foundation for further research and application.

4Functional Modification

To meet the specialized functional requirements of biomimetic materials, we offer diverse modification strategies, including physical crosslinking, chemical modification, and composites with nanoparticles or natural polymers. Functionalization can effectively enhance mechanical strength, water stability, biocompatibility, or other specific properties, expanding PVA's potential across various applications.

5Analysis and Characterization

Equipped with a complete testing and analysis platform, we provide comprehensive characterization of PVA materials, including molecular structure confirmation, thermal analysis, mechanical property testing, solubility, and biocompatibility evaluation. Systematic characterization ensures product quality and provides reliable scientific support for optimizing material performance and understanding material behavior.

6Technical Support and Process Transfer

During the critical transition from lab research to industrial application, we provide full-scale process optimization and technical guidance, including scale-up validation, parameter optimization, and batch stability evaluation. Through strict process control and accumulated experience, we ensure clients can smoothly transition from R&D to large-scale production while maintaining consistent and reproducible material performance.

Applications

Applications of Polyvinyl Alcohol in Biomimetic Materials

PVA's excellent water solubility, biocompatibility, film-forming ability, and ease of processing make it a promising material in biomimetic research and applications. It can mimic the structure and function of natural biological systems and achieve higher performance through modification or composite formation, making it a critical base material for novel biomimetic constructs. BOC Sciences provides customized PVA products and solutions to help researchers and developers innovate across multiple cutting-edge fields.

Tissue Engineering and Regenerative Medicine

PVA can be processed into hydrogels, fibers, or 3D scaffolds through freeze-thaw cycles, crosslinking, or electrospinning, providing cells with a growth environment similar to the extracellular matrix. Its tunable porosity and mechanical properties make it suitable for cartilage repair, bone tissue replacement, and nerve conduit construction. BOC Sciences designs customized PVA scaffolds and hydrogel solutions to meet the specific requirements of tissue engineering research.

Drug Delivery and Controlled Release Systems

PVA's excellent swelling properties and crosslinkability enable controlled drug release. By preparing microspheres, films, or hydrogels, drug release rates can be effectively regulated, improving stability and bioavailability. This makes PVA ideal for oral sustained-release formulations, implantable carriers, and localized delivery systems. BOC Sciences provides particle-size-controlled and functionally tunable PVA delivery carriers to support end-to-end drug development.

Biomedical Devices and Coatings

PVA films and coatings offer transparency, flexibility, and strong adhesion, applicable to medical sensors, intraocular lenses, anti-adhesion membranes, and surgical instrument surfaces. Functional modifications can further enhance antibacterial properties and durability, improving safety in use. BOC Sciences provides comprehensive services from film preparation to surface functionalization, supporting innovation in medical devices and related products.

Flexible Electronics and Biomimetic Sensors

PVA's processability and mechanical performance make it an ideal substrate and functional composite material. Its films and composites are applied in wearable devices, flexible displays, and environmental sensors, providing high transparency and mechanical stability. Combined with conductive materials or nanofillers, multifunctional integration is achievable. BOC Sciences offers diverse PVA material formats to support the development of biomimetic electronics.

FAQs

Frequently Asked Questions

-

What is polyvinyl alcohol?

Polyvinyl alcohol (PVA) is a water-soluble synthetic polymer widely used in biomedical, industrial, and packaging applications. It is known for its excellent film-forming ability, adhesive properties, chemical resistance, and biocompatibility. PVA can be tailored with different molecular weights and degrees of hydrolysis, making it suitable for hydrogels, coatings, fibers, and composite materials in research and industrial production.

-

Is polyvinyl alcohol polar or nonpolar?

Polyvinyl alcohol (PVA) is a highly polar polymer due to its abundant hydroxyl (-OH) groups along the backbone. These polar groups provide strong hydrogen bonding, water solubility, and compatibility with other hydrophilic materials. The polarity of PVA enables it to form hydrogels, films, and composite materials that interact effectively with aqueous environments, cells, and biomolecules in biomedical and industrial applications.

-

What is polyvinyl alcohol used for?

Polyvinyl alcohol (PVA) is widely used in biomedical applications, tissue engineering, drug delivery systems, and wound dressings. It is also employed in adhesives, paper coatings, packaging films, textile sizing, and flexible electronics. PVA's water solubility, film-forming ability, and mechanical stability make it an ideal material for hydrogels, fibers, coatings, and composite materials in both laboratory research and industrial manufacturing.

-

Is PVA a hydrogel?

Yes, PVA can form hydrogels through physical crosslinking, chemical crosslinking, or freeze-thaw cycles. PVA hydrogels are highly hydrated, biocompatible, and mechanically tunable, making them ideal for tissue engineering scaffolds, drug delivery systems, and soft biomedical devices. Their porous structure and water retention capabilities enable controlled release of bioactive molecules and mimicry of extracellular matrix environments.

-

Is PVA biocompatible?

Yes, polyvinyl alcohol (PVA) is biocompatible, non-toxic, and widely used in medical and pharmaceutical applications. Its excellent compatibility with cells and tissues allows safe use in hydrogels, scaffolds, wound dressings, and drug delivery systems. Biocompatible PVA materials are also suitable for research in tissue engineering, regenerative medicine, and biodegradable packaging, offering reliable performance in both in vitro and in vivo studies.

-

How is polyvinyl alcohol produced?

Polyvinyl alcohol (PVA) is produced through the hydrolysis or alcoholysis of polyvinyl acetate (PVAc). Polyvinyl acetate is first synthesized via polymerization of vinyl acetate monomers, then partially or fully hydrolyzed using water or alcohol in the presence of catalysts. This process controls the degree of hydrolysis, molecular weight, and crystallinity, allowing customization of PVA properties for hydrogels, films, fibers, coatings, and composite applications.

Polyvinyl Alcohol Coating Preparation

Polyvinyl Alcohol Coating Preparation

Polyvinyl Alcohol Film Preparation

Polyvinyl Alcohol Film Preparation

Polyvinyl Alcohol Hydrogel Preparation

Polyvinyl Alcohol Hydrogel Preparation

Polyvinyl Alcohol Fiber Preparation

Polyvinyl Alcohol Fiber Preparation

Polyvinyl Alcohol Microsphere Preparation

Polyvinyl Alcohol Microsphere Preparation