Polymer Micelle Synthesis

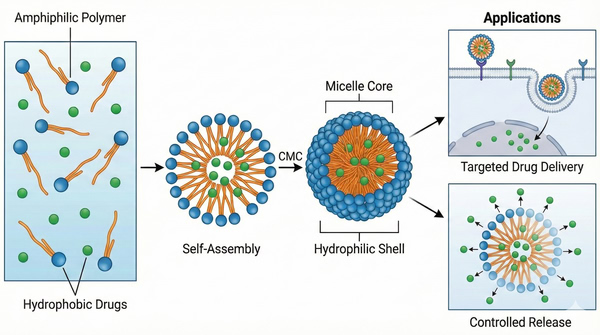

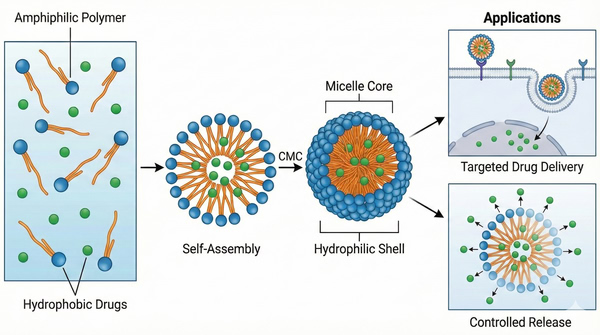

Polymer micelles are a class of nanoscale structures formed by the self-assembly of amphiphilic or block copolymers. They typically adopt a core–shell structure in aqueous solutions, where the hydrophobic blocks aggregate to form the micelle core, while the hydrophilic blocks extend outward to form the micelle shell, enabling nanoscale stability. Compared with micelles formed from conventional small-molecule surfactants, polymer micelles offer higher stability, more controllable sizes, and tunable functional properties. Their diameters generally range from 10–100 nm, with controllable sizes and diverse morphologies (spherical, rod-like, or vesicular), which can be precisely designed by adjusting block ratios, molecular weight, and solution conditions. This unique architecture provides significant applications in drug delivery, gene carriers, imaging diagnostics, and functional materials. BOC Sciences offers highly controllable, high-purity polymer micelle synthesis services. We provide full-process customization, from molecular design and block selection to functional modification, ensuring micelles meet diverse research and development requirements in terms of size, morphology, drug-loading capacity, and surface functionality. Whether for drug delivery, gene transfer, or multifunctional applications, we deliver professional guidance and high-quality products to help clients achieve project success.

Services

Explore the Polymer Micelle Types Available for Your Research

Leveraging extensive polymer synthesis experience and advanced self-assembly technologies, BOC Sciences provides a variety of polymer micelle types to meet different research and development needs. From molecular design and functional modification to size and morphology control, we deliver highly controllable, high-purity polymer micelle products. Our main categories include:

-

By Polymer Type

-

Block Copolymer Micelles: Formed from two or more different polymer segments, e.g., PEG-b-PLA (polyethylene glycol–polylactic acid) and PEG-b-PCL (polyethylene glycol–polycaprolactone).

-

Functionalized Block Copolymer Micelles: Surface-modified with targeting ligands or responsive functional groups for targeted delivery or controlled release.

-

By Functional Features

-

Drug-Carrier Micelles: Designed for solubilization and delivery of hydrophobic drugs.

-

Stimuli-Responsive Micelles: Sensitive to pH, temperature, light, enzymes, or reducing environments, enabling controlled release.

-

Targeted Micelles: Surface-functionalized with antibodies, peptides, or small molecules for tumor or tissue-specific delivery.

-

By Morphology

-

Spherical Micelles: Most common, with diameters of 10–100 nm.

-

Rod-like Micelles: Extend blood circulation time, suitable for long-acting drug delivery.

-

Vesicular or Aggregated Micelles: Form larger hollow structures for high-capacity drug loading.

-

Customization Capabilities

-

Polymer micelles with varying molecular weights and block ratios.

-

Surface functionalization (e.g., targeting ligands, fluorescent labels, responsive groups).

-

Encapsulation of specific drugs, dyes, or biomolecules.

Looking for Custom Polymer Micelles?

From drug delivery to gene therapy and imaging, BOC Sciences provides high-purity, fully customizable polymer micelles to advance your research and development.

Technology

High-Precision Polymer Micelle Technology by BOC Sciences

BOC Sciences provides highly controllable, high-purity polymer micelle synthesis services. We focus on full-process support, from molecular design to functional modification, ensuring each batch meets strict standards in size, morphology, drug-loading capacity, and functionalization.

1Highly Controllable Block Copolymer Synthesis

-

Precisely tune polymer molecular weight, block ratio, and hydrophobic/hydrophilic balance for controlled micelle size and stability.

-

Support multiple block copolymer systems, including PEG-b-PLA, PEG-b-PCL, and functionalized polymers.

-

Offer degradable and stimuli-responsive polymer designs to meet diverse drug delivery and research requirements.

-

Strict process monitoring ensures high batch-to-batch consistency and reproducibility.

2Precision Micelle Self-Assembly

-

Utilize aqueous self-assembly, solvent displacement, and microfluidic methods to achieve precise nanoscale core–shell control.

-

Adjust micelle diameter, PDI, and shell thickness to optimize drug-loading efficiency and release performance.

-

Support customization of spherical, rod-like, and vesicular micelles.

-

Provide complete self-assembly design and technical guidance to ensure stable, application-ready micelles.

3Drug and Functional Molecule Encapsulation

-

Efficiently encapsulate hydrophobic drugs, nucleic acids, and functional molecules, enhancing solubility and bioavailability.

-

Enable targeted delivery or stimuli-responsive controlled release to improve therapeutic efficacy and experimental control.

-

Offer optimization strategies to maximize drug-loading and stability.

-

Combine with surface functionalization for multifunctional micelle development, including targeting and imaging labeling.

4Surface Functionalization and Custom Modifications

-

Support modification with antibodies, peptides, small molecules, and responsive groups to enhance targeting and in vivo stability.

-

Design multifunctional micelles for theranostic integration or smart drug release.

-

Offer custom solutions for specific microenvironment responses (pH, enzymes, reducing conditions).

-

Provide full technical support and characterization services to ensure functionalized micelles are stable and reproducible.

Characterization

Polymer Micelle Quality Management System

Leveraging years of experience in polymer synthesis and rigorous research standards, BOC Sciences has established a comprehensive quality management system for polymer micelles. Through systematic characterization and testing, we ensure that every batch of polymer micelles meets high standards in size, morphology, drug-loading capacity, and functionalization. Our system covers the full production chain—from raw materials to final product—ensuring high purity, stability, and reproducibility.

|

Test Item

|

Purpose

|

Instrument/Method

|

Description

|

|

Particle Size and Distribution

|

Control micelle size and uniformity, influencing in vivo distribution and drug release

|

Dynamic Light Scattering (DLS)

|

Precisely measures average size and polydispersity index (PDI) to ensure micelle dimensions meet design specifications and evaluate stability.

|

|

Core-Shell Structure Verification

|

Confirm formation and integrity of micelle core-shell structure

|

TEM / SEM

|

High-resolution imaging of micelle core and shell to identify spherical, rod-like, or vesicular structures and assess self-assembly quality.

|

|

Polymer Molecular Weight and Block Ratio

|

Ensure accurate block copolymer design, affecting micelle stability and functionality

|

NMR, GPC

|

Measures polymer molecular weight and distribution; analyzes hydrophilic/hydrophobic block ratio for controlled synthesis and reproducibility.

|

|

Drug/Functional Molecule Loading

|

Evaluate loading efficiency, release performance, and stability

|

HPLC, UV-Vis

|

Quantifies drug or functional molecule loading to ensure high core encapsulation efficiency and controlled release.

|

|

Surface Functionalization Verification

|

Confirm successful targeting or stimuli-responsive modification

|

Fluorescence Spectroscopy, MS, XPS

|

Detects presence and density of functional groups; verifies targeting ligands, responsive groups, or fluorescent tags.

|

|

Stability Testing

|

Assess long-term stability under in vitro and storage conditions

|

DLS, Zeta Potential, Centrifugation

|

Measures size changes, aggregation, and surface charge stability to ensure structural integrity under various conditions.

|

|

Solution Clarity and Turbidity

|

Ensure uniform micelle solution without precipitation or insoluble particles

|

UV-Vis Spectrophotometer

|

Detects dispersion state and homogeneity of the micelle solution to guarantee readiness for experimental or application use.

|

|

pH and Ionic Strength Compatibility

|

Ensure micelle stability under different physiological conditions

|

pH Meter, Ion Meter

|

Tests micelle stability under varying pH and ionic conditions to simulate in vivo environments and enhance reliability.

|

|

Lyophilization and Reconstitution

|

Verify performance after freeze-drying and rehydration

|

Freeze Dryer, DLS, TEM

|

Ensures micelles can be stably freeze-dried and, upon rehydration, maintain size, morphology, and drug-loading performance, facilitating storage and transport.

|

Advantages

High-Precision Solutions and Expert Support You Can Rely On

-

High-Precision Synthesis Capability: Control polymer molecular weight from 2–100 kDa, with hydrophobic/hydrophilic block ratio accuracy up to ±5%, ensuring controllable micelle size, morphology, and stability.

-

Advanced Self-Assembly Technology: Support micelle sizes of 10–200 nm, with spherical, rod-like, and vesicular structures. Response times can be precisely tuned from 1–24 hours, enabling accurate drug loading and controlled release.

-

Comprehensive Functionalization Services: Offer more than five surface modification options (targeting, fluorescent, responsive, etc.), enabling multifunctional micelle design to meet both preclinical and basic research needs.

-

Strict Quality Management System: Over 10 key characterization parameters (particle size, PDI, drug-loading, functional verification, etc.) ensure each batch is high-purity, reproducible, and stable.

-

Professional Technical Team Support: Experienced biochemistry and polymer chemistry experts provide full technical guidance, experimental protocol optimization, and problem-solving to ensure smooth project progress.

-

Advanced Laboratory Facilities: Equipped with more than 10 high-end instruments, including DLS, TEM/SEM, NMR, GPC, and HPLC, for precise characterization, functional verification, and batch consistency control.

-

Customization and Rapid Response: Provide diverse custom services, including design of micelle size, functionalization, drug-loading capacity, and responsive mechanisms, responding efficiently to client research and development needs.

Service Process

How We Deliver Your Polymer Micelle Project?

At BOC Sciences, we provide full-process custom polymer micelle services, from requirement analysis to final delivery. By combining standardized procedures with flexible customization, we ensure each project progresses efficiently to meet the diverse demands of research, drug development, and industrial applications. A typical service workflow includes:

1Project Requirement Assessment

We work closely with clients to gather research objectives, drug characteristics, and functionalization needs. Our team provides feasibility analysis, technical route recommendations, and expected outcome evaluation, ensuring projects are controllable and precise from the design stage.

2Molecular Design and Plan Development

Based on client requirements, we design block copolymer structures, micelle sizes, and functionalization schemes. Multiple design options are provided, including core/shell ratios, responsive modifications, and targeting ligands, along with detailed technical plans and experimental protocols.

3Polymer Synthesis and Preliminary Characterization

Target block copolymers are synthesized using high-precision polymerization techniques, with characterization of molecular weight, degree of polymerization, and block ratios. This ensures controlled raw material quality, providing a reliable foundation for subsequent micelle self-assembly and functionalization.

4Micelle Self-Assembly and Functionalization

Micelles are formed via aqueous self-assembly, solvent displacement, or microfluidic methods, followed by surface modification as required (targeting ligands, responsive groups, or fluorescent labels). Size, morphology, and core–shell structure are strictly controlled to ensure stable performance.

5Characterization and Quality Control

Comprehensive characterization is performed, including particle size distribution, PDI, core–shell structure, drug-loading, and functional verification. Techniques such as DLS, TEM, HPLC, and NMR are applied to ensure each batch meets high-purity, reproducible, and stable standards.

6Delivery and Technical Support

Micelle formulations are delivered in the desired forms (solution, lyophilized powder, etc.) along with complete characterization reports. We provide operational guidance and technical consultation to support clients’ subsequent research, experiments, or preclinical applications, ensuring successful project implementation.

Applications

Unlock the Potential of Polymer Micelles for Your Projects

BOC Sciences' polymer micelle synthesis services are widely applied across multiple research and development fields. Leveraging extensive synthesis experience, precise self-assembly technology, and comprehensive functionalization capabilities, we provide highly controllable, high-performance micelle materials for various research scenarios.

Drug Delivery

-

Enhance solubility of hydrophobic drugs for improved water solubility and efficient absorption.

-

Prolong blood circulation time, reduce immune clearance, and improve in vivo drug stability.

-

Enable targeted delivery to tumors or specific organs through surface modification.

-

Achieve controlled drug release to optimize therapeutic windows, reduce side effects, and improve efficacy.

-

Support a wide range of drugs, including small molecules, proteins, and peptides.

Gene and Nucleic Acid Delivery

-

Efficiently encapsulate siRNA, mRNA, or DNA to improve in vivo stability.

-

Enhance transfection efficiency and cellular uptake through targeted or environment-responsive design.

-

Provide customized nucleic acid delivery solutions, including size, loading capacity, and release mechanisms.

-

Combine with additional functionalization for controlled release and multifunctional applications.

-

Serve as a reliable platform for gene therapy, vaccine development, and basic research.

Imaging and Diagnostics

-

Serve as efficient carriers for fluorescent, MRI, or CT imaging agents, enhancing signal strength.

-

Achieve precise lesion or tissue targeting through surface modification.

-

Enable theranostic platforms integrating both imaging and therapeutic functions.

-

Support multimodal imaging systems to improve research and preclinical diagnostic accuracy.

-

Provide stable and reproducible micelle carriers to ensure imaging agent activity and biocompatibility.

Functional Materials

-

Serve as nanocatalyst carriers for efficient and reusable catalytic reactions.

-

Enable adsorption and removal of environmental pollutants, including heavy metals, dyes, or organic contaminants.

-

Deliver and protect active ingredients in cosmetics, improving skin penetration and stability.

-

Support studies on nanostructure design and self-assembly mechanisms for materials science and fundamental research.

-

Combine with responsive groups to develop smart functional materials.

FAQs

Frequently Asked Questions

-

What is a polymer micelle?

A polymer micelle is a nanoscale assembly formed by amphiphilic block copolymers in aqueous solutions. The hydrophobic segments form a core that can encapsulate poorly soluble drugs, while the hydrophilic segments form a protective shell, enhancing solubility and stability. Polymer micelles are widely used in drug delivery, functional materials, nucleic acid transport, and imaging applications due to their tunable size, morphology, and surface functionality.

-

What is the difference between polymeric micelles and micelles?

Traditional micelles are formed by small-molecule surfactants, whereas polymeric micelles are self-assembled from amphiphilic block copolymers. Polymeric micelles have larger size, better structural stability, higher drug-loading capacity, and prolonged circulation time in vivo. They also allow surface modification for targeting or stimuli-responsiveness, making them more suitable for controlled drug delivery and multifunctional biomedical applications.

-

What are the advantages of polymeric micelles?

Polymeric micelles improve solubility of hydrophobic drugs, enable controlled and sustained release, and reduce systemic toxicity. They can be surface-functionalized for targeted delivery, respond to environmental stimuli like pH or temperature, and enhance circulation stability. Additionally, their size, morphology, and composition are highly tunable, supporting multifunctional designs for drug delivery, imaging, or theranostic applications.

-

How to make polymeric micelles?

Polymeric micelles are typically prepared by self-assembly of amphiphilic block copolymers in water. Methods include solvent evaporation, solvent displacement, dialysis, or microfluidics. Hydrophobic drugs or functional molecules are incorporated into the micelle core during assembly. Subsequent characterization ensures the desired size, polydispersity, morphology, and drug-loading efficiency are achieved for stable and reproducible micelles.

-

What types of polymer micelles can you provide?

BOC Sciences offers a wide range of polymer micelles, including block copolymer micelles, functionalized micelles with targeting ligands, stimuli-responsive micelles, and various morphologies such as spherical, rod-like, and vesicular. We can customize polymer composition, molecular weight, size, and surface modification to meet specific research or drug delivery requirements.

-

Can you customize micelle size and drug-loading capacity?

Yes. We precisely control micelle size (typically 10–200 nm), polydispersity, and core-shell structure through advanced self-assembly techniques. Drug loading and encapsulation efficiency are optimized for hydrophobic drugs, nucleic acids, or peptides. We also provide tailored solutions for controlled release, targeted delivery, and multifunctional applications.

-

How do you ensure the quality and consistency of polymer micelles?

BOC Sciences implements a comprehensive quality management system, including particle size, morphology, polymer molecular weight, drug loading, and functionalization verification. Using DLS, TEM, HPLC, NMR, and other advanced instruments, we ensure high purity, reproducibility, and batch-to-batch consistency for research and preclinical applications.

-

Can polymer micelles be used for targeted drug delivery?

Absolutely. We offer micelles functionalized with antibodies, peptides, or small molecules for precise targeting to tumors or specific organs. Combined with stimuli-responsive features, our micelles can enhance cellular uptake, reduce off-target effects, and improve therapeutic outcomes in both in vitro and in vivo applications.

-

Are your polymer micelles suitable for nucleic acid delivery?

Yes. Our polymer micelles efficiently encapsulate siRNA, mRNA, or DNA, improving their stability in biological environments. Functionalization with targeting ligands or responsive groups enhances transfection efficiency. We provide custom designs for gene therapy, mRNA vaccines, or other nucleic acid-based applications, ensuring safe and effective delivery.