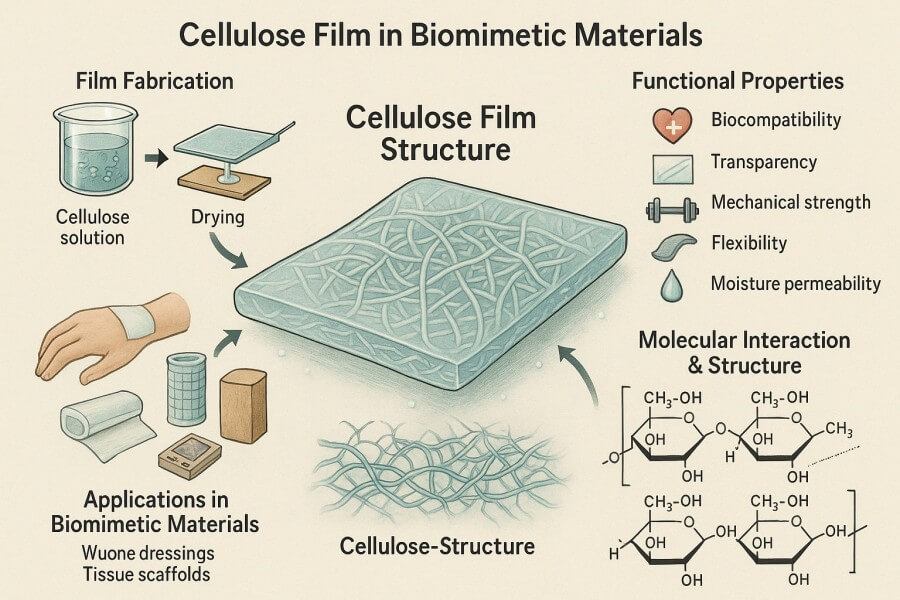

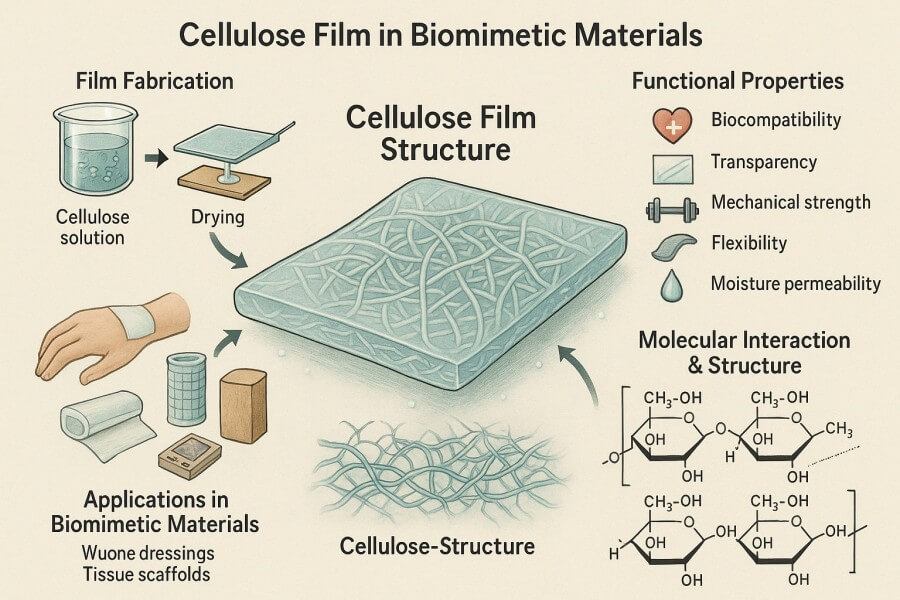

Cellulose Film Preparation

Cellulose films are highly transparent, biodegradable materials with excellent mechanical properties, made from natural cellulose or its derivatives. They combine renewability with environmental friendliness. In the field of biomimetic materials, cellulose films can mimic the structure and function of natural biological tissues, and are widely applied in cutting-edge technologies such as flexible electronics, artificial skin, tissue engineering scaffolds, smart controlled-release membranes, and high-performance functional packaging. These films demonstrate outstanding research value and application potential. BOC Sciences possesses advanced fabrication technologies and extensive development experience, providing clients with comprehensive cellulose film solutions—from laboratory research to pilot-scale production, functional development, and performance optimization. We can precisely control film thickness, porosity, mechanical properties, and multifunctional composites, delivering high-quality, customized films that accelerate scientific breakthroughs and industrial applications.

What We Offer

Cellulose Film Fabrication Supported by BOC Sciences

Leveraging deep expertise in polymer chemistry and cellulose film development, BOC Sciences focuses on providing high-performance, customized, and functional cellulose film solutions for biomimetic material research. Whether for fundamental research, functional development, or industrial production, we offer one-stop services to help clients rapidly advance from concept design to practical application.

Natural Cellulose Films

- High-purity plant-derived cellulose films suitable for packaging, membrane separation, and tissue scaffolds.

- Adjustable thickness, transparency, and mechanical strength to meet diverse application needs.

- Support for both large-scale production and small-batch R&D, ensuring quality and reproducibility.

- Surface modification services available to enhance hydrophilicity or adhesion properties.

Cellulose Ester Films

- Includes films such as cellulose acetate (CA) and cellulose propionate (CP).

- Customizable transparency, flexibility, and heat resistance for electronics, packaging, and optical applications.

- Compatible with solution casting, coating, and composite processes to meet various production needs.

- Surface modification and functional development services enhance application value.

Cellulose Derivative Films

- Includes carboxymethyl cellulose (CMC), hydroxypropyl cellulose (HPC), and methylcellulose (MC) films.

- Solubility, flexibility, and thermal stability can be tailored to meet process requirements.

- Coating, composite, and functional modification services available.

- Supports both laboratory development and industrial production, ensuring consistent performance.

Nanocellulose Films

- Ultra-thin, high-strength films fabricated from cellulose nanofibers or nanocrystals.

- Excellent barrier, transparency, and optical properties for electronics and high-performance composites.

- Surface modification and functional enhancement for improved adhesion or antimicrobial performance.

- Thickness and size can be customized to meet diverse application requirements.

Functionalized Cellulose Films

- Films with antibacterial, conductive, or stimulus-responsive properties.

- Chemical or physical modification to meet specific industrial and biomedical needs.

- Supports coating, composite, or multilayer film designs.

- Technical consultation available to optimize functional film performance.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Customized Cellulose Film Development Services

BOC Sciences integrates material fabrication, performance optimization, and functional modification to provide cellulose film services that support seamless transition from laboratory R&D to pilot-scale and industrial production. Whether natural cellulose films or cellulose derivatives, we offer full-process, customized services—from raw material selection and process optimization to film formation, composite functionalization, and performance evaluation—tailored to biomimetic material applications.

1Raw Material Selection and Pretreatment

- Natural Cellulose: Such as wood pulp, cotton pulp, bamboo pulp, suitable for biodegradable films and biomimetic membrane research.

- Cellulose Derivatives: Such as cellulose acetate, HPC, and CMC; solubility, transparency, and mechanical properties can be adjusted according to functional requirements.

- Pretreatment Processes: Including solvent selection, solubility adjustment, plasticizer addition, and nanocellulose homogenization, providing a solid foundation for high-quality film preparation.

2Biomimetic Material Research Support

- Artificial Skin and Flexible Sensors: Development of flexible, stretchable, transparent, and conductive cellulose films for pressure sensors, humidity sensors, and flexible electronic devices.

- Tissue Engineering Membranes: Porosity-controlled, biocompatible cellulose films for use as cell scaffolds or artificial matrices.

- Controlled-Release and Smart Membranes: Development of drug-release and stimulus-responsive membranes that mimic the permeability, degradation, and functional characteristics of natural cell membranes.

3Film Fabrication Processes

- Solution Casting: Allows control over film thickness, transparency, and mechanical properties; suitable for lab research and small-batch production.

- Stretch Film: Uni- or bi-directional stretching enhances mechanical strength, transparency, and toughness; ideal for biomimetic membranes and flexible electronics.

- Composite Film Fabrication: Combining cellulose films with functional polymers, nanofillers, or bioactive molecules to achieve antibacterial, barrier, conductive, or smart-response functions.

- Drying and Thermal Treatment: Precision drying and thermal setting ensure uniform thickness, improved mechanical properties, and stability; suitable for industrial-scale production.

4Functional Development and Performance Optimization

- Antibacterial and Barrier Functions: Incorporation of natural or synthetic antimicrobial agents, or enhancement of oxygen, water vapor, and oil barrier properties via coating and composite techniques; suitable for food packaging, medical membranes, and biomimetic applications.

- Optical and Conductive Functions: Composite with nanoscale conductive or optical materials for flexible displays, sensors, or smart film applications.

- Biomimetic Functional Design: Customization of porosity, surface chemistry, and mechanical properties for flexible artificial skin, tissue engineering membranes, controlled-release, and smart-response membranes to mimic natural biological film characteristics.

- Performance Evaluation and Process Optimization: Testing of tensile strength, elongation at break, breathability, transparency, and barrier properties; formulation, casting thickness, drying conditions, and stretching ratios optimized to meet application requirements.

Characterization

Cellulose Film Analysis and Performance Evaluation Services

BOC Sciences offers systematic analysis and performance evaluation services, covering physical, mechanical, chemical, and functional testing. Through rigorous and scientific testing systems, we help clients comprehensively understand film characteristics, optimize fabrication processes, and validate product performance reliability.

| Test Category | Test Item | Description / Measured Parameter |

|---|

| Physical Properties | Film Thickness | Measurement of film thickness and uniformity |

| Light Transmittance/Transparency | Determination of optical transmittance to evaluate transparency |

| Surface Morphology | Observation of surface structure and uniformity via optical microscopy or scanning electron microscopy (SEM) |

| Mechanical Properties | Tensile Strength | Measurement of maximum stress under tensile load |

| Elongation at Break | Measurement of extension before film fracture |

| Tear Strength | Evaluation of resistance to tearing |

| Chemical Properties | Composition Analysis | Detection of chemical composition and structure using FTIR, NMR, etc. |

| Moisture Content | Determination of water content and its impact on film properties |

| pH Stability | Assessment of chemical stability under different pH conditions |

| Thermal Properties | Thermogravimetric Analysis (TGA) | Determination of thermal stability and decomposition temperature |

| Differential Scanning Calorimetry (DSC) | Measurement of glass transition temperature and thermal characteristics |

| Functional Properties | Barrier Performance | Evaluation of oxygen, moisture, or oil barrier capability |

| Solubility/Degradability | Testing film solubility or degradation rate under specific conditions |

| Functional Response | Testing antibacterial activity, conductivity, photosensitivity, or mechanosensitivity |

| Environmental Adaptability | Temperature Resistance | Assessment of film performance stability under different temperature conditions |

| Humidity Resistance | Evaluation of mechanical and barrier performance under high humidity |

| Light Resistance | Measurement of aging and property retention under light exposure |

Advantages

Advantages of BOC Sciences' Cellulose Film Services

- Extensive Technical Expertise: Our team includes experienced chemical engineers and biochemistry specialists familiar with the properties of natural cellulose and cellulose derivatives, modification techniques, and film fabrication processes.

- Full-Process Custom Services: From raw material selection, solution preparation, film casting, drying, and stretching to functional modification, composite formation, and performance testing, we provide one-stop solutions.

- Support for Multiple Types of Cellulose Films: We offer fabrication of natural cellulose films, cellulose ester films (e.g., cellulose acetate, cellulose nitrate), cellulose ether films (e.g., hydroxypropyl cellulose, methylcellulose, carboxymethyl cellulose), and functional composite films.

- Flexible Customization: Films can be customized according to project requirements, including type, thickness, functionality, and batch scale, suitable for laboratory, pilot, and small-scale production.

- Focus on Biomimetic Material Development: Specialized technical solutions and customized development services are available for biomimetic membranes, flexible sensors, tissue engineering scaffolds, and controlled-release films.

- Strict Quality Control: High-standard analytical and testing methods are applied throughout the process, including mechanical performance testing, thickness uniformity, breathability, and transparency assessments, ensuring stable and reliable film performance.

Service Process

Professional Cellulose Film Service Workflow

BOC Sciences provides a one-stop cellulose film service from concept design to industrial production, covering research, functional development, and performance optimization. Our workflow is designed to help clients efficiently achieve precise, controlled, and high-quality cellulose films for both scientific research and product development.

1Requirement Communication & Solution Design

- We conduct in-depth discussions with clients to understand application scenarios, performance requirements, functional needs, and target specifications.

- Based on the client's research direction or product goals, we design a tailored fabrication and functionalization plan to ensure films meet expectations in mechanical properties, transparency, porosity, and functionality.

- At this stage, preliminary feasibility analyses—such as material selection, process applicability, and performance prediction—can also be conducted to establish a scientific foundation for subsequent fabrication.

2Raw Material Selection & Formulation Optimization

- Select the most suitable raw materials according to film type, including natural cellulose (wood pulp, cotton pulp, bamboo pulp) or cellulose derivatives (cellulose acetate, hydroxypropyl cellulose, methylcellulose, carboxymethyl cellulose).

- Evaluate raw material solubility, molecular weight, purity, and processability, optimizing formulations based on target film properties.

- Plasticizers, crosslinking agents, or functional fillers can be added to enable subsequent functional development.

3Film Fabrication & Process Development

- Employ various fabrication techniques such as solution casting, film stretching, thermal setting, and composite film formation to achieve uniform thickness, excellent mechanical performance, and high transparency.

- Fine-tune process parameters (solution concentration, casting speed, drying temperature, stretching ratio, etc.) to ensure stable and reliable film properties.

- Develop single-layer or multilayer composite films to meet the needs of different biomimetic materials and functional membranes.

4Functional Development & Composite Modification

- Functionalize films according to application goals, including antibacterial, barrier, or smart-response properties.

- Single-function or multifunctional composites can be produced to meet complex application requirements.

5Performance Evaluation & Quality Control

- Comprehensive testing is conducted on completed films, including tensile strength, elongation at break, breathability, transparency, barrier properties, and functional response performance.

- Standardized quality control processes rigorously assess thickness, uniformity, porosity, and functionalization effectiveness, ensuring compliance with high standards for research or industrial applications.

- Test results guide further optimization of process parameters and formulations for iterative performance improvement.

6Pilot-Scale & Batch Production Support

- Scale up laboratory results to pilot or industrial production, from gram to kilogram or larger quantities.

- Adjust scale-up process parameters to maintain uniformity, stable performance, and functional reliability in large-scale production.

- Support reproducibility testing across batches, providing data and technical assurance for mass production.

Applications

Applications of Cellulose-Based Films in Biomimetic Materials

Cellulose-based films, with natural renewability, high transparency, excellent mechanical properties, and biodegradability, serve as a crucial foundation for biomimetic material research. Through various processing and functionalization methods, cellulose films can mimic natural biological structures and support diverse biomimetic applications.

Biomimetic Flexible Skin & Sensors

Flexible, stretchable, and transparent cellulose films serve as substrates for artificial skin, providing sensitivity to pressure, touch, and humidity. By incorporating conductive materials, photosensitive molecules, or nanofillers, films can mimic biological skin functions, applicable in flexible sensors, wearable electronics, and smart robotics.

Tissue Engineering & Biomedical Membranes

Porosity-controlled, biocompatible cellulose films mimic natural extracellular matrices, suitable for tissue engineering scaffolds and cell culture membranes. By adjusting pore size, thickness, and surface chemistry, films promote cell adhesion, proliferation, and differentiation, providing ideal carriers for regenerative medicine, wound repair, and artificial tissue construction.

Controlled-Release & Smart-Response Membranes

Cellulose films can act as carriers for drug or functional molecule release, with material modifications enabling pH-, temperature-, or humidity-responsive behavior. Their selective permeability and controlled degradability allow precise regulation of active substance release, suitable for smart drug delivery systems, functional food packaging, and environmentally responsive materials.

High-Performance Biomimetic Packaging & Protective Films

Cellulose films offer high transparency, biodegradability, and excellent barrier properties, mimicking natural membrane structures. By adjusting film density, thickness, and porosity, oxygen, moisture, or oil barrier properties are enhanced while maintaining flexibility and transparency, suitable for food, pharmaceutical, and high-end protective film applications.

FAQs

Frequently Asked Questions

-

What is cellulose film?

Cellulose film is a high-performance material made from natural cellulose or its derivatives, featuring transparency, flexibility, and tear resistance. It is eco-friendly and biodegradable, serving as a sustainable alternative to traditional plastics. Depending on its source and chemical modification, cellulose film can be classified as regenerated cellulose film, cellulose acetate film, or cellulose nitrate film, with applications in packaging, medical materials, electronics, and optical films.

-

How is cellulose film made?

The fabrication of cellulose film typically involves cellulose dissolution, film formation, and drying. Natural cellulose or derivatives such as CMC and cellulose acetate are dissolved in suitable solvents to form a uniform solution, which is then cast, calendared, or spun into films, followed by drying, stretching, and surface treatment to achieve the desired thickness and properties. Different fabrication methods allow control over mechanical strength, transparency, and biodegradability to meet industrial needs.

-

What is carboxymethyl cellulose film?

Carboxymethyl cellulose (CMC) film is a highly transparent film prepared from CMC aqueous solutions, with excellent film-forming properties and solubility control. Its mechanical strength, moisture resistance, and biocompatibility can be enhanced via chemical modification or crosslinking. CMC films are widely used in food packaging, medicinal controlled-release films, biodegradable materials, and biomaterial research, offering clear advantages in sustainability.

-

What is cellulose acetate film?

Cellulose acetate film is made from cellulose acetate, offering high transparency, good mechanical performance, and chemical stability. It features excellent water resistance and thermal stability, suitable for optical films, photographic films, electronic protective films, and food and pharmaceutical packaging. Adjusting the degree of acetylation and processing conditions can tailor flexibility, light transmission, and barrier properties for diverse industrial and research applications.

-

What is cellulose nitrate film?

Cellulose nitrate film, made from nitrated cellulose, is highly transparent, glossy, and plastic. It is widely used in photographic films, coatings, and specialized industrial products. Due to its flammability and chemical sensitivity, strict safety controls are required during fabrication, storage, and transport. Stabilizers or modified processes can improve mechanical strength and durability.

-

What is regenerated cellulose film?

Regenerated cellulose film is produced by dissolving and regenerating natural cellulose, such as viscose film. It features good mechanical strength, transparency, flexibility, and controllable breathability and moisture permeability, while being eco-friendly and biodegradable. Applications include food packaging, medical dressings, filtration membranes, and cosmetic films.

-

What is biodegradable cellulose film?

Biodegradable cellulose film, made from natural or chemically modified cellulose, can decompose naturally through microbial action, reducing plastic pollution. Its mechanical strength, barrier properties, and flexibility can be tuned by adjusting thickness, crosslinking, or additives. It is valuable in eco-friendly packaging, disposable tableware, medical degradable films, and agricultural films.

-

What are the properties of cellulose film?

Cellulose film exhibits high transparency, flexibility, strong mechanical performance, and chemical resistance. Depending on type, its surface is smooth, breathability can be controlled, and barrier, antibacterial, or biodegradable properties can be conferred. Derivative films can undergo chemical modification to control solubility, enhance thermal stability, or functionalize surfaces, making them widely applicable in food, pharmaceutical, electronics, and optical materials.

-

What is the use of cellulose film?

Cellulose film is widely used in food, pharmaceutical, and industrial applications, including packaging films, medicinal controlled-release membranes, medical dressings, electronic protective films, and optical films. Its transparency, flexibility, barrier properties, and biodegradability make it an ideal sustainable alternative to plastics and a key material in eco-friendly packaging, biomaterial research, and functional industrial films.