Chitosan Coating Preparation

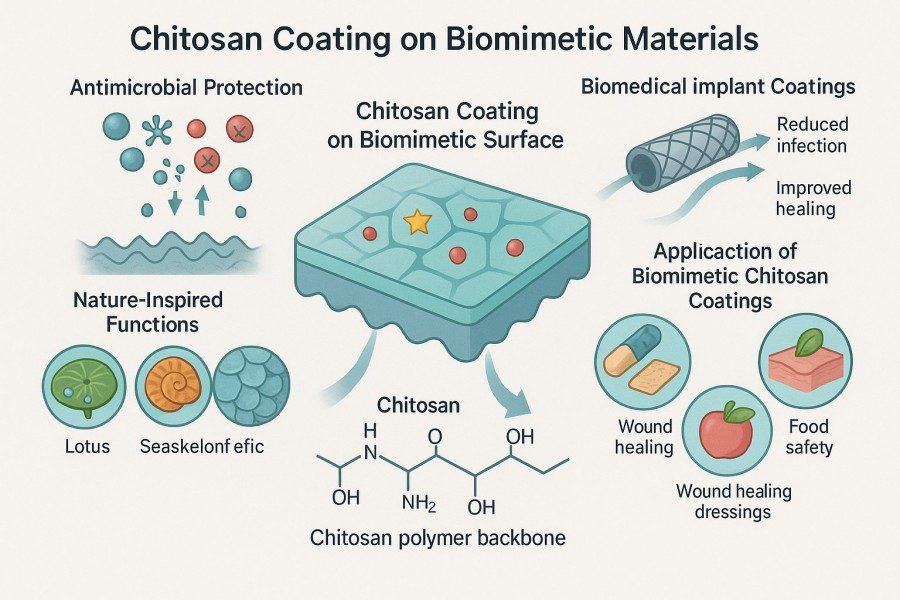

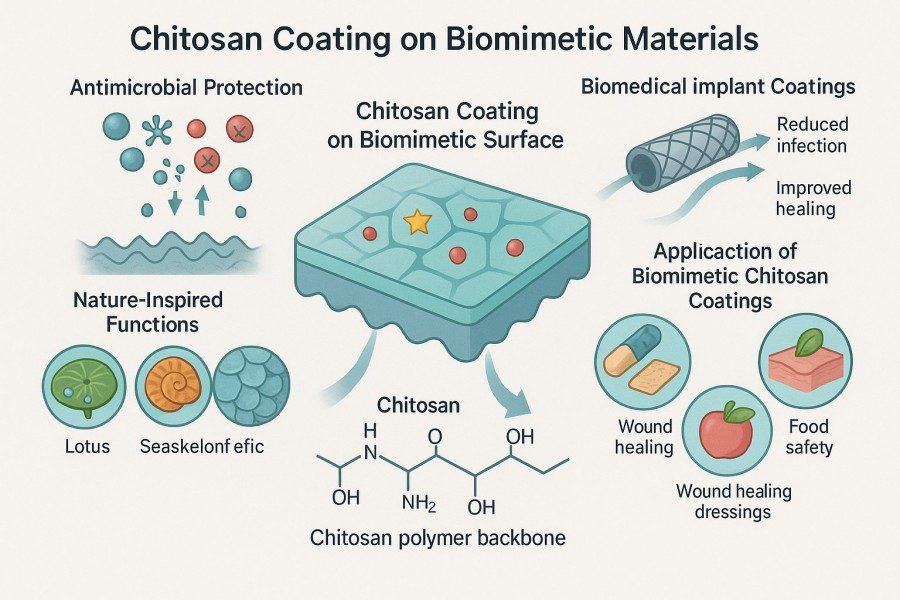

Chitosan coating refers to the technique of covering a material surface with chitosan via physical adsorption, chemical crosslinking, or self-assembly, thereby improving surface properties and imparting specific biological functions. Chitosan coatings enhance biocompatibility, antibacterial activity, cell adhesion, and drug-loading capacity, providing foundational support for tissue engineering scaffolds, medical devices, drug delivery systems, and functional biomimetic materials. BOC Sciences offers comprehensive chitosan coating preparation and functional development services for a wide range of materials, including biomimetic materials, nanoparticles, liposomes, and biopolymers. We design customized coating solutions tailored to client needs, covering dip-coating, spin-coating, spray-coating, layer-by-layer assembly, and composite development, with support for crosslinking, drug loading, and smart functionalization. Coupled with full characterization, small-scale scale-up, and process optimization services, we ensure uniform and stable coatings that meet high standards for both research and industrial production, providing reliable and efficient technical support.

What We Offer

Chitosan Coated Materials Supported by BOC Sciences

We can design optimized coating solutions for chitosan of different molecular weights and degrees of deacetylation, offering diverse preparation methods including dip-coating, spin-coating, spray-coating, layer-by-layer assembly, and nano-composites. Through chemical crosslinking, functional modifications, and composite strategies, we enable antibacterial activity, drug delivery, targeted transport, and smart responsiveness. Comprehensive characterization techniques and small-scale scale-up services ensure stable and uniform coatings, fulfilling the requirements of research development and industrial production, helping clients efficiently achieve material functionalization and innovative applications.

Chitosan Coated Liposomes

Supports coating of both conventional and functional liposomes, improving stability, drug encapsulation efficiency, and targeted delivery performance. Suitable for small molecule drugs, proteins, nucleic acids, and other bioactive molecules, enhancing bioavailability and functional persistence to meet research and development needs.

Chitosan Coated Nanoparticles

Applicable to magnetic nanoparticles, PLGA nanoparticles, gold nanoparticles, and more. The coating enhances biocompatibility, cell adhesion, and enables drug or functional molecule loading for controlled release and precise applications.

Chitosan Coated Microspheres/Microcapsules

Suitable for drug sustained-release, nutrient delivery, and tissue engineering applications. By controlling porosity, degradation rate, and surface functionalization, sustained release or targeted delivery can be achieved, improving stability and efficacy of active molecules for diverse material development needs.

Chitosan Coated Proteins

Chitosan surface modification protects protein structure and functional activity, enhancing solubility and stability, supporting drug delivery and tissue engineering applications. Crosslinking or composite strategies can be combined to achieve targeted delivery and controlled release, meeting advanced R&D requirements.

Chitosan Coated Peptides

Provides a stable surface environment for peptides, preventing degradation and enhancing bioactivity. Chitosan coatings can be used in functional delivery systems to improve cell adhesion and targeting, suitable for drug development, vaccine carriers, and tissue engineering research.

Chitosan Coated DNA/RNA

Chitosan protects nucleic acid structures, improving solubility and biological stability, supporting in vitro and in vivo delivery applications. Coatings enable controlled release and targeted delivery, fulfilling the needs of gene therapy, vaccine development, and functional nucleic acid material research.

Chitosan Antibacterial Coating

Leverages chitosan's natural positive charge and bioactivity to inhibit bacterial growth and protect against biofilms. Suitable for medical device surfaces, food packaging, and functional biomimetic materials, enhancing antibacterial performance, reducing infection risk, and enabling synergistic antibacterial effects when combined with drugs or nanoparticles.

Chitosan Coated Functional Materials

Includes metal ion composites, nanocomposites, and biomimetic scaffolds. Chitosan coatings confer antibacterial, conductive, smart-responsive, and bioactive surface functions, expanding applications in medical, environmental, and functional biomimetic materials.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Core Chitosan Coating Techniques for Biomaterials

BOC Sciences offers professional chitosan coating preparation and development services for the full research, development, and production process of biomimetic materials. We select chitosan raw materials of various molecular weights and degrees of deacetylation according to client requirements and provide multiple coating methods including dip-coating, spin-coating, spray-coating, layer-by-layer assembly, and nano-composites, supporting chemical crosslinking and functional development. Coupled with characterization analysis and small-scale scale-up services, we ensure uniform and stable coatings that meet functional requirements such as antibacterial activity, drug delivery, and cell adhesion, offering comprehensive technical support for research and industrial applications.

1High-Quality Chitosan Materials with Tunable Properties

- Adjustable Molecular Weight: Low, medium, and high molecular weight chitosan to meet different coating performance needs.

- Controlled Degree of Deacetylation: Precisely modulates solubility, antibacterial properties, and biocompatibility.

- High Purity and Low Impurities: Ensures coating stability and reproducibility, minimizing experimental interference.

2Diverse Coating Preparation Methods

- Dip-Coating and Spin-Coating: Suitable for flat and regular surfaces, providing uniform thickness with controllable porosity.

- Spray-Coating and Electrospinning: Ideal for complex or microstructured surfaces, forming nanoscale functional coatings.

- Layer-by-Layer Assembly: Achieves multifunctional composite coatings through electrostatic adsorption or chemical interaction, with precise control of thickness and function distribution.

- Nano-Composite Coatings: Combines chitosan with nanoparticles, proteins, or metal ions for antibacterial, conductive, or drug-loading multifunctionality.

3Functional Development Capabilities

- Antibacterial Function: Uses chitosan's amino positive charge to inhibit bacterial adhesion and biofilm formation.

- Drug Delivery and Controlled Release: Crosslinking or composites enable sustained release, targeted delivery, and long-term bioactivity maintenance.

- Cell Adhesion and Tissue Engineering Support: Optimizes surface chemistry and microstructure to promote cell proliferation and differentiation.

- Smart Responsive Function: Develops pH-sensitive, temperature-responsive, or targeted coatings for advanced biomimetic material applications.

4Characterization and Quality Control

- Surface Morphology Analysis: SEM and AFM to examine coating thickness, porosity, and roughness.

- Chemical Structure Verification: FTIR and XPS to confirm functionalization and crosslinking.

- Physical Performance Testing: Mechanical properties, contact angle, and thermal stability assessments.

- Biological Performance Evaluation: In vitro cell adhesion, proliferation, and antibacterial activity verification.

Advantages

Why Choose BOC Sciences for Advanced Chitosan Coating Solutions?

- Precise Coating Thickness and Porosity Control: Advanced dip-coating, spin-coating, and spray-coating techniques allow precise control over coating thickness, porosity, and surface microstructure, enabling material functionalization and controlled release.

- Multifunctional Composite Coating Development: Chitosan can be combined with nanoparticles, metal ions, or bioactive molecules to achieve multifunctional coatings with antibacterial, conductive, targeted delivery, and smart-responsive properties.

- Chemical Crosslinking and Functional Modification: Various crosslinking strategies and chemical modification options are available, including water-soluble crosslinkers, photo-crosslinking, and pH-sensitive modifications, enabling controlled degradation and functional applications.

- Accurate Surface Characterization and Performance Evaluation: Equipped with SEM, AFM, FTIR, contact angle measurement, and mechanical testing, coatings can be precisely evaluated for uniformity, structure, and functional performance, ensuring reproducibility.

- Targeted Delivery and Controlled Release Technologies: Chitosan coatings enable targeted delivery and controlled release of drugs, proteins, nucleic acids, and other molecules, supporting drug delivery systems and functional biomaterials research.

- End-to-End Custom Services: From chitosan material selection and coating design to functional development and characterization, we provide comprehensive customized solutions, ensuring precise and controllable coating performance and application outcomes.

- Extensive Experience and Professional Team: Our team of experienced chemists and biomaterials experts is skilled in biomimetic material surface functionalization, offering technical guidance, process optimization, and tailored solutions to ensure efficient R&D and production.

- Flexible Development and Scale-Up Support: Services include small-scale development, process optimization, and industrial technology transfer, helping clients transition quickly from laboratory research to pilot and production stages for controlled and efficient industrial application.

Service Process

From Lab to Industrial Scale: Full Process of Chitosan Coating Preparation

To help clients efficiently complete chitosan coating development, BOC Sciences provides standardized and customizable service workflows covering everything from requirement consultation and material selection to coating preparation, functional development, and industrial scale-up. Our process ensures stable and uniform coatings while enabling antibacterial, drug delivery, and smart-responsive functionalities based on client application requirements, supporting smooth research and production.

1Requirement Consultation and Solution Design

We communicate closely with clients to fully understand material type, surface properties, application scenarios, and performance goals. Based on this analysis, we design personalized coating solutions, including coating thickness, porosity, functionalization direction, and characterization plan, ensuring scientifically feasible outcomes.

2Material Selection and Preliminary Preparation

Chitosan raw materials of different molecular weights, degrees of deacetylation, and purity are selected according to client needs. Solution preparation and preliminary coating tests are conducted to evaluate uniformity, stability, and surface adhesion, providing a reliable basis for subsequent functional development.

3Functional Development and Optimization

Coatings are developed with crosslinking, composites, or drug/active molecule loading according to specific applications. Optimizing thickness, uniformity, porosity, and crosslinking density achieves antibacterial, controlled release, targeted delivery, or smart-responsive functionalities to meet diverse R&D and production requirements.

4Characterization and Validation

Multiple analytical techniques are used for comprehensive coating characterization, including SEM, AFM, FTIR, contact angle measurement, and mechanical testing. Coating morphology, chemical structure, physical, and biological performance data are fully documented to ensure quantifiable validation of functional goals.

5Small-Scale Scale-Up and Process Optimization

Coating preparation parameters are optimized based on experimental data to achieve small-scale scale-up and pilot process translation. Process optimization ensures uniform and stable coatings during batch production, providing reliable technical support for industrial applications.

6Technical Support and After-Sales Service

BOC Sciences provides experimental reports, operational guidance, and long-term technical support to address challenges during R&D and production. Continuous communication and optimization ensure clients successfully achieve innovative research and commercial applications of chitosan coatings.

Applications

Applications of Chitosan Coatings in Biomimetic Materials

BOC Sciences' chitosan coating services are widely applicable in biomimetic material research, development, and industrial production. We design optimized coatings for different material types and application requirements, enhancing biocompatibility, creating functionalized surfaces, and enabling controlled release and smart responsiveness. Whether in tissue engineering, drug delivery, bioelectronics, or environmental and food applications, our chitosan coating technology effectively enhances material performance and application value, supporting scientific innovation and high-end product development.

Tissue Engineering and Regenerative Medicine

- Bone and Cartilage Scaffold Surface Modification: Chitosan coatings improve scaffold biocompatibility, enhancing cell adhesion and bone/cartilage regeneration.

- Skin Substitutes and Wound Dressings: Provides antibacterial, healing-promoting, and drug-release functions suitable for complex wound repair.

- Biodegradable Medical Device Surfaces: Optimizes implant surface properties to reduce immune rejection and improve long-term biosafety.

Drug Delivery and Controlled Release Systems

- Nanoparticle and Microsphere Coatings: Enables targeted drug delivery and sustained release, improving drug bioavailability.

- Functionalized Microneedles and Carriers: Enhances adhesion and penetration, boosting delivery efficiency of drugs or biomolecules.

- Oral and Local Delivery Systems: Chitosan coatings for oral tablets or local carriers allow controlled drug release and localized delivery.

Biosensing and Bioelectronics

- Sensor Surface Modification: Improves biomolecule immobilization efficiency and detection sensitivity.

- Bioelectronic Material Coatings: Ensures compatibility with biological systems, suitable for in vitro diagnostics and wearable devices.

- Smart-Responsive Material Development: Chitosan coatings impart temperature, pH, or enzyme responsiveness to materials.

Environmental and Food Applications

- Antibacterial and Anti-Fouling Coatings: Mimics natural bio-surface antibacterial mechanisms, suitable for eco-friendly materials and food packaging.

- Biodegradable Functional Films: Provides antibacterial and biodegradable functions in water treatment and packaging, balancing performance and sustainability.

- Food Preservation and Nutrient Coatings: Chitosan coatings for packaging and preservation films extend food shelf life.

FAQs

Frequently Asked Questions

-

What is chitosan coating?

Chitosan coating refers to the uniform coverage of the natural polysaccharide chitosan on a material surface to form a functionalized film, improving biocompatibility and surface properties. This coating can be applied to nanoparticles, liposomes, microspheres, scaffolds, and medical devices. Through crosslinking or composite treatments, it can provide antibacterial, controlled release, or smart-responsive functionalities.

-

How to make chitosan coating?

Chitosan coatings are typically prepared by dissolving chitosan of different molecular weights and degrees of deacetylation in an acidic solution, followed by application via dip-coating, spin-coating, or layer-by-layer assembly. Coating thickness, porosity, and functional modifications can be adjusted according to application requirements to achieve antibacterial, controlled release, and targeted functionalities.

-

What are chitosan coated liposomes?

Chitosan-coated liposomes form a uniform layer on the liposome surface, enhancing stability and drug encapsulation efficiency while enabling targeted delivery. They are suitable for small molecule drugs, proteins, and nucleic acids. By adjusting chitosan thickness and crosslinking density, controlled release and functionalized delivery can be achieved.

-

What are chitosan coated nanoparticles?

Chitosan-coated nanoparticles improve biocompatibility, surface stability, and cell adhesion. Common types include magnetic nanoparticles, PLGA nanoparticles, and gold nanoparticles. The coating allows drug or active molecule loading, regulates release rates, supports targeted delivery, and enables functionalized applications, widely used in drug delivery and biomimetic material research.

-

What is chitosan antimicrobial coating?

Chitosan antimicrobial coatings mimic the natural antibacterial mechanism of polysaccharides, effectively inhibiting bacterial adhesion and growth. They are commonly applied to medical device surfaces, food packaging, wound dressings, and environmentally friendly materials, providing long-lasting antibacterial, anti-fouling, and biosafety protection while supporting functionalized coating development and surface modification.

-

What are chitosan coated alginate beads?

Chitosan-coated alginate beads feature a uniform chitosan film on the bead surface, enhancing bead stability and controlled release performance. They are widely used in drug sustained release, protein and nucleic acid delivery, and tissue engineering scaffolds. Porosity, degradation rate, and bioactivity can be tuned to achieve controlled release and targeted functionalities.

-

What is chitosan coating protocol?

The chitosan coating protocol includes material selection, solution preparation, surface coating, crosslinking or composite treatment, and characterization analysis. Using dip-coating, spin-coating, or layer-by-layer assembly, uniform and stable coatings can be achieved. Thickness, porosity, and functional properties can be optimized according to application goals to meet requirements for drug delivery, antibacterial activity, or smart-responsive functions.