Polyurethane Film Preparation

Medical-grade polyurethane (PU) films refer to thin film materials prepared from high-molecular-weight polyurethane through specialized film processing techniques, compliant with medical device or pharmaceutical standards. Their core feature lies in the chemical composition and physical properties of the material, which meet safety requirements for human applications, while providing excellent mechanical strength, flexibility, and controllable breathability. With the rapid advancement of biomedical engineering and biomimetic material technologies, PU films, thanks to their outstanding mechanical performance, flexibility, and biocompatibility, have become essential materials in medical devices, tissue engineering, drug delivery, and wound care. In the field of polyurethane films, BOC Sciences provides end-to-end services from design and development to scalable production, helping research institutions and industrial clients efficiently achieve their medical, healthcare, and biomimetic material project goals. Our services cover standard fabrication and can also be customized for specific functions such as breathability control, waterproofing, antibacterial performance, drug release, and degradability, ensuring optimal performance of PU films in diverse biomimetic applications.

What We Offer

Polyurethane Films Offered by BOC Sciences

Different applications in medical and biomimetic material fields require distinct PU film properties. BOC Sciences offers a variety of medical-grade PU films and customization services, covering everything from chemical structure to functional modifications, and from single-layer films to composite films. Through flexible fabrication processes and precise functional control, we provide highly customizable, performance-controlled PU film solutions that meet diverse application requirements.

Polyether-based PU Film

- Highly flexible films suitable for catheters and skin-conforming medical dressings.

- Customizable tensile strength and elasticity to meet various biomimetic material needs.

- Antibacterial, surface hydrophilicity/hydrophobicity adjustment, and drug-loading modification services available.

Polyester-based PU Film

- Biodegradable films for tissue engineering and short-term medical applications.

- Adjustable hard segment/soft segment ratios to balance mechanical properties and flexibility.

- Customizable drug-release films and functional microporous membranes.

Polycarbonate-based PU Film

- Highly transparent, heat-resistant, and oxidation-resistant films suitable for medical device protection.

- Available in single-layer, composite, and microporous formats.

- Surface modifications for antibacterial, antithrombotic, and optimized breathability.

Breathable PU Film

- Controlled microporous structure to maintain oxygen and water vapor exchange.

- Suitable for wound dressings, skin-care materials, and conformal applications.

- Customizable thickness, breathability, and mechanical properties.

Waterproof/Fluid-Barrier PU Film

- Dense film layer design to block blood and bodily fluid penetration.

- Suitable for catheter coatings, surgical dressings, and medical device protection.

- Can be combined with antibacterial and drug-release functionalities.

Biodegradable/Drug-Release PU Film

- Gradually degrades in vivo or in vitro, reducing the need for secondary surgery.

- Supports loading of drugs, antibacterial agents, or growth factors for localized sustained release.

- Customizable degradation rate and functional film options.

Antibacterial/Antiviral PU Film

- Surface-modified with silver ions, copper ions, or antibacterial polymers.

- Applicable for hospital dressings, protective films, and wound coverings.

- Customizable antibacterial strength and film thickness.

Composite PU Film

- PU films combined with nonwoven fabrics, medical gauze, or other polymers.

- Enhances flexibility, regulates waterproofness and breathability, and allows functional surface modifications.

- Customizable composite layers, thickness, and functionalities for multi-scenario applications.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

BOC Sciences Medical-Grade Polyurethane Film Solutions

From raw material design and film fabrication to functional modification, we provide highly customizable solutions tailored to customer needs, helping biomimetic material and medical film projects achieve optimized performance and rapid implementation. Our services cover PU film design, processing, functionalization, and performance evaluation, ensuring each film meets expected standards in mechanical properties, biocompatibility, and application-specific functionality.

1Custom PU Film Synthesis

- Synthesize medical-grade PU materials according to customer-provided molecular structures or performance requirements.

- Offer multiple chemical structure options including polyether, polyester, and polycarbonate types.

- Adjustable hard segment/soft segment ratios to achieve different flexibility, tensile strength, and wear resistance.

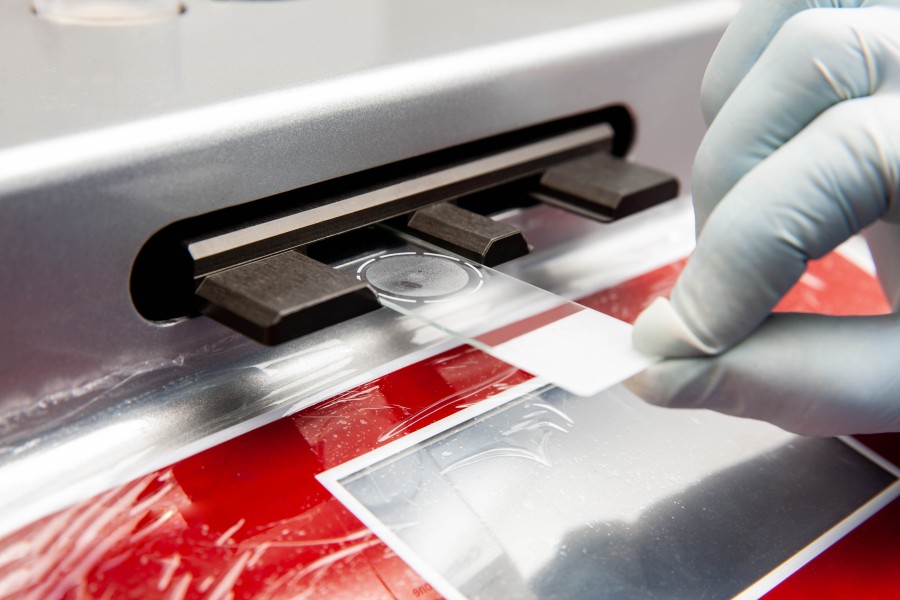

2Film Fabrication & Process Optimization

- Various fabrication techniques including solution casting, hot extrusion, coating, and composite film formation.

- Capable of producing single-layer, composite, and microporous films.

- Precise process control to achieve uniform thickness, controllable breathability, waterproofing, and fluid-barrier properties.

3Functionalization & Modification Services

- Antibacterial and antiviral surface treatments; silver, copper ions, or antibacterial polymer modifications.

- Drug release and growth factor loading for localized sustained therapy.

- Surface hydrophilicity/hydrophobicity adjustment to optimize adhesion and permeability.

4Analysis & Quality Control

- Comprehensive physicochemical performance testing, including tensile strength, elongation at break, thickness uniformity, transparency, breathability, and water resistance.

- Biocompatibility assessment: cell compatibility, immune response, and degradation product safety analysis.

- Detailed testing reports ensuring film performance meets medical application requirements, with optional custom performance validation plans.

Advantages

Polyurethane Film Services & Technical Advantages

- Highly Customizable Solutions: Tailor the chemical structure, mechanical properties, and functional features of PU films to meet diverse application needs, including wound care, catheter protection, and tissue engineering.

- End-to-End Technical Support: From raw material selection and polyurethane synthesis to film fabrication, functional modification, and performance testing, we provide one-stop solutions to accelerate project implementation.

- Extensive Biomimetic Material Experience: Mature expertise in soft tissue engineering, wound dressings, drug delivery, and medical device protection, offering targeted technical solutions and application guidance.

- Comprehensive Physicochemical Testing: Full evaluation of thickness, tensile strength, elongation at break, elasticity, breathability, and water resistance to ensure films meet project specifications.

- Biocompatibility and Safety Assurance: Cell compatibility, immune response, and degradation product safety analyses ensure the reliability and safety of medical-grade PU films in applications.

- Rapid Response and Technical Consultation: A professional R&D team provides prompt technical support and consultation, facilitating smooth progress for research and industrial projects.

- Custom Functionalization Services: Support for antibacterial, drug-release, and surface hydrophilicity/hydrophobicity modifications, optimizing film performance for specific application scenarios and enhancing product value.

Service Process

Polyurethane Film Preparation and Fabrication Services

BOC Sciences provides standardized and customizable PU film fabrication processes, covering the full workflow from requirements analysis to industrial-scale delivery. We adjust processes and functions according to project needs, ensuring each film meets application performance and biocompatibility standards.

1Requirements Analysis & Solution Design

- Engage with clients to understand project goals, application scenarios, and functional requirements, including film type, thickness, and performance criteria.

- Assess specific application needs for mechanical properties, breathability, water resistance, degradability, and functionalization.

- Develop chemical structure design, film type selection, and fabrication process plans to ensure feasibility and efficiency.

2Raw Material & Polymer Synthesis

- Synthesize PU materials according to design, with options including polyether, polyester, or polycarbonate monomers.

- Precisely control hard segment/soft segment ratios to optimize film flexibility, tensile strength, and wear resistance.

- Perform molecular weight control, chain segment modification, and functionalization, including antibacterial, drug-loading, or surface hydrophilicity/hydrophobicity adjustments.

3Film Fabrication & Forming

- Offer multiple fabrication techniques such as solution casting, hot extrusion, and coating to meet varying thickness and structural requirements.

- Produce single-layer, composite, or microporous films suitable for wound dressings, catheter protection, tissue engineering scaffolds, and more.

- Precisely control process parameters to ensure uniform thickness, smooth surfaces, and achieve designed breathability and water resistance.

4Performance Control & Functionalization

- Functional modifications per client requirements, including antibacterial, antiviral, drug-release, or growth factor loading.

- Adjust breathability, water resistance, elasticity, and tensile strength for optimized performance in different applications.

- Surface hydrophilicity/hydrophobicity adjustments enhance adhesion and material adaptability for medical and biomimetic applications.

5Testing & Quality Validation

- Conduct physical property tests including tensile strength, elongation at break, thickness uniformity, breathability, and water resistance.

- Evaluate chemical properties such as molecular weight distribution, crosslinking degree, and hard/soft segment ratios.

- Perform biocompatibility tests including cell compatibility, immune response, and degradability analyses to ensure film safety.

- Provide detailed performance reports to help clients evaluate compliance with experimental or application standards.

6Delivery & Post-Support

- Offer sample production, small-batch trials, and industrial-scale delivery to meet different R&D or production stages.

- Technical team provides follow-up optimization, functional modifications, and application guidance to accelerate product development and industrialization.

- Formulations and processes can be flexibly adjusted based on client feedback for continuous film performance improvement.

Applications

Polyurethane Films: Key Applications in Medical & Biomimetic Fields

With excellent mechanical properties, flexibility, and biocompatibility, PU films are widely used in medical and biomimetic materials. BOC Sciences offers multiple types of medical-grade PU films and can perform functional modifications to meet diverse applications, including wound care, catheter protection, tissue engineering, drug delivery, and medical device protection.

Medical Dressings & Wound Care

- Breathable, waterproof, and antibacterial, suitable for burns, ulcers, and surgical incisions.

- Transparent for wound observation, reducing dressing replacement frequency.

- Can integrate drug-release functionality to promote tissue repair.

Catheter & Medical Device Protection

- High flexibility and wear resistance reduce vascular or tissue damage.

- Surface modifications prevent thrombosis and provide antibacterial properties.

- Transparent films facilitate operation and monitoring.

Tissue Engineering & Regenerative Medicine

- Provides support films to promote cell adhesion and tissue regeneration.

- Biodegradable films match tissue repair rates, avoiding secondary surgeries.

- Can load growth factors or drugs for localized therapy.

Drug Delivery Systems

- PU films serve as drug carriers to control release rates.

- Applicable for localized anti-inflammatory, antibacterial, and tissue repair therapies.

- Supports customization of film thickness and porosity for precise release performance.

FAQs

Frequently Asked Questions

-

What is a polyurethane film?

A polyurethane film is a thin, flexible polymer sheet made from polyurethane. It is durable, transparent, and resistant to water and bacteria while remaining breathable. Its elasticity and strength make it suitable for protective coatings, packaging, and medical applications. The film can conform to surfaces, provide barrier protection, and allow gas exchange, making it versatile for industrial and healthcare uses.

-

What are the medical uses of polyurethane?

Polyurethane is widely used in medicine due to its flexibility, biocompatibility, and durability. It serves in wound dressings, catheters, implantable devices, and surgical films. Its ability to resist bacteria, allow oxygen permeability, and maintain moisture balance makes it ideal for skin healing. Polyurethane is also used in medical tubing, scaffolds for tissue engineering, and protective coatings for medical equipment.

-

Is polyurethane film safe for skin?

Yes, polyurethane film is generally safe for skin when medical-grade materials are used. It is non-toxic, hypoallergenic, and designed to prevent irritation. The film allows skin to breathe while protecting it from bacteria, moisture, and external contaminants. Its flexibility ensures it conforms to body contours without causing pressure or friction, making it suitable for wound care, protective coverings, and other skin-contact applications.

-

Is medical grade polyurethane safe?

Medical-grade polyurethane is considered safe for human use. It undergoes strict quality control and testing for biocompatibility, cytotoxicity, and chemical safety. It is used in direct skin contact applications such as wound dressings, catheters, and implantable devices. Medical-grade polyurethane is designed to minimize allergic reactions and irritation while providing durability, flexibility, and resistance to bacteria, ensuring safe and reliable performance in healthcare settings.

-

What is the use of polyurethane film?

Polyurethane film is used as a protective barrier in medical, industrial, and consumer applications. In healthcare, it serves as wound dressings, surgical drapes, and skin protectors. Industrially, it functions as packaging, surface coatings, and adhesives. Its key features include water resistance, breathability, flexibility, and transparency. The film protects surfaces or skin while allowing gas exchange, reducing infection risks, and maintaining hygiene.

-

What is a polyurethane film dressing?

A polyurethane film dressing is a thin, flexible medical dressing used to cover wounds. It is transparent, waterproof, and breathable, allowing oxygen and moisture vapor to pass through while protecting against bacteria and external contaminants. These dressings promote a moist healing environment, reduce infection risk, and allow clinicians to monitor wound progress without frequent removal. They are commonly used for burns, surgical sites, and minor injuries.