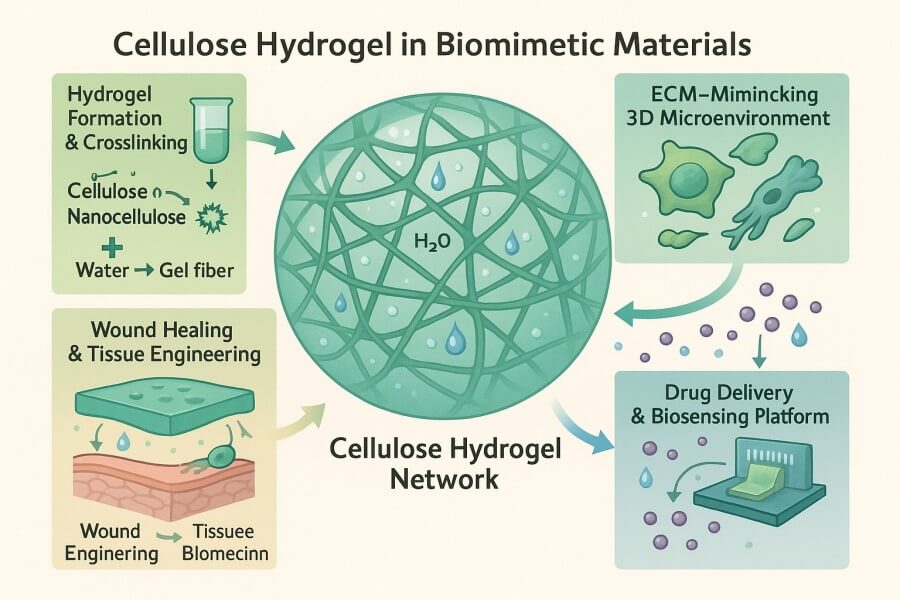

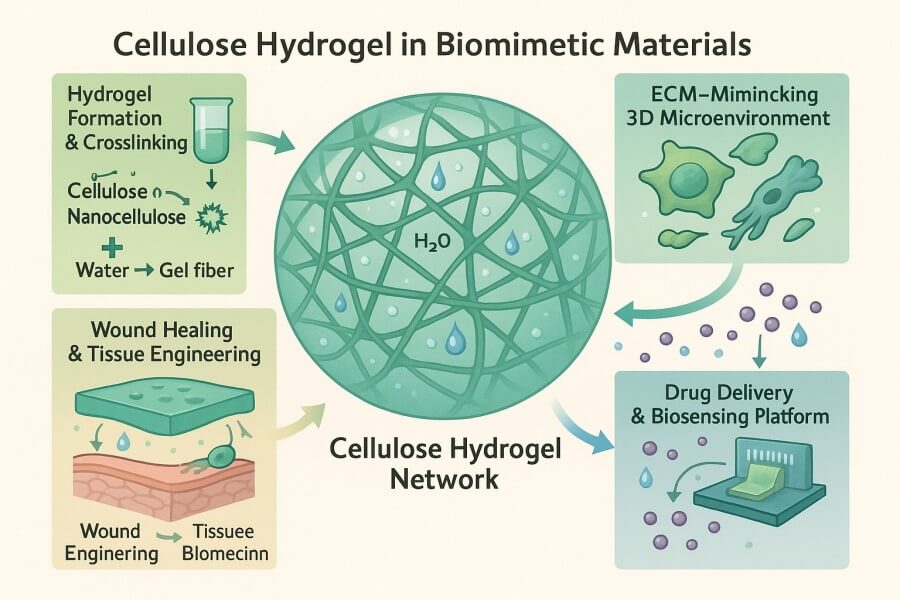

Cellulose Hydrogel Preparation

Cellulose hydrogel is a three-dimensional network hydrogel primarily composed of cellulose, formed through physical or chemical methods. These hydrogels can absorb large amounts of water while maintaining a solid-state structure and exhibit excellent biocompatibility and biodegradability. Hydrogels prepared from cellulose not only retain the environmentally friendly and renewable properties of cellulose but also gain unique functionalities such as water absorption, moisture retention, and responsiveness through their network structures. Compared with synthetic polymer hydrogels, cellulose hydrogels are natural, biodegradable, and can be chemically modified to achieve various functional applications, including drug delivery, tissue engineering scaffolds, and smart responsive materials. Leveraging its extensive biochemical expertise, BOC Sciences has long been committed to the customized preparation and development of cellulose hydrogels. We provide researchers, material developers, and manufacturers with full-process technical support, from raw material selection and formulation optimization to functional modification and scale-up production, ensuring efficient and reliable solutions throughout biomimetic material research and industrialization.

What We Offer

Cellulose Hydrogel Preparation Capabilities of BOC Sciences

Relying on a leading polymer chemistry R&D platform, extensive hydrogel preparation experience, and full-process customization capabilities, BOC Sciences provides clients with efficient and reliable solutions. Whether for fundamental research, functional development, pilot studies, or industrial-scale production, we ensure precise performance matching, structural optimization, and multifunctional customization, helping clients maintain a competitive edge in biomimetic materials.

Natural Cellulose Hydrogel

- High-purity raw material selection and solution preparation, ensuring structural stability and biodegradability.

- Physical crosslinking techniques to guarantee hydrogel biocompatibility.

- Customizable pore structure, thickness, and morphology (block, film, sheet, etc.).

- Supports development of basic water-absorbing materials, biomimetic tissue scaffolds, and environmentally friendly applications.

Cellulose Derivative Hydrogel

- Supports preparation of derivative hydrogels such as carboxymethyl cellulose (CMC), hydroxypropyl cellulose (HPC), and methyl cellulose (MC).

- Provides chemical crosslinking and functional modification technologies to control swelling and responsive properties.

- Enables development of smart hydrogels with pH, temperature, or ion responsiveness.

- Applicable for drug-controlled release carriers, smart biomimetic materials, and functional food carriers.

Nanocellulose Hydrogel (CNF)

- Offers nanofiber treatment, dispersion, and composite technologies to ensure uniformity and stability.

- Supports high-strength structural design and transparent hydrogel preparation.

- Customizable specific surface area and pore structure for enhanced mechanical performance.

- Applied in advanced composites, flexible electronics, soft robotics, and microfluidic systems.

Composite Cellulose Hydrogel

- Provides cellulose/derivative composite technologies with other polymers (chitosan, gelatin, polyacrylamide, etc.).

- Supports mechanical performance enhancement, pore structure optimization, and multifunctional design.

- Enables development of multi-responsive hydrogels and active molecule carriers.

- Suitable for smart materials, biomimetic functional carriers, and high-performance industrial applications.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Cellulose Hydrogel Synthesis and Development Services

BOC Sciences offers comprehensive cellulose hydrogel services, covering the full research-to-industrialization process, including raw material selection, formulation optimization, hydrogel preparation, and functional modification. Our services support both natural cellulose and various derivative hydrogels and provide functional solutions such as temperature-sensitive, pH-responsive, ion-responsive, and drug delivery systems, enabling performance customization and intelligent design.

1Raw Material Selection and Analysis

- Natural cellulose and derivative raw materials: High-purity cotton fibers, wood pulp fibers, carboxymethyl cellulose, hydroxypropyl cellulose, methyl cellulose, and more.

- Molecular weight and substitution analysis: For derivative hydrogels, we provide molecular weight, substitution degree, and functional group content analysis to ensure consistent and controllable hydrogel preparation.

- Solubility and solution property testing: Assess raw material solubility, viscosity, and rheological behavior under different solvents and pH conditions to support process optimization.

2Hydrogel Preparation and Formulation Optimization

- Physical crosslinking hydrogel preparation: Freeze-thaw, ionic crosslinking, and self-assembly methods suitable for food, cosmetics, and environmental materials.

- Chemical crosslinking hydrogel preparation: Aldehyde, epoxy, esterification, or amidation crosslinking methods to enhance mechanical properties and water resistance, applicable in biomedical fields.

- Composite hydrogel development: Combining cellulose with chitosan, gelatin, polyacrylamide, etc., to enhance functionality and mechanical performance.

- Process optimization services: Adjust formulation and crosslinking conditions based on water absorption, pore structure, and mechanical properties to achieve performance customization.

3Functional and Smart Modification

- Responsive hydrogel development: Temperature-sensitive, pH-sensitive, ion-sensitive, and light-responsive hydrogels for drug delivery and smart materials.

- Drug and nutrient release function: Load drugs, small-molecule nutrients, or bioactive molecules according to client needs for precise controlled release.

- Antibacterial and antioxidant functionalization: Impart hydrogel with antibacterial and antioxidant properties through nanoparticles or chemical modification, suitable for medical dressings and food protection materials.

4Scale-Up Production and Technology Transfer

- Laboratory to pilot-scale: Support from lab samples to pilot production, with batch process verification.

- Industrial-scale production solutions: Provide full-process technical guidance for solution preparation, crosslinking, drying, shaping, and packaging to support industrial translation.

- Multiple hydrogel formats: Block, sheet, film, microsphere, and injectable hydrogels to meet diverse application needs.

Characterization

Cellulose Hydrogel Analytical Platform

Through multidimensional characterization and testing, we comprehensively evaluate the chemical structure, physical performance, and functional properties of hydrogels. This provides a scientific basis for process optimization, formulation design, and performance customization. Combined with biocompatibility and stability analysis, we help clients develop and mass-produce high-quality hydrogels for pharmaceutical, food, and industrial applications.

| Test Category | Main Test Items | Methods and Description |

|---|

| Chemical Structure Analysis | Molecular Weight Determination | GPC and viscosity methods to analyze molecular weight and distribution of cellulose and its derivatives |

| Functional Group Content | FTIR and NMR analysis of hydroxyl, carboxyl, methoxy, and other functional groups |

| Crystallinity and Crystal Form | X-ray diffraction (XRD) to evaluate hydrogel crystallinity and structural changes |

| Microstructure Characterization | Porous Structure | SEM and TEM observation of pore size, morphology, and distribution within the hydrogel |

| Surface Properties | Contact angle measurement and specific surface area analysis to assess hydrophilicity and adsorption performance |

| Mechanical Properties Testing | Compression Strength & Elasticity | Universal testing machine to measure compressive, tensile, and elastic recovery performance |

| Viscoelasticity | Rheological testing to evaluate storage modulus, loss modulus, and responsive behavior |

| Water Absorption & Retention | Water Uptake and Swelling Ratio | Standard water absorption tests to assess hydrogel swelling speed, capacity, and expansion characteristics |

| Functional Performance Testing | Stimuli Responsiveness | Volume change and response rate under pH, temperature, ionic strength, or light stimuli |

| Controlled Release Performance | Release profile measurement and kinetic analysis of loaded drugs or bioactive molecules |

| Biological Performance Evaluation | Biocompatibility | Cytotoxicity assays (MTT, CCK-8) and cell adhesion observation |

| Degradability | Hydrogel degradation rate and by-product analysis under simulated physiological conditions |

Advantages

BOC Sciences Cellulose Hydrogel Service Advantages

- Professional Technical Team: Experienced chemical engineers and biochemistry experts proficient in the properties of cellulose and its derivatives, modification technologies, and hydrogel preparation processes.

- Multi-Type Cellulose Hydrogel Development: Supports development of natural cellulose hydrogels, cellulose derivative hydrogels (CMC, HPC, MC, etc.), nanocellulose hydrogels (CNF), and composite hydrogels.

- Full-Process Customization: Covers raw material selection, solution preparation, physical and chemical crosslinking, functional modification, and scale-up production to meet research, experimental, and industrial requirements.

- Flexible Delivery Scale: From milligram-level laboratory samples to kilogram or industrial-scale production, delivery can be tailored to client needs.

- Functional and Smart Modification: Offers temperature-sensitive, pH-responsive, ion-responsive, and drug-controlled release hydrogel solutions according to application requirements.

- Strict Quality Control: Employs multidimensional analysis—including molecular weight, crosslinking degree, water absorption, and mechanical performance—from raw materials to final products, ensuring stable and reliable hydrogel performance.

- Wide Industry Applicability: Services target biomimetic material researchers, pharmaceutical R&D institutes, functional food developers, and industrial manufacturers.

Service Process

Customized Cellulose Hydrogel Development Process

BOC Sciences provides a systematic, traceable development process to help clients achieve precise performance matching from concept design to mass production. Through scientific process management and stage-wise verification, we ensure that every batch of hydrogel meets client expectations in water absorption, mechanical performance, and functional properties.

1Requirement Analysis and Solution Design

At the project outset, BOC Sciences communicates closely with clients to define the hydrogel's application, performance specifications, and product form. Based on this information, we create a personalized development plan covering hydrogel type, functionalization strategies, and possible process routes to ensure alignment with client objectives.

2Raw Material Selection and Pre-Evaluation

We select the most suitable natural cellulose or cellulose derivatives based on specific hydrogel performance requirements and perform pre-evaluation of molecular weight, functional group content, and solubility. Scientific material screening ensures that the prepared hydrogel has a reliable foundation in physical, chemical, and functional performance.

3Formulation Design and Preparation Process

Combining raw material characteristics and client needs, we optimize hydrogel formulations, including crosslinking method, crosslinker concentration, and functional modification schemes. Preparation parameters such as solution concentration, temperature, and reaction time are also defined to ensure structural stability and controllable performance during hydrogel fabrication.

4Performance Optimization and Testing Verification

After preparation, BOC Sciences conducts multidimensional performance testing, including water absorption, pore structure, mechanical performance, and responsiveness. By repeatedly optimizing formulation and process parameters, we achieve precise alignment with client requirements, ensuring reproducibility and stability of research samples.

5Sample Delivery and Pilot Verification

Based on client needs, laboratory or pilot-scale samples are provided for verification. This stage focuses on performance confirmation, operational feasibility, and small-scale production validation, ensuring that hydrogel properties remain consistent during scale-up production and preparing for mass production.

6Scale-Up Production Support and Continuous Improvement

After pilot verification, BOC Sciences provides industrial-scale production support, including process optimization, equipment selection, and operational guidance. Continuous improvement plans and technical consulting ensure stable performance and reliable quality in large-scale production, meeting long-term application requirements.

Applications

Applications of Cellulose-Based Hydrogels in Biomimetic Materials

Cellulose-based hydrogels, with excellent hydrophilicity, biodegradability, and tunable mechanical properties, show broad potential in biomimetic material research. Their three-dimensional network and functionalization capabilities enable them to mimic natural biological tissue environments while meeting needs for drug delivery, smart responsiveness, and structural support. BOC Sciences' customized cellulose hydrogels support a wide range of biomimetic material solutions for research, development, and industrial applications.

Biomedical Biomimetic Materials

- Tissue Engineering Scaffolds: Provide three-dimensional support and growth space for cells, promoting soft tissue and bone regeneration.

- Drug-Controlled Release Carriers: Enable sustained release, targeted delivery, and combination drug administration to improve therapeutic outcomes.

- Wound Dressings and Care: High water absorption and biocompatibility for trauma repair and post-operative care.

- Injectable Hydrogels: Facilitate cell delivery, drug injection, and minimally invasive treatment, convenient for clinical use.

Food and Functional Material Biomimetic Applications

- Thickening and Stabilization: Adjust food texture, improve mouthfeel, and enhance water retention.

- Functional Food Carriers: Deliver probiotics, vitamins, or plant bioactives for controlled release protection.

- Low-Calorie Food Alternatives: Serve as fat replacers and improve texture for healthier food options.

- Smart Food Packaging: Hydrogel films respond to humidity or temperature changes to preserve food.

Environmental and Sustainable Materials

- Pollutant Adsorption and Treatment: Adsorb heavy metals, dyes, and organic pollutants for water purification.

- Biodegradable Packaging: Replace traditional plastics for environmentally friendly packaging solutions.

- Smart Responsive Materials: Temperature, pH, or light-responsive hydrogels for sensors and microfluidic systems.

- Enhanced Composite Functional Materials: Combine with nanocellulose or other polymers to improve mechanical strength and multifunctionality.

High-Performance Biomimetic Engineering Materials

- Flexible Electronics: Hydrogels as flexible substrates to support wearable devices.

- Soft Robotics Materials: Biomimetic hydrogels for actuating structures with controllable deformation.

- Microfluidic Systems: Serve as channel fillers or carrier materials for intelligent fluid control.

- Multi-Functional Responsive Composites: Combine light, electrical, and thermal responsiveness for complex functional designs.

FAQs

Frequently Asked Questions

-

What is cellulose hydrogel?

Cellulose hydrogel is a three-dimensional polymer network derived from natural or modified cellulose that can retain large amounts of water. It combines the biocompatibility, biodegradability, and mechanical strength of cellulose with high water absorption, making it suitable for biomedical, cosmetic, and industrial applications. Cellulose hydrogels are widely used in wound dressings, drug delivery, tissue engineering, and agriculture due to their swelling behavior and controlled release capabilities. Its unique structure allows it to interact with other molecules, making it a versatile material in both research and commercial products.

-

How to make cellulose gel?

Cellulose gel can be prepared through physical or chemical crosslinking methods. Common approaches include dissolving cellulose or cellulose derivatives in suitable solvents, followed by crosslinking with agents such as citric acid, epichlorohydrin, or metal ions like Ca²⁺. Regeneration techniques, such as coagulation in non-solvents, are also used to form hydrogel networks. The process can be tailored to adjust gel properties like porosity, mechanical strength, and swelling capacity. Advanced methods include blending with other polymers or incorporating nanoparticles to enhance functionality for biomedical, cosmetic, or industrial applications.

-

What are cellulose hydrogel properties?

Cellulose hydrogels exhibit high water absorption, biocompatibility, biodegradability, and structural stability. They have tunable mechanical strength, porosity, and swelling behavior depending on the cellulose source, derivative type, and crosslinking method. Other notable properties include gas permeability, thermal stability, and compatibility with bioactive molecules. These characteristics make cellulose hydrogels ideal for biomedical uses like wound dressings, tissue scaffolds, and drug delivery systems, as well as industrial applications such as water retention, enzyme immobilization, and cosmetic formulations.

-

What is the purpose of cellulose gel?

Cellulose gel serves multiple purposes across industries due to its water retention, biocompatibility, and structural versatility. In biomedical applications, it functions as a wound dressing, drug delivery system, or tissue scaffold. In cosmetics, cellulose gel provides moisturizing and stabilizing effects in creams and lotions. Industrially, it is used in water purification, agriculture for soil moisture retention, and as a carrier for enzymes or bioactive compounds. Its ability to swell, retain water, and form controlled-release systems makes cellulose gel a key material in research, development, and commercial applications.

-

What is bacterial cellulose hydrogel?

Bacterial cellulose hydrogel is a hydrogel formed from cellulose produced by certain bacteria, such as Gluconacetobacter xylinus, through fermentation. It shares a similar chemical structure with plant cellulose but exhibits unique properties due to microbial synthesis:

High purity and nanofiber structure: Free of lignin and hemicellulose, with nanometer-scale fibers forming a dense three-dimensional network.

Exceptional water absorption: Can retain dozens to hundreds of times its own weight in water while maintaining hydrogel form.

Excellent biocompatibility and biodegradability: Suitable for biomedical, tissue engineering, and food applications.

Superior mechanical properties: The nanofiber network provides good tensile strength and flexibility, resisting deformation without breaking.

Functionalization potential: Can be chemically or physically modified for drug loading, smart responsiveness, or composite material development.

Applications include wound dressings, tissue engineering scaffolds, drug delivery carriers, and food thickeners.

-

What is carboxymethyl cellulose hydrogel?

Carboxymethyl cellulose (CMC) hydrogel is a chemically modified cellulose derivative crosslinked to form a water-absorbing gel. It exhibits high swelling capacity, biocompatibility, and stability, making it suitable for biomedical, pharmaceutical, and cosmetic applications. CMC hydrogels can be tailored by adjusting the degree of substitution or crosslinking density, enabling controlled drug release, wound healing, and tissue engineering. Its ease of preparation and ability to interact with other polymers or nanoparticles makes it a versatile material for research and industrial applications.

-

What is cellulose acrylamide hydrogel?

Cellulose acrylamide hydrogel is a hybrid material synthesized by grafting acrylamide onto cellulose chains, creating a network with enhanced water absorption and mechanical properties. It combines the biodegradability and biocompatibility of cellulose with the tunable properties of synthetic polymers. This hydrogel is widely used for controlled drug delivery, tissue scaffolds, wound healing, and water retention in agriculture. Its structure can be customized to adjust swelling, porosity, and responsiveness to pH or temperature, making it suitable for both biomedical and industrial applications.

-

What is a cellulose hydrogel scaffold?

A cellulose hydrogel scaffold is a three-dimensional network designed to support cell attachment, growth, and tissue regeneration. Made from natural or modified cellulose, it provides a biocompatible and biodegradable environment for cells. Its porous structure allows nutrient and oxygen diffusion while enabling controlled release of bioactive molecules. Cellulose hydrogel scaffolds are widely used in tissue engineering, regenerative medicine, and wound healing studies, offering customizable mechanical and swelling properties to mimic natural extracellular matrices and enhance functional tissue development.

-

How are cellulose hydrogels used for drug delivery?

Cellulose hydrogels are used for drug delivery due to their high water absorption, biocompatibility, and tunable network structure. Drugs can be loaded into the hydrogel matrix and released in a controlled manner, responding to pH, temperature, or enzymatic conditions. They protect sensitive molecules, prolong therapeutic effects, and reduce side effects. Carboxymethyl cellulose, bacterial cellulose, and cellulose-acrylamide hydrogels are commonly used in oral, transdermal, and injectable formulations, providing versatile platforms for sustained and targeted drug delivery in pharmaceutical and biomedical applications.