Polyurethane Fiber Preparation

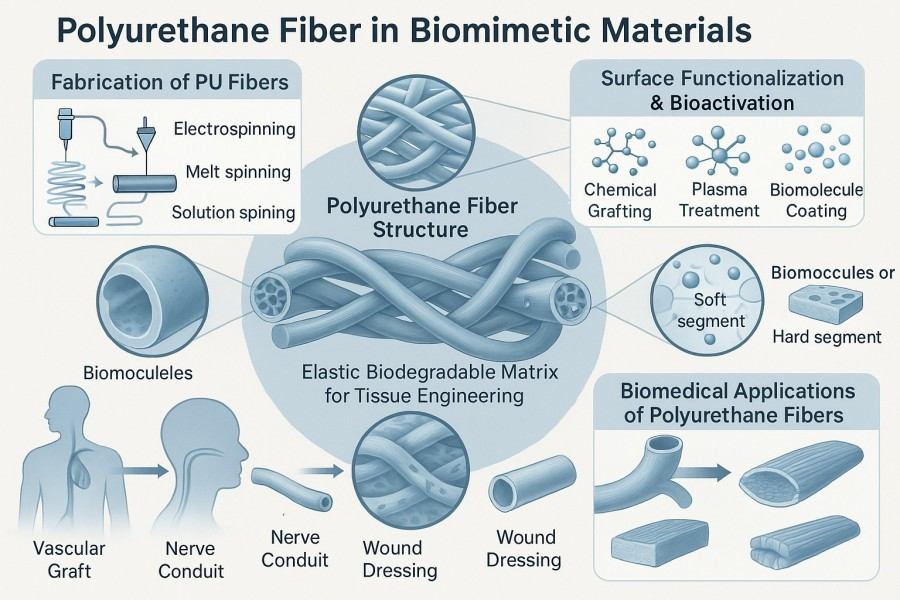

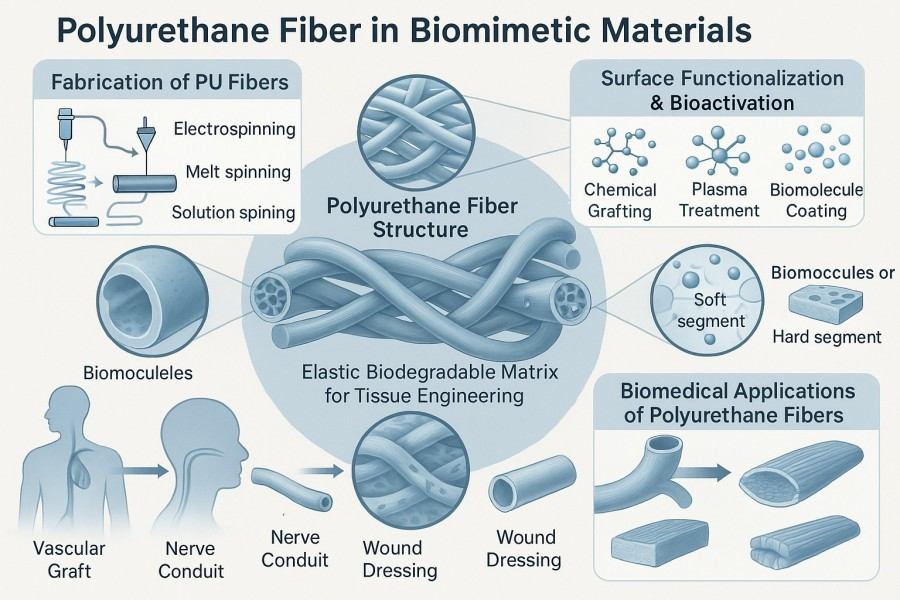

Polyurethane fibers, also known as elastic fibers or Spandex, are high-molecular-weight synthetic materials composed of polyurethane (PU) elastomers. Their unique chemical structure originates from the microphase separation between soft segments (flexible polyether or polyester polyols) and hard segments (rigid components containing diisocyanates and chain extenders), which endows the material with excellent elasticity, good resilience, tunable biocompatibility, and adjustable mechanical properties. Compared with traditional synthetic fibers, polyurethane fibers combine the elasticity of rubber with the processability of plastics. They can be fabricated into fibers of various diameters, structures, and forms through solution spinning, electrospinning, melt spinning, and other methods. These fibers are widely used in biomimetic materials, biodegradable medical devices, drug delivery systems, and functional tissue scaffolds. BOC Sciences focuses on polymer chemistry and biomaterials technology R&D, providing integrated solutions from molecular design, material preparation, performance tuning, functional validation, to pilot-scale production. Leveraging years of experience in PU synthesis and modification, we can customize PU fibers with tailored performance specifications, offering full-process support from fundamental research to industrial applications.

What We Offer

PU Fibers Offered by BOC Sciences

BOC Sciences customizes various types of polyurethane fibers according to different biomedical and functional requirements. We provide PU fibers with precise structures and controllable properties for biomimetic materials, medical devices, and drug delivery systems, ensuring an optimal balance between mechanical strength, biocompatibility, and functional responsiveness.

Solid PU Fibers

Solid PU fibers feature excellent mechanical strength and fatigue resistance, suitable for implantable medical devices, sutures, and elastic support structures. By adjusting the soft-to-hard segment ratio, their elastic modulus and resilience can be flexibly tuned to meet different load or deformation requirements.

Hollow PU Fibers

Hollow structures give PU fibers lightweight, porous, and controllable permeability characteristics, making them ideal for blood purification membranes, drug-controlled release carriers, and inner-layer support of artificial blood vessels. BOC Sciences can design inner diameter, wall thickness, and porosity according to mass transfer requirements, enabling precise delivery of drugs or nutrients.

Porous PU Fibers

Porous PU fibers are prepared via phase separation or solvent evaporation techniques, offering excellent breathability and cell adhesion. They are commonly used in tissue engineering scaffolds, skin repair substrates, and biodegradable medical dressings. Pore size distribution, specific surface area, and degradation rate can be tailored to application needs.

Composite PU Fibers

By combining polyurethane with inorganic nanomaterials (e.g., HA, SiO₂, GO) or biopolymers (e.g., collagen, chitosan, PLA), BOC Sciences can produce PU composite fibers with high mechanical strength, conductivity, or bioactivity, widely applied in bone tissue engineering, flexible sensors, and multifunctional medical scaffolds.

Functionalized PU Fibers

BOC Sciences offers various surface modification and functionalization strategies, including antibacterial, anti-inflammatory, conductive, thermo-sensitive, or pH-responsive modifications, providing smart-responsive properties. In drug delivery systems, functionalized PU fibers enable environment-triggered drug release, while in biomimetic materials and medical devices, they enhance cell compatibility and anti-fouling performance.

Electrospun PU Nanofibers

Electrospun PU nanofibers form networks that closely mimic natural extracellular matrix (ECM), effectively promoting cell adhesion and growth. These fibers demonstrate superior biomimetic performance and biocompatibility in nerve regeneration, vascular tissue engineering, and drug release systems. BOC Sciences can control fiber diameter, alignment, and porosity by adjusting electrospinning parameters.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Technical & Project Support for Polyurethane Fibers

BOC Sciences is committed to providing comprehensive technical support for the research and application of polyurethane fibers. We understand that biomimetic materials, medical devices, and drug delivery systems require strict control over material performance, structural precision, and biocompatibility. Our multidimensional service system covers molecular design, fiber fabrication, performance characterization, and functional validation. Whether for scientific exploration or product development, BOC Sciences delivers efficient, customizable solutions.

1Molecular & Formulation Design

We provide customized PU system design at the molecular level to ensure precise alignment between material performance and application requirements.

- Design of polyether, polyester, and polycarbonate polyol systems to achieve different flexibility and biodegradation rates.

- Optimization of diisocyanates and chain extenders to control fiber elastic modulus, thermal stability, and mechanical strength.

- Introduction of functional monomers to impart conductivity, antibacterial properties, or stimuli responsiveness to PU fibers.

- Development of biodegradable/implantable-grade formulations compliant with medical material safety standards.

2Fiber Fabrication & Morphology Control

BOC Sciences has multi-platform fiber fabrication capabilities, allowing precise control of fiber structure, size, and orientation for target applications.

- Electrospinning, solution spinning, and melt spinning platforms for nanoscale to microscale fiber production.

- Adjustable porosity, diameter, and surface roughness for cell scaffolds or controlled-release systems.

- Construction of hollow, porous, and composite fiber structures to enhance mechanical properties and mass transfer.

- Pilot-scale production from lab to semi-industrial scale to support both research and industrial applications.

3Material Characterization & Biocompatibility Testing

To ensure PU fiber safety and stability in biological systems, we offer comprehensive material analysis and biological evaluation services.

- Physicochemical analysis: FTIR, NMR, GPC, DSC, TGA, SEM, and more for structural and thermal performance characterization.

- Mechanical testing: tensile strength, elasticity recovery, and fatigue testing to ensure material stability.

- Biocompatibility evaluation: cell adhesion, proliferation, and cytotoxicity assays to verify tissue compatibility.

- Degradation and release studies: long-term performance and drug release kinetics under simulated physiological conditions.

4Functionalization & Application Validation

BOC Sciences not only provides basic fiber fabrication but also assists customers in the complete development process from functionalization to application validation.

- Surface modification and functional coating technologies to achieve antibacterial, anti-inflammatory, conductive, or targeted-release functions.

- Strategies for drug or bioactive molecule loading to support sustained and stimuli-responsive release system design.

- Biomimetic application testing: verification of mechanical response and biological integration under simulated tissue environments.

- Customized project collaboration: support for the development and industrial scaling of novel medical PU fiber products.

Advantages

Why Choose BOC Sciences: Service Benefits Explained

- Extensive Technical Expertise: Equipped with leading polyurethane synthesis and modification technology platforms, supporting the R&D of various polyether, polyester, and composite PU systems, ensuring precise control over fiber performance.

- Integrated Full-Process Capability: Covering the complete technical chain from molecular design, fiber fabrication, performance characterization to pilot-scale production, providing end-to-end support for both research and industrial clients.

- Multidimensional Fabrication and Characterization Platforms: Equipped with electrospinning, solution spinning, and melt extrusion systems, along with advanced characterization tools such as FTIR, SEM, GPC, and DSC.

- Customized Support for Specialized Fields: Offering targeted material design and performance optimization solutions for biomimetic materials, medical devices, and drug delivery systems, meeting specific application requirements.

- Strict Quality and Compliance System: Implementing comprehensive quality control and traceability management throughout the process to ensure safety and reliability at medical and biomaterial-grade standards.

- Rapid Response and Collaboration Mechanism: Dedicated project teams provide efficient communication, fast solution adjustments, and flexible customization, shortening R&D cycles and improving delivery efficiency.

- Global Customer Support Network: Offering technical consultation, sample validation, and ongoing after-sales support worldwide, facilitating efficient translation from laboratory research to industrial applications.

Service Process

Polyurethane Fiber Customization: Workflow and Procedures

BOC Sciences has established a systematic and efficient workflow for PU fiber R&D and manufacturing. We provide professional support at every stage, from material design to product validation, ensuring high-quality and consistent project advancement. This seamless process supports customers in biomimetic materials, medical devices, and drug delivery systems, enabling smooth translation from experimental research to practical applications.

1Requirement Communication & Project Planning

BOC Sciences conducts in-depth discussions with clients to fully understand project background, application scenarios, and performance requirements, such as mechanical properties, degradation rate, or drug loading capacity. Combining technical feasibility with industry experience, we develop rational development routes and project plans, defining key performance indicators to ensure orderly R&D progression aligned with practical application goals.

2Material Design & Solution Development

Based on client needs, we design polyurethane systems at the molecular level, selecting appropriate polyols, diisocyanates, and chain extenders. By optimizing soft-to-hard segment ratios and introducing functional groups, we precisely tune fiber elasticity, thermal stability, degradation rate, and biocompatibility. The design plan covers fiber structure, porosity, and surface functionalization, providing a scientific basis for subsequent fabrication and applications.

3Laboratory Fabrication & Preliminary Validation

At the laboratory stage, BOC Sciences prepares sample fibers using electrospinning, solution spinning, or melt extrusion techniques. Fibers undergo preliminary performance evaluation, including diameter distribution, pore structure, mechanical properties, and surface morphology. Small-scale experiments validate material feasibility, providing data for further optimization and functionalization to ensure alignment with client expectations.

4Performance Characterization & Functional Optimization

Comprehensive performance characterization is conducted on the prepared fibers, covering physical, chemical, and biological metrics. Tests include mechanical strength, elastic modulus, thermal stability, degradation behavior, and cell compatibility. Based on results, fibers are functionally optimized, such as surface grafting with antibacterial agents or drug loading, achieving smart responsiveness or specific functionality suitable for biomimetic applications and medical device requirements.

5Application Testing & Process Scale-Up

Application validation is performed in biomimetic materials, medical devices, or drug delivery scenarios, including cell culture, drug release studies, and mechanical simulation. Fiber structure and fabrication processes are optimized based on validation results, followed by pilot-scale production to ensure batch consistency and reproducibility, providing directly translatable technical solutions for research projects or product development.

6Final Delivery & Technical Support

After pilot or small-batch production, BOC Sciences provides complete performance reports and application recommendations, including material properties, usage instructions, and optimization guidance. Continuous technical support and follow-up collaboration are offered, covering process improvement, functional optimization, and scale-up production, ensuring smooth application in biomimetic materials, medical devices, and drug delivery projects.

Applications

Medical and Industrial Applications of Polyurethane Fibers

Due to their excellent elasticity, tunable mechanical properties, biocompatibility, and ease of functionalization, polyurethane fibers show broad potential in high-end applications such as biomimetic materials, medical devices, drug delivery, and wearable or smart functional materials. BOC Sciences offers customized PU fiber solutions to help research institutions and enterprises achieve precise matching between material performance and application functionality, accelerating the translation from laboratory research to practical use.

Biomimetic Materials

- PU fibers can mimic natural extracellular matrix (ECM) through electrospinning or porous structures, suitable for soft tissue scaffolds, nerve regeneration, and vascular engineering.

- Composite fibers combined with collagen, hydroxyapatite, or other biopolymers and inorganic nanomaterials enhance mechanical properties and bioactivity.

- Smart-responsive fibers can sense environmental stimuli (temperature, pH, or humidity) and adapt accordingly, achieving biomimetic self-regulating functions.

Medical Devices

- Suitable for implantable catheters, artificial blood vessels, surgical sutures, and wound dressings, offering excellent biocompatibility and controlled degradability.

- Functionalized surfaces provide antibacterial, anti-inflammatory, or blood-compatible properties, improving device safety and longevity.

- Elastic fibers can mimic soft tissue mechanics, enhancing device comfort and stability.

Drug Delivery Systems

- Porous or nanofiber structures serve as drug release carriers, enabling sustained or environmentally responsive drug release.

- Fibers can load small-molecule drugs, proteins, or growth factors for localized or targeted delivery, improving therapeutic efficacy.

- Functionalized fibers can respond to external stimuli (e.g., enzymes, pH, or temperature) to regulate drug release rates, minimizing side effects and enhancing precision therapy.

Wearable & Smart Functional Materials

- PU fibers can be used to create flexible sensors, pressure/strain monitoring materials, and smart textiles, adapting to human motion tracking and health monitoring.

- Functionalized fibers can integrate conductivity, temperature, or humidity responsiveness for intelligent adaptive functions.

- Combined with biomimetic design, fibers can form stretchable, bendable, and contractible smart materials, widely applied in wearable medical devices and electronic textiles.

FAQs

Frequently Asked Questions

-

What is polyurethane fiber?

Polyurethane fiber is a synthetic polymer fiber made from polyurethane, characterized by high elasticity, flexibility, and mechanical resilience. In advanced applications, its molecular tunability allows integration of bioactive, conductive, or stimuli-responsive components, making it suitable for biomimetic, medical, and smart material applications.

-

Is polyurethane a fiber?

Polyurethane itself is a polymer, not a fiber. However, it can be processed into fibers such as spandex (elastane), which are flexible and stretchable. In high-tech applications, PU fibers are engineered at the micro- or nanoscale to mimic tissue mechanics, wearable elasticity, or drug-release profiles.

-

Is polyurethane a synthetic fiber?

Yes. Polyurethane fibers are fully synthetic, produced from chemical monomers (diisocyanates and polyols). Their synthetic nature allows precise control over mechanical, chemical, and biological properties, essential for biomimetic scaffolds, implantable devices, and responsive textiles.

-

What are the medical uses of polyurethane fiber?

Biomimetic materials: PU fibers mimic natural tissue elasticity and resilience, making them ideal for soft tissue engineering scaffolds, artificial muscles, and flexible organ models. Their tunable stiffness and elasticity can replicate ligament, cartilage, or skin mechanics.

Medical devices: PU fibers are used in catheters, vascular grafts, wound dressings, and surgical meshes, where biocompatibility, flexibility, and durability are critical. Their elasticity reduces tissue irritation and enhances patient comfort.

Drug delivery systems: PU fibers can be functionalized or formed into microspheres, nanofibers, or composite membranes for controlled drug release. Their polymeric network allows encapsulation of drugs, growth factors, or nanoparticles, providing sustained and targeted delivery.

-

How are polyurethane fibers made for these advanced applications?

Polymer synthesis: Diisocyanates react with polyols to form PU prepolymers, sometimes with bioactive, conductive, or degradable segments.

Fiber formation: Prepolymers are processed via solution spinning, electrospinning, or melt spinning to produce micro- or nanofibers.

Functionalization: Fibers are further modified by surface coating, drug loading, or embedding nanoparticles.

Post-processing: Fibers are drawn, crosslinked, or assembled into scaffolds, membranes, or smart textiles to achieve desired elasticity, strength, and responsiveness.

-

Is polyurethane fiber biodegradable?

Conventional PU fibers are not readily biodegradable, but for medical and biomimetic uses, biodegradable PU variants can be designed with ester or polycaprolactone segments, allowing controlled degradation in tissue or physiological environments, which is critical for temporary scaffolds and drug delivery systems.