Gelatin Scaffold Preparation

Gelatin scaffolds are three-dimensional porous structures constructed from the natural polymer gelatin, designed to mimic the extracellular matrix (ECM) and provide a supportive environment for cells. Gelatin, derived from the partial hydrolysis of collagen, possesses excellent biocompatibility, biodegradability, and low immunogenicity, making it widely applied in tissue engineering, regenerative medicine, drug delivery systems, and biosensors. The primary function of gelatin scaffolds is to provide cells with a 3D support structure resembling in vivo tissues, promoting cell adhesion, proliferation, and differentiation. Compared with traditional two-dimensional cultures, 3D gelatin scaffolds more accurately simulate the physiological microenvironment, enhancing tissue engineering outcomes. BOC Sciences' gelatin scaffold preparation and development services provide comprehensive support for research institutions, medical device companies, and biopharmaceutical enterprises, covering material design, functional modification, and performance optimization, helping clients achieve breakthroughs in biomimetic materials and tissue engineering. Our services include various types of gelatin scaffolds, including PLGA-gelatin scaffold, gelatin-alginate scaffolds and gelatin-hydroxyapatite scaffolds. By integrating chemical crosslinking, 3D bioprinting, nanocomposites, and functional modification techniques, BOC Sciences offers customized biomimetic solutions to meet the precise requirements of tissue engineering and controlled drug delivery applications.

What We Offer

Comprehensive Gelatin Scaffold Preparation Solutions

At BOC Sciences, we provide a diverse range of gelatin scaffolds to meet the needs of tissue engineering, regenerative medicine, and drug delivery research. Whether scaffolds are combined with alginate, hydroxyapatite, or PLGA, or modified for functional or responsive properties, we offer tailored design, preparation, and performance optimization services aligned with your research goals. By precisely controlling porosity, mechanical properties, and bioactivity, we ensure each gelatin scaffold provides an ideal environment for cell growth while supporting drug release or bioactive functionality.

Gelatin-Alginate Scaffold

- Customizable gelatin/alginate ratios to control porosity and mechanical performance according to client requirements.

- Supports porous structure design to enhance cell adhesion and migration.

- Offers bioactive modification, capable of loading growth factors or signaling molecules.

- Compatible with drug or nanoparticle incorporation for controlled release or functional applications.

Gelatin-Hydroxyapatite Scaffold

- Provides various gelatin/hydroxyapatite composite formulations to simulate bone tissue microenvironments.

- Customizable pore size, porosity, and mechanical properties for bone tissue engineering needs.

- Functional modifications available, such as loading osteoinductive factors or antibacterial agents.

- Performance analysis services, including mechanical testing, degradation rate, and biocompatibility assessment.

PLGA-Gelatin Scaffold

- Customizable PLGA/gelatin ratios to control scaffold degradation rate and mechanical properties.

- Supports multiple fabrication methods, including 3D printing and freeze-drying.

- Drug loading and controlled release design services available.

- Can incorporate bioactive molecules for tissue engineering or drug delivery applications.

Functionalized Gelatin Scaffold

- Growth factor, cell adhesion peptide, or antibacterial molecule modification services.

- Supports responsive modifications, such as pH-, temperature-, or light-triggered release designs.

- Capable of drug or protein loading for long-term controlled or targeted release.

- Custom scaffold structure design to optimize cell proliferation and differentiation environments.

Composite Gelatin Scaffold

- Combined with nanomaterials (e.g., hydroxyapatite, nanocellulose) to enhance mechanical properties.

- Capable of loading drugs or growth factors for multifunctional biomimetic scaffolds.

- Supports smart responsive modifications, including temperature, pH, or light responsiveness.

- Can be combined with 3D printing for customized development of complex tissue engineering structures.

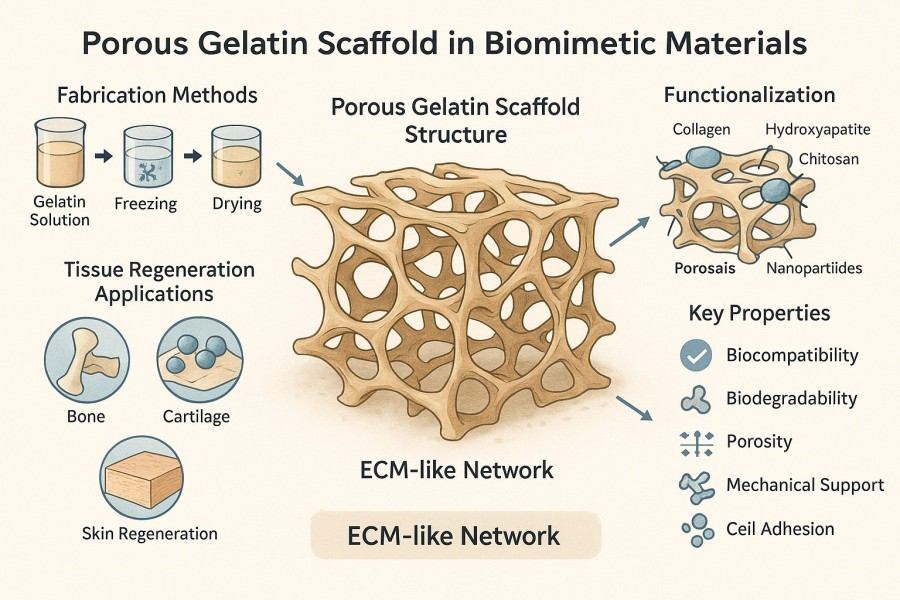

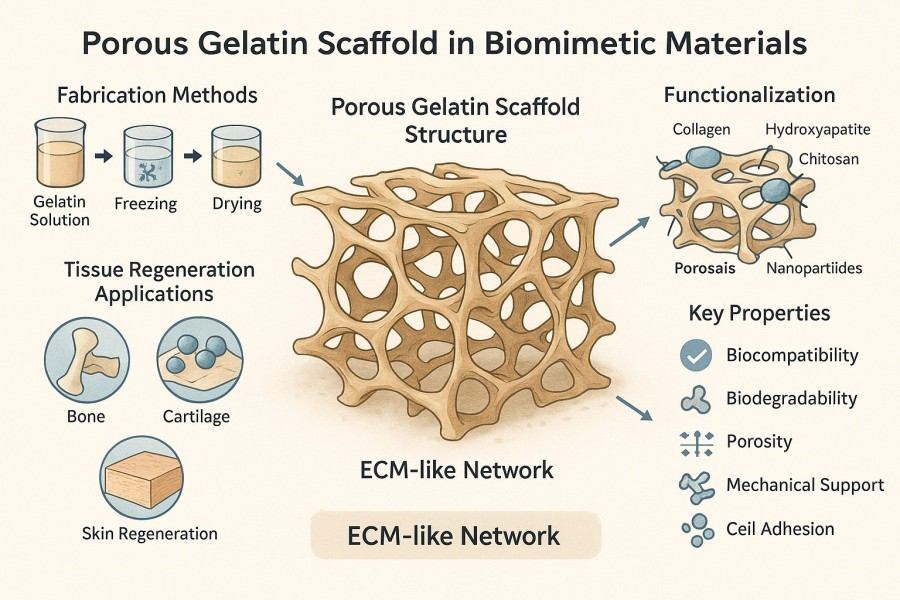

Porous Gelatin Scaffold

- Offers scaffolds with adjustable porosity to suit diverse tissue engineering needs.

- Customizable pore size distribution to ensure cell adhesion, migration, and angiogenesis.

- Supports chemical crosslinking and composite modification to enhance mechanical strength and degradation control.

- Drug loading and controlled release development to meet precise therapeutic requirements.

Fibrous Gelatin Scaffold

- Provides nanometer-to-micrometer fiber scaffolds that mimic natural ECM structures.

- Fiber diameter and alignment can be adjusted to guide directional cell growth.

- Supports functional modification, such as RGD peptide functionalization or growth factor loading.

- Combines electrospinning or 3D printing technologies to provide composite fibrous scaffold solutions.

Sponge Gelatin Scaffold

- Soft, sponge-like scaffolds with high water absorption, suitable for soft tissue repair.

- Adjustable pore structure to provide a uniform cell growth environment.

- Supports drug or protein loading for controlled release functionality.

- Chemical or physical crosslinking can optimize mechanical properties and degradation rate.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Gelatin Scaffold Preparation and Customization Services

To meet diverse application needs, BOC Sciences offers comprehensive gelatin scaffold preparation and development services, covering the full workflow from material design, fabrication methods, functional modifications, to performance analysis and optimization. Whether you require support for basic research, complex tissue engineering models, or custom drug delivery platforms, we provide professional, tailored solutions to help clients achieve efficient results in biomedical applications of gelatin scaffolds. Our services mainly include:

1Material Selection and Design

- Selection of various gelatin types (Type A, Type B, GelMA) to ensure scaffold base materials meet biocompatibility and degradation requirements.

- Can be combined with various polymers, such as PLGA, alginate, or hydroxyapatite.

- Molecular design services to tune scaffold porosity, pore distribution, and mechanical properties for optimal match with target tissues.

- Scaffold chemical structure and composite ratios can be optimized to support functional modifications or drug loading.

2Gelatin Scaffold Fabrication Methods

- Freeze-Drying: Produces highly porous scaffolds suitable for bone, cartilage, and soft tissue engineering, providing uniform pores and favorable cell growth environments.

- Electrospinning: Creates nano/microfiber network scaffolds mimicking natural ECM structures, enhancing cell adhesion and directional growth.

- Cross-Linking: Chemical or physical crosslinking enhances mechanical strength and degradation stability, suitable for long-term tissue repair applications.

- 3D Bioprinting: Supports custom scaffold designs with complex structures and internal channels for personalized tissue engineering needs.

3Functional Modification Services

- Bioactive modification: Incorporation of growth factors, cell adhesion peptides (e.g., RGD sequences), or antibacterial agents to enhance scaffold performance.

- Drug loading and controlled release: Scaffolds can carry small molecules, proteins, or signaling molecules for precise or sustained release.

- Composite development: Gelatin can be combined with nanoparticles, PLGA, hydroxyapatite, or alginate to improve scaffold mechanics, conductivity, or bone integration.

- Smart responsive modification: pH-, temperature-, or light-responsive scaffolds can be developed for dynamic control of drug release or cell behavior.

4Performance Analysis and Optimization

- Comprehensive gelatin scaffold characterization, including porosity, pore distribution, mechanical properties, degradation rate, and cell compatibility tests.

- Optimization of scaffold structure, formulation, or composite combinations based on performance results to meet tissue engineering or biomedical application needs.

- Custom performance tuning for different scenarios, such as bone tissue, cartilage repair, or drug delivery systems.

- Provision of experimental reports and technical guidance to accelerate R&D iteration and product optimization.

Characterization

Gelatin Scaffold Structural and Performance Analysis

BOC Sciences has extensive experience in polymer and biomaterial analysis, providing comprehensive analysis and quality assurance services for gelatin scaffolds. From structural characterization and mechanical evaluation to biocompatibility and degradation testing, we ensure that each batch of scaffolds meets research and industrial standards in performance, stability, and safety, offering reliable support for tissue engineering and biomimetic material projects.

| Test Category | Test Item | Service Capabilities |

|---|

| Physical Properties | Porosity Analysis | Measure scaffold porosity using liquid displacement or micro-CT scanning to ensure space for cell growth and nutrient transport. |

| Pore Size Distribution | Determine the proportion of different pore sizes; customize pore design to optimize tissue engineering outcomes. |

| Surface Morphology | Characterize scaffold fiber structure, pore shape, and surface roughness using SEM, AFM, etc. |

| Chemical Properties | Composition Analysis | Analyze gelatin and composite material components with FTIR, NMR, or XRD to ensure accurate material ratios. |

| Crosslinking Degree | Determine chemical or physical crosslinking levels to control mechanical strength and degradation rate. |

| Mechanical Properties | Compression/Tensile Testing | Measure scaffold compressive and tensile strength to meet target tissue load requirements. |

| Elastic Modulus | Provide mechanical simulation data to support design for different tissue engineering applications. |

| Biological Properties | Cell Compatibility | Evaluate scaffold biocompatibility through in vitro cell adhesion, proliferation, and differentiation assays. |

| Bioactivity Assessment | After functional modification, assess growth factor release rate and biological activity. |

| Degradation Properties | Hydrolytic/Enzymatic Degradation Rate | Simulate in vivo degradation environment and provide scaffold degradation curves under different conditions. |

| Controlled Degradation Optimization | Optimize crosslinking degree or composite ratios based on testing results to achieve custom degradation rates. |

Advantages

Top Features and Benefits of Gelatin Scaffold Services

- Customized Solutions: Based on clients' research goals and application needs, we provide highly personalized gelatin scaffold design and development solutions. Material formulations, structures, and functionalities can be precisely controlled to deliver full-process customization for each project.

- Multi-Process Fabrication Capability: We support multiple fabrication techniques, including freeze-drying, electrospinning, crosslinking, and 3D printing, meeting diverse research and industrial application requirements for tissue engineering, drug delivery, and in vitro cultures.

- Functional Modification Services: We offer bioactive modifications, drug loading, composite material development, and responsive modifications, enhancing scaffold functionality in cell adhesion, tissue regeneration, and controlled drug delivery.

- Performance Analysis and Optimization: Comprehensive testing of scaffold mechanical properties, porosity, degradation rate, and biocompatibility is conducted, with optimization solutions provided to ensure every batch meets research and industrial standards.

- Advanced Analysis and Quality Assurance: We deliver full-scale scaffold performance analysis, including porosity, mechanical strength, degradation rate, and cell compatibility testing, ensuring each gelatin scaffold batch is stable, reliable, and meets scientific and industrial application standards.

- Professional Technical Team: Our expert team in biomaterials and polymer chemistry combines extensive experimental and engineering experience to provide efficient, reliable technical support and R&D solutions for client projects.

- Extensive Application Experience: Our services cover tissue engineering, regenerative medicine, drug delivery, 3D in vitro cell culture, and biosensor development, accumulating rich experience in application cases and custom scaffold development.

- Fast Delivery and Flexible Services: Leveraging an efficient R&D and production system, we provide rapid delivery capabilities and can flexibly adjust fabrication processes and functionalization strategies according to project needs, supporting multi-stage research and industrial applications.

Service Process

Step-by-Step Workflow of Gelatin Scaffold Services

At BOC Sciences, we are committed to providing clients with efficient and systematic gelatin scaffold support services. Our workflow covers the entire process, from initial consultation to final delivery, ensuring each step meets scientific and industrial standards. Through scientific methodology and professional team support, we assist clients in custom scaffold design, functional development, and performance optimization, accelerating progress in tissue engineering and biomedical projects.

1Project Consultation and Needs Assessment

- Communicate with clients regarding research goals, application scenarios, and technical requirements.

- Provide feasibility assessments and preliminary proposals to ensure scientific and reasonable project direction.

- Define material types, scaffold performance, and functionalization needs as a foundation for custom development.

2Material Selection and Formulation Design

- Choose gelatin types (Type A, Type B, GelMA, etc.) and composite materials (PLGA, alginate, hydroxyapatite) based on application needs.

- Design scaffold porosity, mechanical properties, and degradation rates.

- Provide personalized material combinations to meet research and clinical application requirements.

3Gelatin Scaffold Fabrication

- Utilize freeze-drying, electrospinning, crosslinking, or 3D printing methods.

- Adjust process parameters according to scaffold type and intended use to ensure uniform structure and stable performance.

- Functional modifications or composite integration can be performed simultaneously.

4Functional Modification and Optimization

- Offer bioactive modification, drug loading, and nanoparticle composite services.

- Develop responsive release or specific biological signal functionalities.

- Optimize scaffold performance and material ratios based on preliminary testing results.

5Performance Analysis and Quality Control

- Conduct comprehensive testing of scaffold mechanical properties, porosity, degradation rate, and cell compatibility.

- Provide experimental reports and technical guidance to ensure scaffold performance meets project requirements.

- Offer customized performance optimization and multi-batch quality assurance.

6Delivery and Post-Support

- Provide customized gelatin scaffold samples and batch product delivery services.

- Offer technical support and usage guidance for efficient application in research or production.

- Continuously optimize solutions based on client feedback, supporting long-term collaboration and project iteration.

Applications

Applications of Gelatin Scaffolds in Biomimetic Materials

Gelatin scaffolds serve as a foundational material in biomimetic research and applications due to their excellent biocompatibility, degradability, and tunable physicochemical properties. By rationally designing scaffold porosity, mechanical properties, and functional modifications, gelatin scaffolds can mimic natural tissue microenvironments, supporting cell growth, differentiation, and functional expression. Typical applications in key biomimetic material fields include:

Tissue Engineering

- Provide 3D support structures to simulate the in vivo ECM microenvironment.

- Customizable porosity, pore size, and mechanical properties for soft tissue, bone, or cartilage engineering.

- Bioactive modifications, such as growth factor loading, to enhance cell adhesion, proliferation, and differentiation.

- Composite with nanoparticles or other polymers to improve mechanical strength and bone integration.

Drug Delivery Systems

- Scaffold can carry drugs, proteins, or signaling molecules for long-term controlled release.

- Pore structure and crosslinking can regulate drug release rate for targeted or timed delivery.

- Supports composite material development to enhance drug stability and release performance.

- Compatible with responsive functionalization for pH-, temperature-, or light-triggered drug release.

In Vitro Cell Culture

- Provides a 3D growth environment closer to physiological conditions than traditional 2D cultures.

- Customizable porosity and scaffold structure optimize cell distribution and nutrient transport.

- Surface modifications with cell adhesion peptides or growth factors enhance adhesion and differentiation.

- Suitable for stem cell culture, tumor model construction, and organ-on-chip research.

Biosensors

- Acts as a carrier to support functional molecules, enabling signal transduction in biosensors.

- Scaffold porosity and surface chemistry can regulate sensitivity and response speed.

- Composite with nanoparticles or conductive materials enhances detection signal and stability.

- Applicable to environmental monitoring, in vitro diagnostics, and real-time biosignal detection.

Regenerative Medicine

- Mimics damaged tissue microenvironments to support repair and regeneration.

- Can load growth factors, stem cells, or drugs to promote tissue repair and functional recovery.

- Scaffold degradation rate can be tuned to match tissue regeneration for gradual replacement.

- Applicable to bone, cartilage, skin, and vascular regeneration.

Wound Healing and Skin Regeneration

- Used for acute and chronic wound repair, mimicking skin tissue microenvironments.

- Capable of loading antibacterial molecules, stem cells, or growth factors to promote healing.

- Adjustable pore structure and degradation rate enable staged tissue regeneration.

- Combined with composites to enhance mechanical strength and biocompatibility, supporting skin regeneration and functional recovery.

FAQs

Frequently Asked Questions

-

What is the main role of gelatin scaffolds in tissue engineering?

Gelatin scaffolds primarily provide a 3D microenvironment for cell adhesion, proliferation, and differentiation while supporting nutrient and waste exchange. By adjusting porosity, pore size, and mechanical properties, scaffolds can mimic natural tissue structures and promote tissue regeneration. Functionalized scaffolds can also load growth factors or drugs to achieve directed differentiation or localized therapy, offering an ideal platform for bone, cartilage, skin, and vascular tissue repair.

-

What are the properties of a gelatin scaffold?

Gelatin scaffolds are three-dimensional porous materials that provide structural support and a growth environment for cells. Derived from partially hydrolyzed collagen, they offer the following advantages:

Excellent biocompatibility: Natural gelatin from collagen rarely triggers immune rejection, suitable for in vivo implantation.

Controllable degradability: Scaffold degradation rates can be tuned by adjusting crosslinking density or composite ratios to meet tissue repair needs.

Adjustable porosity: High porosity and interconnected networks provide space for cell migration, proliferation, and angiogenesis.

Good cell adhesion: Containing Arg-Gly-Asp (RGD) sequences to support cell attachment and differentiation.

Easy functionalization: Chemical crosslinking, composite materials, or bioactive molecule modifications allow controlled release of drugs or signaling molecules.

Other properties include mechanical strength, pore architecture, degradation rate, and bioactivity, all of which can be precisely tuned for research and industrial applications.

-

What types of gelatin scaffolds can you fabricate?

BOC Sciences can produce porous, fibrous, composite, and smart responsive gelatin scaffolds. Porous scaffolds feature uniform pores for cell adhesion, proliferation, and angiogenesis. Fibrous scaffolds mimic natural ECM microfibers to guide directional cell growth. Composite scaffolds combine nanomaterials or bioactive molecules to enhance mechanical strength and functional diversity. Smart responsive scaffolds respond to temperature, pH, or light to enable drug release or tissue function modulation.

-

Can gelatin scaffolds carry drugs or proteins?

Yes. Through functionalization and composite strategies, gelatin scaffolds can load drugs or proteins with controlled release. Optimized porosity and crosslinking allow precise regulation of release rates in vivo or in vitro. Scaffolds can also carry growth factors or specific proteins to guide cell differentiation and tissue regeneration.

-

Can scaffold mechanical properties and degradation rates be adjusted?

Yes. BOC Sciences can precisely tune scaffold mechanical properties and degradation rates using various strategies. Adjusting crosslinker type and density can enhance strength or slow degradation. Incorporating composites like nano-hydroxyapatite, carbon nanotubes, or cellulose nanoparticles further improves mechanical stability. Fabrication methods such as freeze-drying, electrospinning, or 3D printing also influence pore structure and degradation behavior.

-

Do you provide customized 3D-printed scaffold designs?

Yes. BOC Sciences offers full 3D printing customization. Using 3D bioprinting, we can precisely control pore size, internal channels, and overall structure based on client specifications. This technology supports custom tissue engineering, drug delivery platforms, and biomimetic organ models. Clients can provide design parameters or tissue structure requirements, and our team assists with material ratios, printing paths, and scaffold performance optimization.

-

Do you offer pilot-scale or mass production of scaffolds?

Yes. BOC Sciences provides gelatin scaffold services from lab-scale R&D to pilot-scale and small-batch production. Laboratory fabrication methods can be scaled up while ensuring stable, reproducible scaffold performance. Raw material quality, crosslinker usage, fabrication conditions, and post-processing are strictly controlled to ensure mechanical properties, biocompatibility, and functionalization meet project requirements.