Polylactic Acid (PLA) Services

Browse by

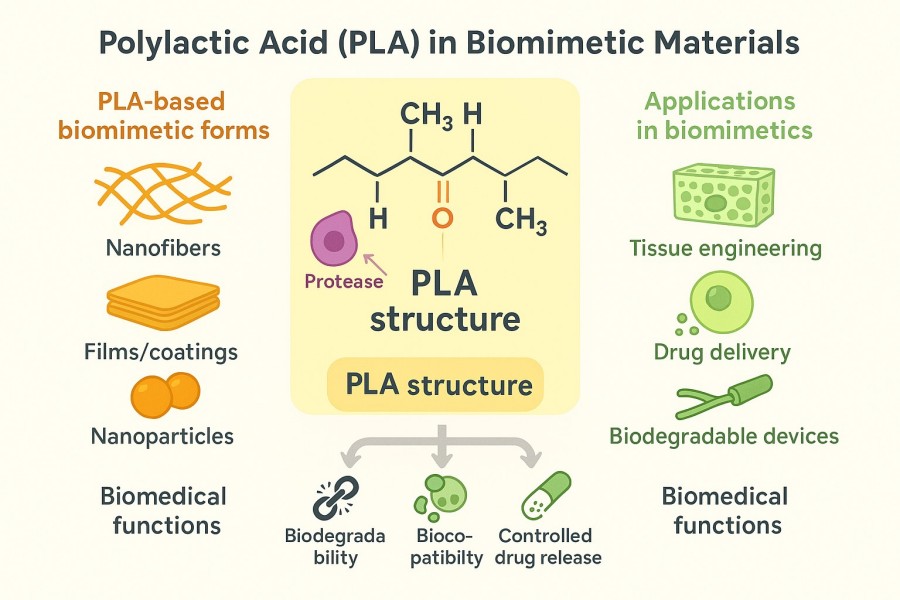

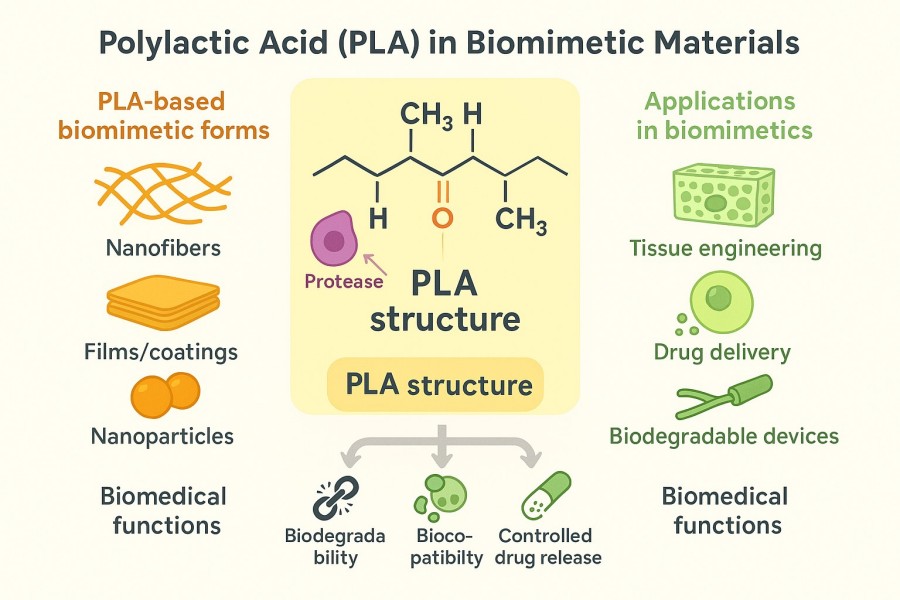

Polylactic acid (PLA) is a biobased thermoplastic polyester derived from renewable resources such as corn starch, sugarcane, and cassava. It is formed through the polycondensation or ring-opening polymerization of lactic acid monomers, resulting in long-chain polymers with excellent biocompatibility, biodegradability, and thermoplastic processability. In biomimetic materials research, PLA has become a key foundational material in tissue engineering scaffolds, biomimetic membranes, drug delivery carriers, and bone and soft tissue repair due to its safety, controllable degradation, and versatile processing methods. BOC Sciences has extensive experience in the custom synthesis and development of PLA, offering control over molecular weight, crystallinity, and stereochemistry, while supporting copolymer modification, functionalization, and composite formation with natural polymers or nanoparticles. Combined with processing technologies such as 3D printing and electrospinning, as well as characterization techniques including GPC, DSC, and SEM, we ensure PLA materials have stable and controllable properties suitable for scaffolds, films, particles, coatings, and other biomimetic material formats, enabling efficient translation from R&D to industrial application.

What We Offer

PLA Biomimetic Materials Provided by BOC Sciences

BOC Sciences possesses extensive R&D experience and technical expertise in PLA and its biomimetic material applications. We provide not only high-quality PLA raw materials with controllable molecular weight but also personalized customization according to clients' research or production needs, including molecular weight adjustment, copolymer modification, and functional composite design. Leveraging mature processing technologies and advanced characterization methods, we support a wide range of PLA application formats, from 3D scaffolds, films and fiber mats, micro/nanoparticles, tubular structures, to hydrogels, functional fibers, and coatings.

Polylactic Acid Hydrogels

- Degradable, three-dimensional crosslinked hydrogel scaffolds that mimic the cellular microenvironment.

- Support loading of drugs or biofactors for sustained release and tissue repair functions.

- Mechanical properties and degradation rates can be tuned via physical or chemical crosslinking.

- Suitable for soft tissue engineering, wound repair, and biomimetic matrix construction.

- Design, synthesis, and functionalization support available.

- Fabricated via electrospinning or solution casting into nano- or microscale fiber mats.

- Porous structures mimic the extracellular matrix (ECM) to promote cell adhesion and tissue regeneration.

- Can be combined with antimicrobial agents, drugs, or functional nanoparticles to enhance bioactivity.

- Applicable for wound dressings, artificial skin, and basement membrane mimics.

- Multi-layer composite and functional modification support provided.

- Functional coatings for devices, scaffolds, and film surfaces.

- Provide uniform coverage with controllable thickness and surface modification options.

- Can incorporate antimicrobial agents, drugs, or bioactive molecules to enhance surface functionality.

- Support biomimetic protective layers, drug release layers, and functional surface modification.

- Coating process design, performance optimization, and long-term stability support available.

- Porosity and pore size adjustable, suitable for bone, soft tissue, and vascular tissue engineering.

- Fabrication methods include 3D printing, fused deposition modeling (FDM), and phase separation.

- Molecular weight, crystallinity, and degradation rates can be customized.

- Scaffolds can be combined with natural polysaccharides or inorganic materials to enhance bioactivity and mechanical properties.

- Mechanical performance optimization and biodegradation matching solutions provided.

- Prepared using emulsion solvent evaporation, nanoprecipitation, or double emulsion methods.

- Efficiently encapsulate drugs or biofactors for precise controlled release.

- Surface modification or natural polysaccharide composites can enhance biomimetic delivery performance.

- Support drug delivery, tissue engineering factor release, and biomimetic controlled release system development.

- Services include particle size distribution, drug loading efficiency, and release kinetics optimization.

- Electrospinning, melt spinning, and multi-filament fiber preparation options available.

- Fiber diameter and alignment adjustable to mimic natural ECM structures.

- Can be combined with antimicrobial agents, drugs, or nanoparticles to enhance functionality.

- Suitable for tissue engineering scaffolds, skin repair, and functional textile development.

- Support for fiber mat design, surface modification, and multi-layer composites provided.

Polylactic Acid Tubular Constructs

- Hollow tubular structures suitable for vascular scaffolds and nerve conduits.

- Fabrication methods include rotational molding, thermal stretching, and 3D printing.

- Can incorporate bioactive factors or electroactive materials to optimize tissue regeneration.

- Wall thickness, pore structure, and mechanical properties customizable.

- Complete design solutions provided to guide cell growth and functional recovery.

Polylactic Acid Composite Materials

- PLA composites with hydroxyapatite, chitosan, gelatin, and other materials.

- Enhance mechanical properties, degradation control, and bioactivity.

- Ratios and surface modifications can be optimized for bone or soft tissue applications.

- Support drug-controlled release and functional scaffold applications.

- Material design, composite processing, and fabrication optimization services provided.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Customized PLA Services for Biomimetic Materials

As a global leader in polymer materials and custom services, BOC Sciences has extensive experience and technical expertise in PLA. We provide not only high-quality PLA raw materials with controllable molecular weight but also customized synthesis and functional modifications according to clients' biomimetic material requirements. Whether optimizing mechanical properties, tuning degradation rates, or enhancing bioactivity, we offer full-process technical solutions, enabling researchers, developers, and manufacturers to achieve high-performance, highly controllable biomimetic materials for innovative research and product development.

1High-Quality PLA Raw Materials

- Multiple molecular weights: low, medium, and high molecular weight PLA to meet different mechanical performance and degradation requirements.

- Various stereochemistries: support PLLA, PDLA, PLDLLA, and other lactic acid polymer types for diverse biomimetic applications.

- Stable supply: rigorous quality control ensures consistent performance of each batch, supporting both research and industrial production.

2Customized Synthesis Services

- Molecular weight control: tailor PLA chain lengths to achieve precise matching of degradation rates and mechanical performance.

- Copolymer modification: PLA copolymerized with other polymers or monomers to improve thermal stability, flexibility, or bioactivity.

- Functional modification: surface grafting or composite formation with bioactive materials to meet tissue engineering, drug release, and biomimetic membrane requirements.

3Quality Control and Technical Assurance

- Rigorous quality system: each batch of PLA is tested for molecular weight, crystallinity, thermal properties, and biocompatibility.

- Analytical and characterization services: GPC, DSC, TGA, SEM, and other techniques support research data verification and industrial-scale production.

- Customized reports: detailed performance reports provided to ensure traceability and reliable application of materials.

4Biomimetic Material Development Solutions

- Application consultation: guidance on material selection, structural design, and processing methods for various tissue engineering and biomimetic scenarios.

- Composite material solutions: support PLA composites with inorganic minerals, natural polysaccharides, or nanoparticles to enhance biomimetic functionality.

- Product performance optimization: customized solutions for mechanical properties, degradation rates, and bioactivity enhancement.

Advantages

Advantages of PLA Development Services

- High-Quality Raw Material Supply: We provide PLA raw materials with various molecular weights, crystallinities, and stereochemistries, ensuring controllable mechanical properties and degradation rates to meet both research and industrial production requirements.

- Customized Synthesis Services: Supports PLA chain length control, copolymer modification, and functionalization to meet the personalized design needs of scaffolds, films, particles, and composite materials.

- Advanced Processing Technologies: Offers 3D printing, fused deposition modeling (FDM), electrospinning, and rotational molding, supporting complex structures and high-precision fabrication.

- Composite Material Development: PLA can be combined with natural polysaccharides, minerals, or nanomaterials to enhance bioactivity, mechanical properties, and controlled release capability for diverse biomimetic applications.

- Micro/Nanoparticle Fabrication: Provides emulsion solvent evaporation, double emulsion, and nanoprecipitation methods to ensure efficient encapsulation of drugs or biofactors with precise controlled release.

- Hydrogel and Coating Technologies: Supports development of degradable hydrogels, tubular coatings, and functional surface coatings, enabling tuning of mechanical properties, degradation rates, and surface functionality.

- Strict Quality Control: Employs multiple characterization techniques including GPC, DSC, TGA, and SEM for full-process quality monitoring, ensuring traceability of both raw materials and final products.

- Technical Support and Process Optimization: Provides material selection, structural design, processing solutions, and functional optimization based on application requirements to enhance R&D efficiency and product competitiveness.

Service Process

End-to-End PLA Development and Application Workflow

The application of polylactic acid in biomimetic materials is extensive and complex. To meet the diverse needs of researchers, developers, and manufacturers, BOC Sciences offers a systematic, full-process PLA development and application service. From raw material selection and custom synthesis to processing, functional modification, and performance optimization, we provide efficient, reliable, and controllable solutions, ensuring every step meets the rigorous requirements of biomimetic materials research and industrial development.

1Raw Material Consultation and Selection

We provide PLA raw materials with different molecular weights, stereochemistries, and crystallinities according to client application needs. Based on mechanical properties and degradation rate requirements, we recommend the most suitable materials. Project goals are evaluated to propose targeted material selection strategies, laying a solid foundation for subsequent custom synthesis and processing, and ensuring materials are highly compatible with biomimetic applications.

2Custom Synthesis and Functional Modification

Depending on the application scenario, we offer customized synthesis services including PLA chain length control, copolymer modification, and surface functionalization. Degradation rate, mechanical properties, and bioactivity can be precisely tuned at the molecular level. Composite formation with natural polysaccharides, minerals, or nanoparticles is supported to achieve personalized designs for scaffolds, films, particles, and composite materials, meeting both research and industrial development needs.

3Processing and Structural Optimization

BOC Sciences employs 3D printing, FDM, electrospinning, rotational molding, and other technologies to fabricate PLA materials in various forms. Structural parameters such as porosity, fiber diameter, and tube wall thickness are optimized according to application goals. Processing conditions are controlled to ensure optimal mechanical properties, cell compatibility, and functionality.

4Composite Material and Functional Development

We develop PLA-based composites by incorporating natural polymers, inorganic minerals, or functional nanoparticles. Through ratio optimization, surface modification, and process control, mechanical properties are enhanced, bioactivity improved, and controlled release capability adjusted. This service is suitable for bone and soft tissue engineering, drug delivery, and biomimetic membrane development, meeting diverse application scenarios.

5Characterization and Quality Control

Comprehensive characterization services are provided, including molecular weight (GPC), thermal properties (DSC/TGA), microstructure (SEM), and mechanical testing. A strict quality control system ensures stable and traceable performance of every batch of PLA raw materials and products, providing reliable data for research validation and industrial production.

6Technical Support and Application Optimization

Throughout the PLA development process, BOC Sciences provides professional technical consulting, offering optimized solutions for material selection, structural design, processing, and functional modification. We help clients solve technical challenges in R&D, accelerate biomimetic materials research and product development, improve project efficiency and market competitiveness, and facilitate efficient translation of scientific outcomes.

Applications

Key Applications of PLA in Biomimetic Materials

Polylactic acid's biodegradability, biocompatibility, and versatile processing properties make it an indispensable core material for biomimetic materials development. PLA is widely used in tissue engineering scaffolds, drug-controlled release carriers, wound repair membranes, bone and soft tissue regeneration, as well as vascular and nerve conduits. Leveraging rich PLA R&D experience and full-process technical capability, BOC Sciences provides one-stop support from raw material selection, custom synthesis, processing, to composite modification, ensuring that each PLA material meets the mechanical, degradation, and biofunctional requirements of biomimetic applications, providing strong support for innovative research and product development.

Tissue Engineering Scaffold Materials

- Porous Scaffold Design: PLA scaffolds are typically fabricated via phase separation, FDM, 3D printing, or bubble templating. Porosity and pore size can be adjusted to optimize cell infiltration and nutrient diffusion.

- Degradation and Mechanical Matching: PLA degrades into lactic acid, which can be absorbed by the body, avoiding secondary surgery. Scaffold degradation rates can be tuned by adjusting molecular weight or copolymer composition to match tissue regeneration rates for bone, soft tissue, or vascular applications.

- Functional Modification: To enhance bioactivity, PLA scaffolds can be combined with natural polysaccharides (gelatin, chitosan, alginate) or surface-loaded with growth factors for biomimetic signaling.

Degradable Biomimetic Fibers and Films

- Electrospun Nanofibers: PLA electrospinning produces fiber diameters from tens to hundreds of nanometers. The porous structure mimics the extracellular matrix (ECM), facilitating cell adhesion and tissue regeneration.

- Functional Composite Films: PLA films can be combined with antimicrobials, drugs, inorganic nanoparticles, or natural polymers to improve mechanical strength, antibacterial properties, and bioactivity.

- Application Examples: Used in wound dressings, burn repair membranes, and artificial skin substitutes for biomimetic repair.

Biomimetic Bone Tissue Materials

- PLA/HA Composites: Combining PLA with hydroxyapatite (HA) provides mechanical support, improves bioactivity, and promotes osteoblast adhesion and mineralization.

- 3D Printed Bone Scaffolds: PLA-based composites allow 3D printing of complex bone defect scaffolds, precisely matching patient bone structures.

- Degradation and New Bone Formation: PLA degradation produces lactic acid, which slightly adjusts local pH to stimulate bone formation, while scaffolds are gradually replaced by new bone for tissue regeneration.

Drug-Controlled Release and Biomimetic Carriers

- Micro/Nanoparticle Carriers: PLA microspheres or nanoparticles can encapsulate drugs or bioactive factors for targeted delivery and controlled release.

- Biomimetic Delivery Systems: Surface modification or composite formation with natural polymers allows PLA carriers to mimic the cellular microenvironment, optimizing drug release kinetics and biocompatibility.

- Application Scenarios: Local tumor drug release, wound healing factor delivery, and growth factor delivery in tissue engineering.

FAQs

Frequently Asked Questions

-

Is PLA actually plastic?

Polylactic acid (PLA) is a biodegradable thermoplastic. Although derived from natural sources such as corn or sugarcane, it possesses the physical characteristics of plastics. PLA can be processed by injection molding, extrusion, or 3D printing and is widely used in packaging, films, scaffolds, and biomimetic material development, offering both environmental friendliness and processing versatility.

-

Is PLA 100% biodegradable?

PLA is biodegradable, but complete degradation in natural environments requires specific conditions, such as industrial composting (high temperature and humidity). Under these conditions, PLA can be broken down by microorganisms into water and carbon dioxide. Its degradation performance can be adjusted via molecular weight, crystallinity, and copolymer modification, making it suitable for biomimetic scaffolds, medical films, and degradable packaging materials.

-

Is PLA natural or synthetic?

PLA is a semi-synthetic polymer produced by chemically polymerizing or ring-opening polymerizing lactic acid derived from natural sources. Although the raw materials come from plants such as corn or sugarcane, synthesis allows control over molecular weight and crystallinity, giving PLA excellent mechanical properties, degradation rates, and processing adaptability for biomimetic and medical applications.

-

Which natural materials is PLA made from?

PLA is primarily derived from starch-containing plants such as corn, sugarcane, and cassava. Lactic acid is produced through fermentation and then chemically polymerized or ring-opening polymerized to form PLA. These natural sources ensure renewability and biodegradability, making PLA suitable for eco-friendly plastics, degradable packaging, and biomimetic scaffolds and tissue engineering materials.

-

What is polylactic acid used for?

PLA has broad applications in degradable packaging, disposable tableware, 3D printing filaments, and biomimetic material research. It can be fabricated into scaffolds, films, nano/microparticles, hydrogels, and coatings for use in tissue engineering, drug delivery, and wound repair. PLA combines environmental benefits with excellent processing properties, making it ideal for research and industrial development.

-

What are the biomedical applications of polylactic acid?

PLA is widely used in the biomedical field for tissue engineering scaffolds, biodegradable surgical sutures, drug-controlled release carriers, and wound repair membranes. Molecular weight, crystallinity, and functional modifications can be tuned to match mechanical properties with degradation rates, supporting bone, soft tissue, and vascular engineering, and enhancing biocompatibility and controlled degradability for biomimetic materials and medical device applications.

-

How is lactic acid manufactured?

Lactic acid is typically produced by fermenting starch-rich plants such as corn, sugarcane, or cassava, followed by chemical or enzymatic purification. During fermentation, microorganisms convert sugars into lactic acid, which can then be purified, concentrated, and lactonized to produce PLA feedstock. This process ensures renewable lactic acid sources while providing reliable raw materials for PLA custom synthesis, molecular weight control, and functional development.

Polylactic Acid Fiber Preparation

Polylactic Acid Fiber Preparation

Polylactic Acid Scaffold Preparation

Polylactic Acid Scaffold Preparation

Polylactic Acid Microsphere Preparation

Polylactic Acid Microsphere Preparation

Polylactic Acid Coating Preparation

Polylactic Acid Coating Preparation

Polylactic Acid Film Preparation

Polylactic Acid Film Preparation