Nanocellulose Preparation

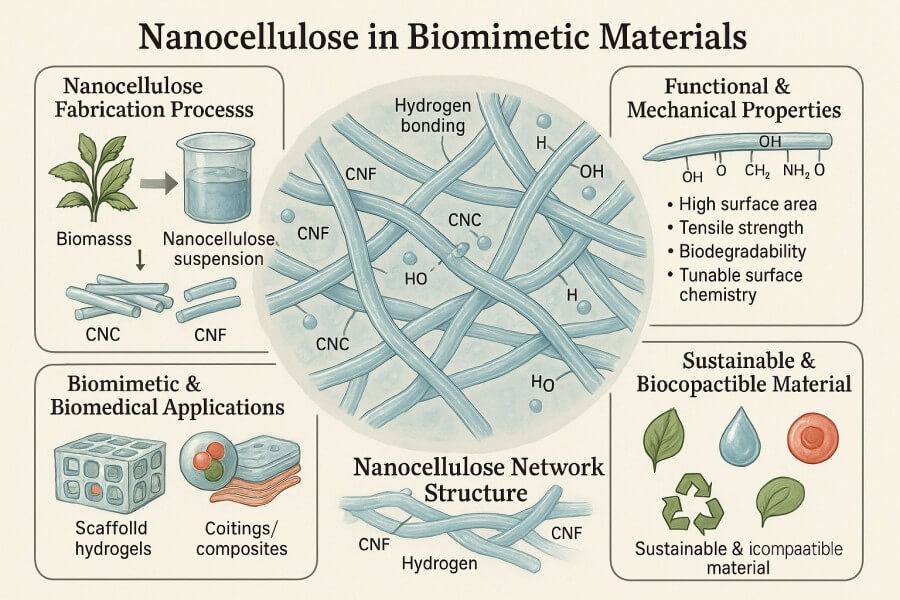

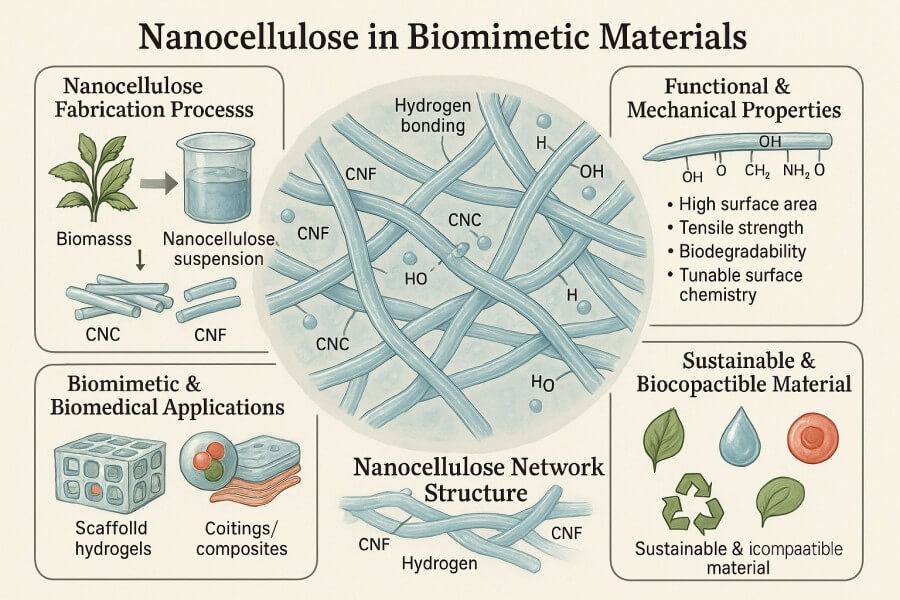

Nanocellulose is a nanoscale fibrous material extracted from natural cellulose or obtained through chemical and physical modification. Its key feature is having at least one dimension within the nanoscale range (1–100 nm) while retaining the chemical properties and biodegradability of cellulose. As a renewable, eco-friendly, and high-performance nanomaterial, nanocellulose has attracted widespread attention in recent years. It not only inherits the biodegradability and renewability of cellulose but also exhibits excellent mechanical, thermal, and optical properties due to its unique nanoscale structure. Nanocellulose is gradually becoming a key component in advanced materials and green technologies. BOC Sciences is dedicated to providing global biomimetic materials researchers and manufacturers with comprehensive nanocellulose production, synthesis, and development services, including the custom preparation, analysis, modification, and application support for bacterial nanocellulose, cellulose nanocrystals, cellulose nanofibers, and their derivatives. Through a scientific service workflow and flexible customization capabilities, we help clients achieve breakthroughs in nanocellulose research and industrialization.

What We Offer

Nanocellulose Services and Expertise at BOC Sciences

To support research, development, and production in the field of biomimetic materials, BOC Sciences offers multiple types of nanocellulose and demonstrates significant advantages in preparation, functionalization, composite development, and scale-up production. Whether for laboratory samples, pilot-scale trials, or mass production, we provide end-to-end, highly controllable, and high-quality nanocellulose solutions.

Bacterial Nanocellulose (BNC)

- Features: High purity, free of lignin and hemicellulose; prominent 3D network structure; excellent biocompatibility.

- Applications: Medical dressings, tissue engineering scaffolds, functional coatings, and biomimetic materials.

- Service Capabilities: Custom fermentation preparation, morphology control, and functional modification; support from small-scale validation to pilot production.

Cellulose Nanocrystals (CNCs)

- Features: Highly crystalline rod- or needle-shaped nanofibers; strong rigidity; controllable dimensions.

- Applications: Composite reinforcement, film materials, optical devices, and drug delivery systems.

- Service Capabilities: Acid hydrolysis preparation, dispersion optimization, and surface functionalization to meet diverse composite design requirements.

Cellulose Nanofibers (CNFs)

- Features: Flexible nanofibers capable of forming network structures; micron-scale length, nanoscale diameter.

- Applications: Reinforced composites, films, coatings, hydrogels, and biomimetic structural materials.

- Service Capabilities: Mechanical nanofibrillation, chemical-assisted processing, and functional modification; support for multiple dispersion strategies and composite designs.

Nanocellulose Coatings

- Features: Forms uniform thin films on various substrates with high adhesion and functionalization potential.

- Applications: Protective coatings, smart surfaces, self-cleaning, and antibacterial coatings.

- Service Capabilities: Formulation development, spray/dip coating preparation, and surface functional customization to meet industrial application requirements.

Nanocellulose Films

- Features: Transparent, high-strength, and flexible; combines mechanical and optical performance.

- Applications: Flexible electronics, optical devices, packaging materials, and biomimetic membrane structures.

- Service Capabilities: Solution casting, hot-press molding, and surface modification; support for customized thickness and performance.

Nanocellulose Hydrogels

- Features: 3D network structure with high water absorption; tunable mechanical strength and functionality.

- Applications: Tissue engineering scaffolds, controlled drug delivery carriers, smart materials, and food thickeners.

- Service Capabilities: Hydrogel formulation development, mechanical property optimization, and chemical functionalization; support from laboratory to pilot-scale production.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Nanocellulose Production and Custom Development Services

BOC Sciences provides full-process, one-stop nanocellulose production and custom development services, focused on supporting biomimetic materials research. Leveraging years of experience in polymer chemistry and biochemistry, we offer comprehensive solutions from raw material selection, preparation, functional modification, to application development, ensuring nanocellulose meets precise requirements in mechanical performance, functionality, and composite applications.

1Raw Material and Type Customization

- Diverse material selection: plant fibers, algal fibers, bacterial fermentation cellulose.

- High purity and low impurities to meet research and industrial needs.

- Pre-treatment options available to improve nanofibrillation efficiency and performance.

2Multiple Preparation Methods

- Physical: high-pressure homogenization, ultrasonication, grinding for flexible CNFs.

- Chemical: acid hydrolysis for CNCs; TEMPO oxidation for improved dispersion and functionalization.

- Biological: bacterial fermentation for BNC, yielding pure, highly crystalline nanocellulose.

3Nanostructure Control

- Precise control over fiber diameter, length, and crystallinity.

- Ability to produce rod-shaped, needle-shaped, or network-structured nanocellulose.

- Meets biomimetic research requirements for structural and mechanical performance.

4Surface Functionalization and Modification

- Hydroxylation, esterification, etherification, and graft copolymerization.

- Impart hydrophobicity, hydrophilicity, conductivity, or bioactivity to cellulose.

- Supports functionalization needs for films, coatings, hydrogels, and composites.

5Composite Optimization and Industrial Scale Support

- Dispersant selection and solvent optimization to ensure uniform distribution in composites.

- Enhance mechanical properties, transparency, and functional performance of composites.

- Support from lab-scale trials to pilot-scale production for all R&D stages.

6Performance Optimization and Application Development

- Mechanical performance tuning: control fiber length, crystallinity, and dispersion.

- Functional control: surface chemistry modification for adsorption, catalysis, optical, or bioactive functions.

- Composite design: combine with polymers, nanoparticles, or conductive materials for multifunctional biomimetic materials.

- Application development: films, coatings, hydrogels, smart materials, and composite structural materials.

Characterization

Nanocellulose Analysis and Quality Assurance

To ensure reliable and reproducible performance of nanocellulose products, BOC Sciences provides comprehensive analytical testing and quality assurance services. Using advanced instrumentation, standardized workflows, and systematic data reporting, we guarantee that each batch of nanocellulose meets structural, mechanical, thermal, and functional specifications for research or industrial use. Whether CNF, CNC, or BNC, BOC Sciences delivers full-spectrum analysis to help clients optimize material performance and application outcomes.

| Test Category | Test Item | Analytical Method | Service Advantage |

|---|

| Nanostructure Characterization | Fiber diameter, length, morphology, distribution | TEM, SEM, AFM | Accurate analysis of nanoscale dimensions and morphology to support material design and composite optimization. |

| Crystallinity & Structural Analysis | Crystallinity, crystal type | XRD | Ensures consistent CNC/CNF structure, improving predictive accuracy for composite mechanical performance. |

| Chemical Composition & Functionalization | Hydroxyl content, degree of surface modification, functional group distribution | FTIR, NMR, XPS | Precisely verifies chemical modification effectiveness, ensuring functional performance. |

| Thermal Properties | Thermal stability, glass transition temperature, decomposition temperature | TGA, DSC | Ensures material thermal stability during processing and application. |

| Mechanical Properties | Tensile strength, modulus, toughness | Tensile tester, nanoindentation | Provides reliable mechanical data for composites and films. |

| Dispersion & Uniformity | Dispersion stability, aggregation level | DLS, Zeta potential | Optimizes dispersion conditions, improving uniformity and performance in composites. |

| Hydrogel & Film Performance | Water absorption, swelling ratio, transmittance, thickness uniformity | Water absorption test, UV-Vis, thickness measurement | Validates performance of hydrogels, films, and coatings for development purposes. |

Advantages

Why Choose BOC Sciences for Nanocellulose Services?

- Extensive Preparation Experience: With years of experience in cellulose and nanocellulose production, we efficiently prepare CNF, CNC, and BNC, adjusting dimensions, crystallinity, and dispersibility according to client requirements.

- Custom Synthesis and Modification Capability: Beyond basic preparation, we offer surface functionalization, grafting, and crosslinking modifications, providing diverse options for the development of nanocellulose coatings, hydrogels, and films.

- End-to-End Analysis and Characterization: Equipped with advanced analytical instruments, we comprehensively evaluate particle size, crystallinity, specific surface area, thermal properties, mechanical performance, and dispersibility to ensure consistent, reliable material quality.

- Diverse Application Support: Based on client needs in biomimetic materials, nanocomposites, 3D printing, medical, and electronic applications, we provide nanocellulose application consulting and material optimization solutions to accelerate R&D and industrialization.

- Scale-Up Production Capability: From small laboratory batches to pilot-scale production, we offer flexible manufacturing services to meet the needs of different R&D and commercialization stages.

- Technical Consultation and R&D Support: Our expert team provides comprehensive support in nanocellulose material design, process optimization, and application development, helping clients improve R&D efficiency and product performance.

Service Process

Nanocellulose Custom Services: Process at BOC Sciences

To meet diverse client requirements in nanocellulose production and development, BOC Sciences offers a systematic, scientific, and highly customized service workflow covering the full lifecycle from concept design to mass production. Our workflow focuses not only on nanocellulose preparation but also on functional modification, performance optimization, and application development, ensuring clients receive high-quality, reproducible, and high-value nanocellulose materials.

1Requirement Communication and Project Evaluation

- Detailed Requirement Collection: Understand client objectives in nanocellulose applications through calls, video, or on-site meetings, including material type (CNC, CNF, BNC), size specifications, functional requirements, and application scenarios.

- Project Feasibility Analysis: Evaluate preparation methods, costs, and technical feasibility based on client needs and propose preliminary solutions.

- Technical Consultation Support: Provide clients with the latest nanocellulose preparation technologies, modification methods, and industry trends to help design a scientifically sound R&D plan.

2Solution Design and Process Planning

- Customized Process Design: For cellulose nanocrystals, cellulose nanofibers, or bacterial nanocellulose, design optimal preparation workflows, including raw material selection, pre-treatment methods, nanofibrillation approaches, and modification strategies.

- Functionalization Planning: Develop surface functionalization and composite strategies for nanocellulose coatings, films, or hydrogels based on client requirements.

- Cost and Time Optimization: Optimize process parameters to control development cycles and costs while ensuring material performance, delivering cost-effective solutions.

3Lab-Scale Preparation and Validation

- Small-Scale Laboratory Preparation: Conduct lab-scale nanocellulose production to validate process parameters and material controllability.

- Preliminary Performance Testing: Characterize particle size, crystallinity, specific surface area, dispersibility, and mechanical properties to ensure materials meet client R&D requirements.

- Feedback and Adjustment: Adjust preparation conditions based on lab results to optimize nanocellulose morphology, dispersibility, and stability, laying the foundation for pilot and mass production.

4Process Optimization and Functional Modification

- Fine Parameter Control: Precisely control the size of cellulose nanofibers and nanocrystals by adjusting temperature, pH, ultrasonic intensity, and homogenization pressure.

- Functional Modification: Offer TEMPO oxidation, esterification, etherification, graft polymerization, and other modification services to produce high-performance nanocellulose coatings, hydrogels, or films.

- Composite Material Development: Combine nanocellulose with polymers, metal nanoparticles, or conductive materials to meet the specific performance requirements of biomimetic materials, 3D printing, and electronic materials.

5Pilot-Scale and Mass Production Support

- Pilot Process Scale-Up: Expand lab-scale successes to pilot scale, optimizing equipment parameters and production conditions to ensure batch-to-batch consistency.

- Mass Production Verification: Provide production capabilities from gram to kilogram scale or larger, supporting the transition from R&D to commercialization.

- Production Controllability: Monitor particle size distribution, crystallinity, specific surface area, and dispersibility during pilot and mass production to ensure stable material performance.

6Performance Analysis and Quality Assurance

- Comprehensive Characterization Services: Conduct particle size analysis, crystallinity testing, specific surface area measurement, mechanical performance evaluation, thermal property analysis, and dispersibility testing for nanocellulose.

- Customized Reports: Deliver detailed performance analysis reports to support R&D, publications, and product development.

- Quality Control System: Ensure each batch of nanocellulose materials meets client standards for performance and purity, reducing R&D and production risks.

Applications

Applications of Nanocellulose in Biomimetic Materials

Nanocellulose, with its nanoscale structure, high specific surface area, excellent mechanical properties, and biocompatibility, shows broad potential in biomimetic materials. It can mimic natural tissue structures and impart intelligent responsiveness to composites, making it a crucial raw material for biomimetic R&D and industrialization. BOC Sciences provides high-performance, customizable nanocellulose and development support to help clients transform innovative concepts into practical products.

High-Performance Biomimetic Composites

Nanocellulose serves as the foundational scaffold for biomimetic structures, forming composites with polymers, ceramics, or metals to achieve lightweight, high-strength, and high-toughness materials. Its nanoscale network structure enhances mechanical performance while maintaining flexibility and stability. Applications include aerospace materials, lightweight automotive components, and high-performance sporting goods.

Flexible Transparent Films

Nanocellulose films offer high transparency, flexibility, and controllable mechanical strength, suitable for flexible electronics, optical devices, and biomimetic membrane structures. Surface chemical modifications enable conductivity, antibacterial properties, or optical filtering, providing a reliable foundation for smart biomimetic devices and high-end electronics.

Intelligent Hydrogels and Tissue Engineering Scaffolds

Nanocellulose hydrogels have 3D network structures and excellent water absorption, simulating natural tissue microenvironments. Through chemical modification or incorporation of functional materials, hydrogels can provide controlled drug release, environmental responsiveness, cell support, and mechanical matching. They are widely used in tissue engineering, biomimetic medical materials, and smart responsive biomimetic systems.

Functional Coatings and Surface Modification

Nanocellulose can be used to develop biomimetic surface coatings. By controlling coating thickness, density, and surface chemistry, materials can achieve waterproofing, antibacterial, self-cleaning, or smart responsive functionalities. These coatings are applied in electronics, medical devices, smart packaging, and environmentally friendly materials, providing reliable solutions for multifunctional biomimetic applications.

FAQs

Frequently Asked Questions

-

What is nanocellulose?

Nanocellulose is a highly versatile material derived from cellulose, consisting of nanoscale fibrils or crystals. It exhibits remarkable mechanical strength, large surface area, and biodegradability. Nanocellulose is used in advanced materials, composites, coatings, hydrogels, and electronics. Its unique nanoscale structure enables applications that require high tensile strength, transparency, or enhanced barrier properties, making it valuable across pharmaceuticals, food, packaging, and biomedical industries.

-

What is the difference between cellulose and nanocellulose?

Cellulose is a natural polymer composed of glucose units forming fibers, while nanocellulose refers to cellulose processed into nanoscale forms such as cellulose nanocrystals (CNCs) or cellulose nanofibers (CNFs). Nanocellulose has significantly higher surface area, mechanical strength, and tunable properties compared to bulk cellulose. Its nanoscale dimensions enable applications in high-performance composites, drug delivery systems, and advanced coatings, where conventional cellulose cannot provide sufficient strength or surface functionality.

-

How to make nanocellulose?

Nanocellulose is produced by mechanical, chemical, or enzymatic treatment of cellulose. Mechanical methods include high-pressure homogenization, grinding, or ultrasonication to break down fibers. Chemical methods, such as acid hydrolysis or TEMPO-mediated oxidation, selectively remove amorphous regions, yielding nanocrystals or nanofibers. Enzymatic treatments use cellulases to assist fiber disintegration. The production method affects particle size, crystallinity, surface chemistry, and suitability for specific industrial or biomedical applications.

-

What are the main properties of nanocellulose?

Nanocellulose exhibits high tensile strength, low density, large surface area, and biodegradability. It can form transparent films, hydrogels, or reinforced composites. Surface modification allows functionalization for adhesion, water absorption, or drug delivery. Its nanoscale structure also enables rheological control in suspensions. Non-toxic and renewable, nanocellulose finds use in coatings, inks, food stabilization, biomedical scaffolds, and green materials, combining mechanical performance with sustainability.

-

What are the different types of nanocellulose?

The main types of nanocellulose include cellulose nanocrystals (CNCs), cellulose nanofibers (CNFs), and bacterial nanocellulose (BNC). CNCs are rigid rod-like structures obtained via acid hydrolysis. CNFs are long, flexible fibrils produced by mechanical or enzymatic treatments. BNC is biosynthesized by bacteria, forming a pure, highly crystalline network. Each type has unique dimensions, crystallinity, and surface chemistry, influencing applications in composites, hydrogels, electronics, and biomedical fields.

-

What is nanocellulose used for?

Nanocellulose has broad industrial and biomedical applications. It reinforces composites, improves barrier properties in packaging, stabilizes emulsions in food, and enhances rheology in coatings or inks. In biomedicine, it serves as wound dressings, drug carriers, or tissue scaffolds. Its nanoscale structure allows use in electronics, sensors, and flexible films. Renewable, biodegradable, and biocompatible, nanocellulose is increasingly integrated into green materials, sustainable packaging, cosmetics, and energy storage, providing functional performance that traditional cellulose cannot achieve.

-

What is cellulose nanocrystals?

Cellulose nanocrystals (CNCs) are rigid, rod-shaped nanostructures extracted from cellulose fibers via acid hydrolysis. They possess high crystallinity, mechanical strength, and large surface area. CNCs can form stable suspensions, transparent films, or reinforce composites. Their surface chemistry allows functionalization for applications in coatings, adhesives, biomedical scaffolds, and sensors. CNCs are lightweight, renewable, and biodegradable, making them a versatile nanomaterial for high-performance applications in packaging, electronics, and biomedicine.

-

How to make cellulose nanocrystals?

Cellulose nanocrystals are commonly produced through controlled acid hydrolysis, which removes amorphous regions of cellulose fibers. Sulfuric or hydrochloric acids are used, resulting in rod-like crystalline domains. Post-hydrolysis steps include washing, neutralization, and sonication to obtain uniform suspensions. Alternative methods include enzymatic pretreatment or mechanical shearing to assist fiber breakdown. Production parameters such as temperature, acid concentration, and time affect particle size, crystallinity, and surface charge, which determine the CNCs' performance in specific applications.

-

What is cellulose nanofiber?

Cellulose nanofibers (CNFs) are long, flexible nanoscale fibrils derived from cellulose fibers. They have high aspect ratios, mechanical strength, and a large surface area, allowing them to form entangled networks and hydrogels. CNFs can be chemically modified to enhance compatibility with polymers or for specific applications in coatings, composites, biomedical scaffolds, and paper reinforcement. Compared to CNCs, CNFs are less crystalline but more flexible, making them suitable for applications requiring structural reinforcement, viscosity control, or functional surface properties.

-

How to make cellulose nanofiber?

Cellulose nanofibers are produced by mechanical disintegration of cellulose fibers, often combined with chemical or enzymatic pretreatments. Mechanical methods include high-pressure homogenization, microfluidization, grinding, or ultrasonication. Chemical pretreatments like TEMPO-mediated oxidation introduce charges to facilitate fiber separation. Enzymatic treatment with cellulases softens fibers and reduces energy consumption. The choice of method affects fiber diameter, length, surface chemistry, and functional properties, determining suitability for composites, films, hydrogels, or biomedical applications.