Chitosan Scaffold Preparation

Chitosan scaffold refers to a three-dimensional porous material constructed using chitosan as the primary component through physical, chemical, or composite techniques. This type of scaffold can mimic the microenvironment of the natural Extracellular Matrix (ECM), providing support for cell adhesion, proliferation, differentiation, and tissue regeneration. Chitosan scaffolds combine bioactivity with tunable mechanical properties, making them essential carriers in tissue engineering and biomimetic material research. BOC Sciences specializes in providing comprehensive chitosan scaffold preparation and development services for biomimetic materials, including porous scaffolds, nanofibrous scaffolds, hydrogel scaffolds, and functionalized scaffolds. We focus on optimizing material selection, scaffold structure design, and modification strategies to deliver chitosan-based scaffolds that meet diverse application requirements, supporting the entire workflow from basic research to industrial production. Whether it is bone tissue engineering chitosan scaffolds or biodegradable scaffolds chitosan, BOC Sciences provides tailored solutions.

What We Offer

Chitosan Scaffold Preparation Services by BOC Sciences

BOC Sciences offers comprehensive chitosan scaffold preparation services, covering various scaffold types from basic research to industrial development. We can customize scaffolds based on client application needs and research objectives, ensuring mechanical properties, pore architecture, and functionalization meet the requirements of biomimetic materials and tissue engineering. Whether it is porous scaffolds, nanofibrous scaffolds, composite scaffolds, or hydrogel scaffolds, we provide customized design, structural optimization, and functional modification services, ensuring every chitosan scaffold project achieves optimal performance and application outcomes.

Porous Scaffold

Porous scaffolds are the most common form of chitosan scaffolds, prepared via freeze-drying, bubble templating, or phase separation techniques.

- Pore tunability: By adjusting solution concentration, freezing rate, or crosslinking conditions, pore size (50–500 μm) and porosity (60–90%) can be controlled.

- Wide applicability: Suitable for soft tissue and bone tissue engineering, promoting cell infiltration and nutrient exchange.

- Composite applications: Can be combined with bioactive ceramics or biomolecules to enhance functionality.

Hydrogel Scaffold

Chitosan hydrogel scaffolds form a three-dimensional network through crosslinked chitosan and can swell in water, mimicking the hydrated environment of natural tissues.

- High biocompatibility: Soft and moist, suitable for soft tissue or cell suspension culture.

- Controlled degradation: Crosslinking density and chemical modifications regulate degradation rates.

- Drug carrier: Can embed drugs or growth factors for sustained release.

Nanofibrous Scaffold

Chitosan nanofibrous scaffolds are prepared using electrospinning technology.

- High surface area: Promotes cell adhesion and signal transmission.

- Strong biomimicry: Nanofiber structures resemble natural collagen fiber arrangements.

- Composite modification: Can be combined with synthetic polymers such as PLA or PCL to improve mechanical properties.

Composite Scaffold

Chitosan can be combined with natural or synthetic materials to create functional scaffolds:

- Bone repair composite scaffolds: Chitosan + hydroxyapatite/tricalcium phosphate, enhancing mechanical strength and mineralization.

- Soft tissue composite scaffolds: Chitosan + gelatin/alginate, providing elasticity and cell adhesion sites.

- Drug-functionalized scaffolds: Chitosan + drug carriers or nanoparticles for controlled drug release.

Tubular Scaffold

Suitable for nerve, vascular, and conduit tissue engineering, prepared through molding or self-assembly techniques.

- Nerve conduits: Guide axonal regeneration and improve repair with growth factors.

- Vascular scaffolds: Provide surfaces for endothelial cell adhesion and support vascular regeneration.

- Controllable structure: Inner diameter, wall thickness, and pore architecture can be designed according to application needs.

Film or Membrane Scaffold

Chitosan films are prepared via solution casting or spin-coating and are commonly used for wound coverage or tissue interface materials.

- Good breathability: Maintains a moist environment and prevents infection.

- Functionalization: Can load drugs, antimicrobial molecules, or growth factors.

- Flexible and tunable: Suitable for covering curved tissues or as intermediate layers in multilayer composites.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Chitosan Scaffold Development Technology at BOC Sciences

Our service capabilities cover chitosan scaffold preparation, porous structure and mechanical performance optimization, composite material development, as well as smart-responsive and drug carrier functionalization. By combining advanced fabrication techniques with customized design, we deliver efficient, reliable, and reproducible scaffold products that meet the requirements of scientific research, preclinical studies, and industrial production.

1Customized Scaffold Design

- Controllable porous structure: Adjust pore size (50–500 μm), porosity (60–90%), and pore distribution to optimize cell adhesion, migration, and nutrient diffusion.

- Mechanical property tuning: Select crosslinkers or composite materials to customize scaffold elasticity, stiffness, and compressive strength, suitable for soft tissue or bone tissue engineering.

- Flexible size and shape: Produce sheet-like, tubular, porous block, or hydrogel forms to support applications from small-scale laboratory tests to industrial production.

2Diverse Scaffold Forms

- Porous scaffolds: Prepared via freeze-drying, bubble templating, or phase separation, suitable for bone and soft tissue engineering.

- Hydrogel scaffolds: Form three-dimensional expandable networks via physical or chemical crosslinking, mimicking the hydrated extracellular matrix.

- Nanofibrous scaffolds: Electrospun high surface area fibers promote cell adhesion and tissue regeneration.

- Composite scaffolds: Chitosan combined with hydroxyapatite, gelatin, alginate, or PLA for multifunctional applications.

- Tubular and film scaffolds: Suitable for nerve conduits, vascular scaffolds, and wound coverage, providing flexibility and tunability.

3Functionalization and Modification Services

- Chemical modification: Amino or hydroxyl modifications combined with growth factors, drugs, or bioactive molecules enhance scaffold functionality.

- Bioactive composites: Incorporation of antimicrobials, anti-inflammatory drugs, or mineral components enables controlled drug release and tissue mineralization.

- Smart-responsive materials: Develop pH, temperature, or enzyme-responsive chitosan scaffolds for precise release and functional control.

4High-Quality Raw Material Assurance and Analysis

- Molecular weight and distribution analysis: Evaluate chitosan molecular weight and uniformity via GPC or viscosity methods.

- Degree of deacetylation determination: Analyze chitosan acetyl content using FTIR or NMR to ensure controlled degradability.

- Purity and impurity analysis: Conduct elemental analysis, ash content, and solution stability tests to ensure consistent raw material quality.

- Solubility and solution characterization: Use solubility and rheology tests to provide accurate parameters for scaffold preparation.

Advantages

Custom Chitosan Scaffold Services – Key Advantages

- Diverse scaffold types: Support porous, hydrogel, nanofibrous, composite, tubular, and film chitosan scaffold preparation, meeting research and industrial application needs.

- Customized design solutions: Control pore size, porosity, mechanical performance, and functionalization according to client requirements for highly controllable scaffold structure and performance.

- Composite material development: Combine chitosan with collagen, alginate, hydroxyapatite, and other materials to create high-performance, multifunctional scaffolds.

- Functionalization and modification services: Provide chemical modification, drug carrier, and responsive scaffold solutions for tissue engineering and drug-controlled release applications.

- High-quality raw material assurance: Use chitosan with tunable molecular weight and degree of deacetylation, with full characterization and analysis, ensuring biocompatibility and biodegradability.

- Full workflow support from research to industrial production: Cover laboratory trials, pilot optimization, and industrial-scale production, providing one-stop chitosan scaffold preparation and development services.

- Strict quality control system: Monitor porosity, mechanical properties, biocompatibility, and degradability to ensure consistent scaffold performance.

Service Process

Full Workflow of Chitosan Scaffold Preparation Services

Our workflow is meticulously designed to ensure seamless integration at every stage. From project initiation, solution design, and sample validation to process optimization, technical training, and long-term support, every step is centered on client needs, delivering efficient, reliable, and reproducible scaffold solutions. Whether for laboratory research, tissue engineering studies, or industrial-scale production, we are committed to helping clients accelerate project progress while ensuring scaffold performance and application outcomes are optimized.

1Project Requirement Communication

At the project initiation stage, we engage in in-depth communication with clients to clarify the required chitosan scaffold type, pore architecture, size range, and functionalization needs. By understanding research objectives and application scenarios, we provide precise guidance for subsequent design and fabrication, ensuring accurate project alignment from the start and minimizing development cycles and resource waste.

2Customized Solution Design

Based on client requirements, we provide comprehensive customized solutions for chitosan-based scaffolds, including material selection, pore architecture design, mechanical performance optimization, and functionalization strategies. The design process considers scaffold composites, drug carrier integration, or responsive modifications, ensuring scaffold performance meets the needs of tissue engineering, drug delivery, or biomimetic material research.

3Sample Preparation and Preliminary Validation

We rapidly produce laboratory-scale or pilot-scale samples using techniques such as freeze-drying, hydrogel formation, or electrospinning to achieve the target scaffold structure. Performance verification—including structure, porosity, mechanical properties, and bioactivity—is conducted to provide reliable data for process optimization and subsequent bulk production.

4Process Optimization and Scale-Up

Based on sample validation results and client feedback, we optimize fabrication parameters, including solution concentration, crosslinking conditions, and processing temperature. Our services support scaling from laboratory to pilot and industrial-scale production, ensuring scaffold structure, function, and performance remain consistent and reproducible across different scales.

5Technical Support and Application Training

We provide detailed operational guidance, process parameter documentation, and functional application training to help clients master chitosan scaffold fabrication techniques. Professional advice is offered for various applications such as tissue engineering, drug delivery, or 3D cell culture, improving R&D efficiency and accelerating translational outcomes.

6Continuous Service and Project Support

Throughout the project lifecycle, we offer ongoing technical support, including formulation optimization, quality monitoring, and exploration of new applications. We provide complete technical assurance and consulting services to ensure chitosan-based scaffold projects progress smoothly, meeting long-term requirements for research, preclinical studies, and industrial applications.

Applications

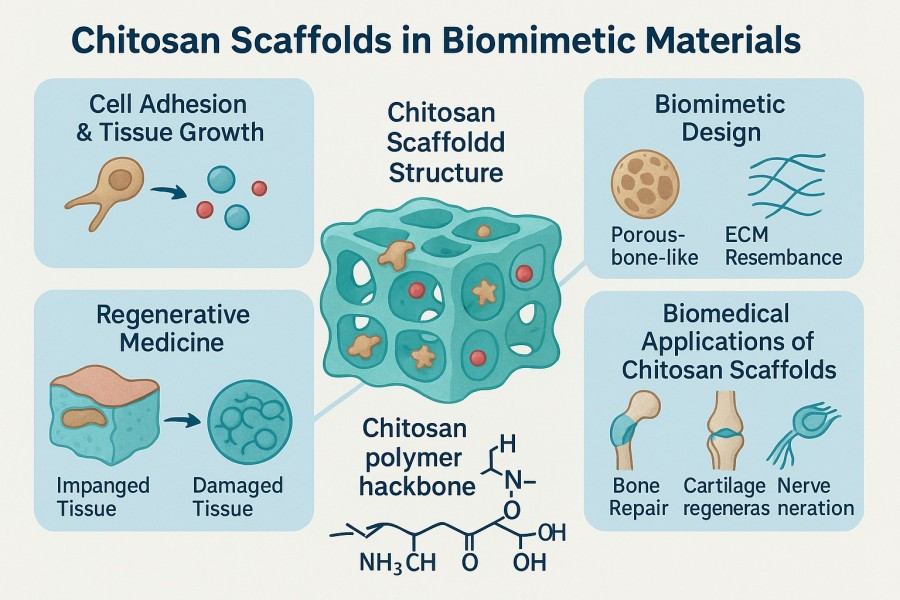

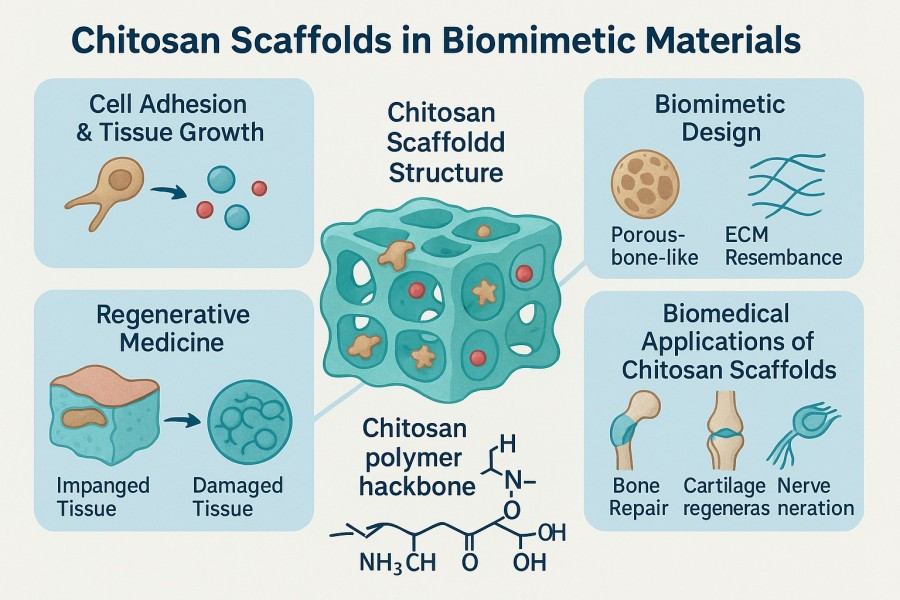

Applications of Chitosan Scaffolds in Biomimetic Materials

Due to their unique structure and bioactivity, chitosan scaffolds have diverse applications in biomimetic materials and tissue engineering. Biomimetic materials aim to replicate the structure and function of natural tissues to promote tissue repair, drug delivery, and medical device optimization. The main application areas of chitosan scaffolds in biomimetic materials include:

Tissue Engineering and Regenerative Medicine

- Soft tissue repair: Such as skin, vascular, and nerve tissues. Chitosan scaffolds can be combined with collagen, gelatin, or bioactive factors to enhance bioactivity and promote cell adhesion.

- Bone regeneration: Functional bone substitute materials are formed by combining chitosan with hydroxyapatite (HA) or tricalcium phosphate (TCP), improving mechanical strength and mineralization capacity.

- Nerve regeneration: Porous tubular chitosan scaffolds can guide nerve fiber growth, and integration with nerve growth factor (NGF) promotes damaged nerve repair.

Drug Controlled Release and Delivery Systems

- Local drug release: Pore structure regulates drug release rate for long-term sustained release, such as antibiotics, anti-inflammatory, or anticancer drugs.

- Multi-drug delivery: Scaffolds can load different drugs simultaneously for combination therapies, such as synergistic effects of anti-inflammatory and pro-angiogenic drugs.

- Responsive drug release: pH-sensitive or enzyme-sensitive chitosan modifications enable drug release in response to specific physiological environments.

Wound Repair Materials

- Antimicrobial dressings: Scaffold structure facilitates exudate absorption and gradual release of antimicrobial agents to prevent infection.

- Maintenance of a moist wound environment: Porous structures help sustain a moist microenvironment, accelerating epithelial cell migration and angiogenesis.

- Hemostatic materials: Chitosan has excellent hemostatic properties and can be combined with fibrin or gelatin to enhance blood clotting.

Cell Culture and 3D Cell Models

- Tumor models: Used to study the tumor microenvironment, drug screening, and pharmacokinetics.

- Stem cell culture: Provides suitable mechanical and chemical cues to promote differentiation into specific cell types.

- Organ-on-a-chip: Chitosan scaffolds can be used in microfluidic systems to simulate tissue functions in vitro.

FAQs

Frequently Asked Questions

-

What is a chitosan scaffold?

A chitosan scaffold is a three-dimensional scaffold material based on chitosan, widely used in tissue engineering and biomimetic material research. Its structure allows tunable porosity, pore size, and mechanical properties to mimic the natural extracellular matrix environment, supporting cell adhesion, proliferation, and differentiation. It can also integrate drugs, proteins, or growth factors for sustained release or functionalized applications, suitable for bone repair, soft tissue regeneration, and 3D cell culture models.

-

How to make chitosan scaffold?

Chitosan scaffolds are typically prepared using freeze-drying, bubble templating, phase separation, or electrospinning techniques. Chitosan is first dissolved in an acidic solution to form a homogeneous solution, and an appropriate fabrication method is chosen based on design requirements. By adjusting solution concentration, freezing rate, or crosslinking conditions, scaffolds with varying pore sizes, porosity, and mechanical properties can be produced, enabling customized designs for tissue engineering and drug delivery applications.

-

What are the features of collagen chitosan scaffold?

A collagen chitosan scaffold is a 3D scaffold formed by combining chitosan with collagen, integrating chitosan's degradability and collagen's cell compatibility. Its porous structure promotes cell adhesion and migration while supporting nutrient diffusion. This composite scaffold is commonly used in soft tissue regeneration, skin repair, and tissue engineering studies, and functionalized designs and mechanical optimization can be achieved by adjusting material ratios and crosslinking methods.

-

What applications are suitable for alginate chitosan scaffold?

Alginate chitosan scaffold is a composite scaffold of chitosan and alginate with good biocompatibility and tunable pore structure. Its high water retention makes it suitable for soft tissue engineering and 3D cell culture, and it can embed drugs or growth factors for sustained release. By adjusting composite ratios, crosslinking methods, and pore architecture, mechanical properties and degradation rates can be optimized, making it widely used in tissue repair and drug delivery research.

-

What are the advantages of biodegradable scaffolds chitosan?

Biodegradable chitosan scaffolds gradually degrade in vivo without generating toxic byproducts. Their porous structure supports cell infiltration and tissue regeneration, and degradation rate can be controlled via molecular weight, degree of deacetylation, and crosslinking methods. They can serve as drug carriers for sustained release and are suitable for bone tissue engineering, soft tissue repair, and 3D cell culture, providing controlled and efficient scaffolding for research and preclinical applications.

-

What is the use of chitosan hydroxyapatite scaffold?

Chitosan hydroxyapatite scaffold is a bone tissue engineering scaffold composed of chitosan and hydroxyapatite. Chitosan provides degradability and biocompatibility, while hydroxyapatite enhances mechanical strength and mineralization. Its porous structure supports cell adhesion, proliferation, and bone regeneration, and it can embed growth factors or drugs for functional applications, making it an important material for bone defect repair and tissue engineering research.

-

What are the characteristics of modified chitosan scaffold?

Modified chitosan scaffold is chemically or physically modified to enhance functional properties, such as drug delivery, responsive release, or improved cell adhesion. Modifications include amino or hydroxyl functionalization or active factor grafting, enabling adaptation to various applications. This scaffold can be used in tissue engineering, drug delivery, and biomimetic material research, providing controlled degradability, optimized mechanical properties, and enhanced functionality.